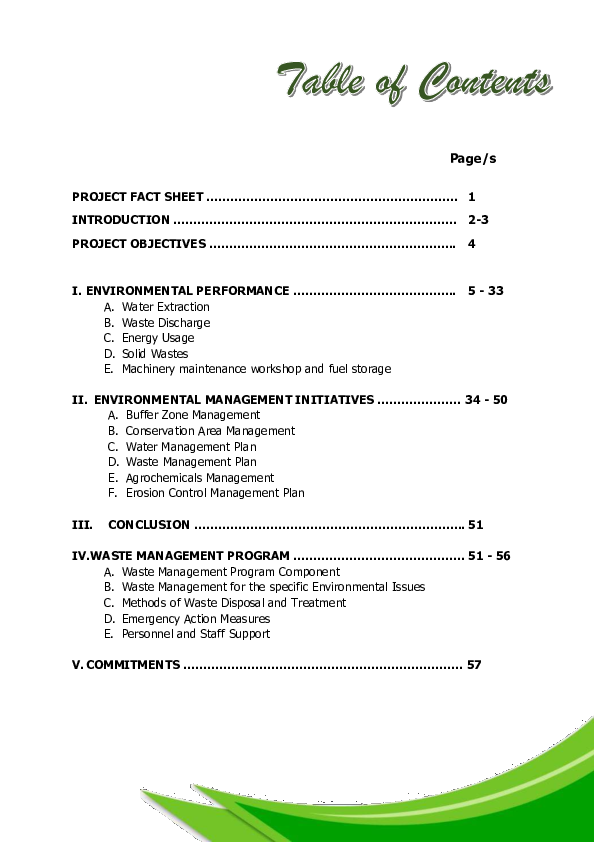

Page/s

PROJECT FACT SHEET ............................................................... 1

INTRODUCTION ....................................................................... 2-3

PROJECT OBJECTIVES .............................................................. 4

I. ENVIRONMENTAL PERFORMANCE ......................................... 5 - 33

A. Water Extraction

B. Waste Discharge

C. Energy Usage

D. Solid Wastes

E. Machinery maintenance workshop and fuel storage

II. ENVIRONMENTAL MANAGEMENT INITIATIVES ..................... 34 - 50

A. Buffer Zone Management

B. Conservation Area Management

C. Water Management Plan

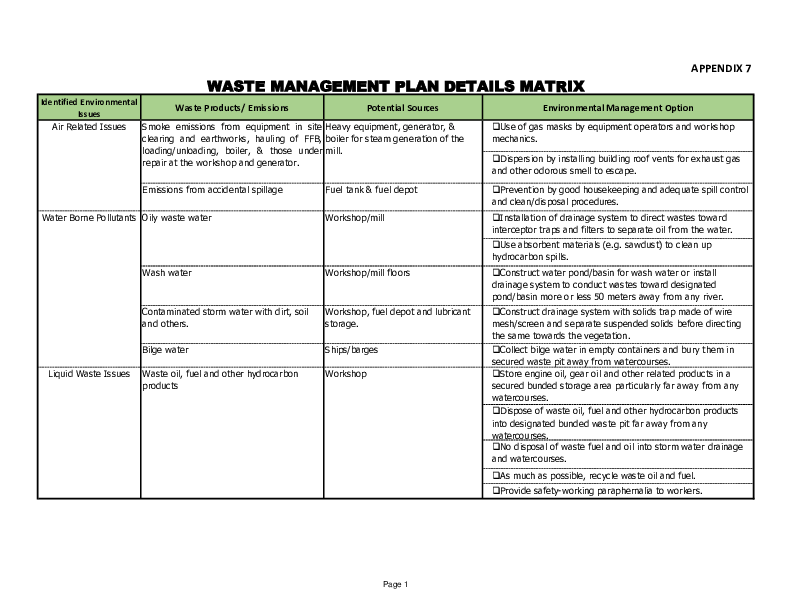

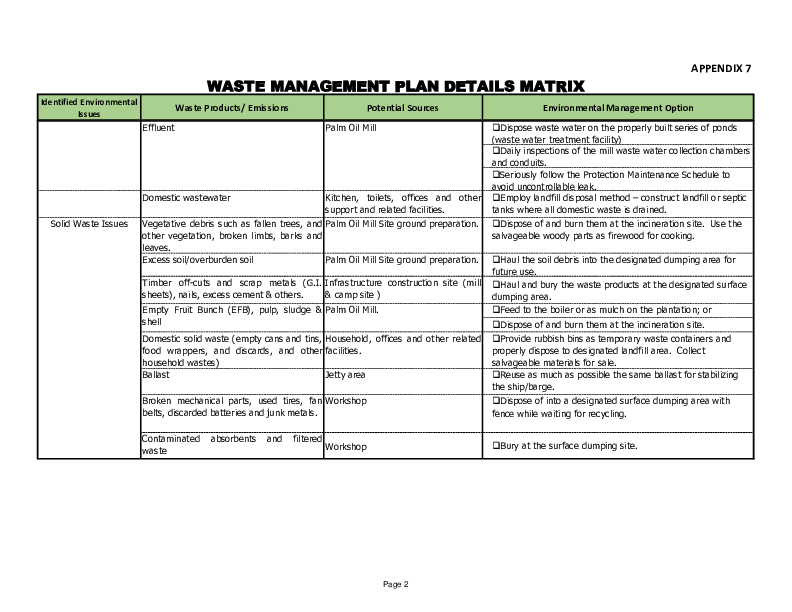

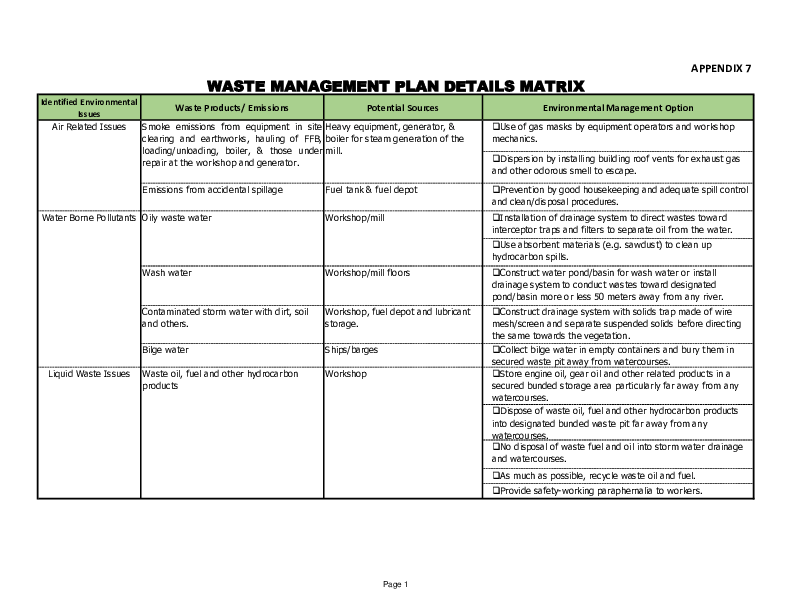

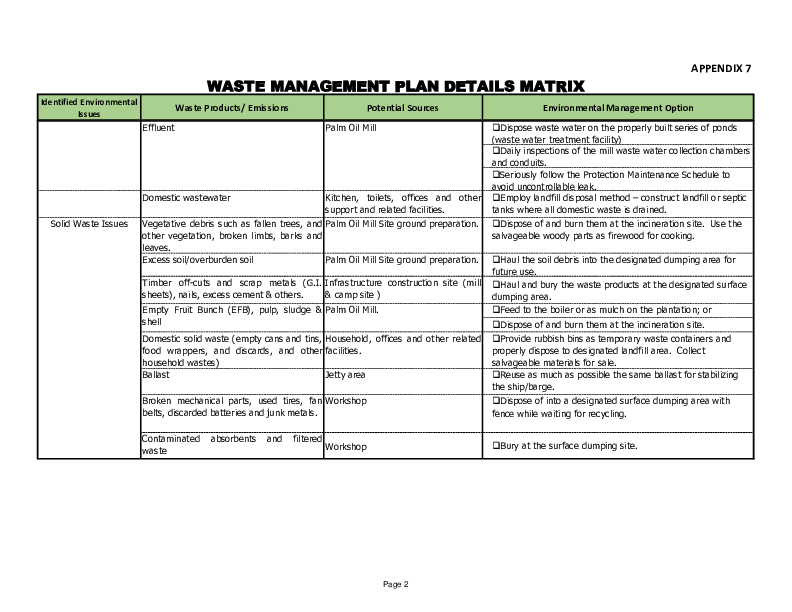

D. Waste Management Plan

E. Agrochemicals Management

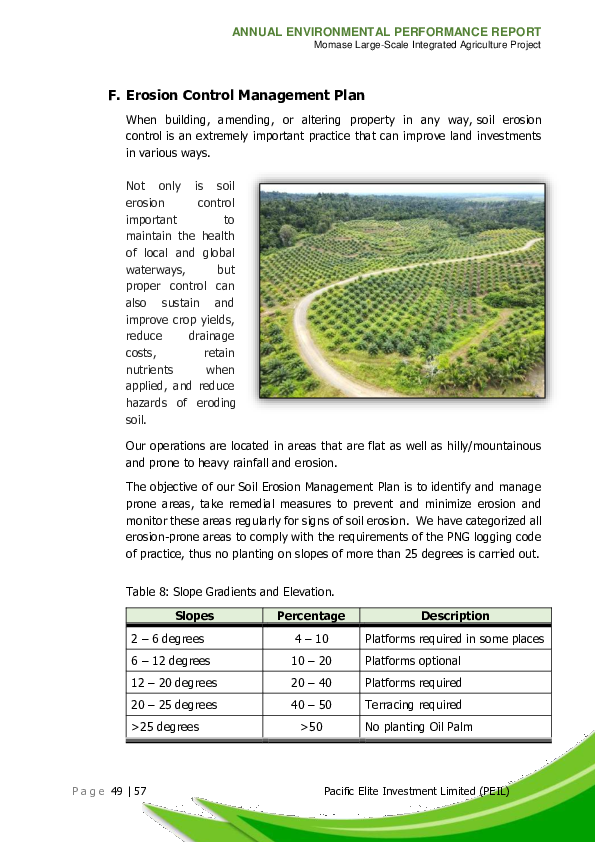

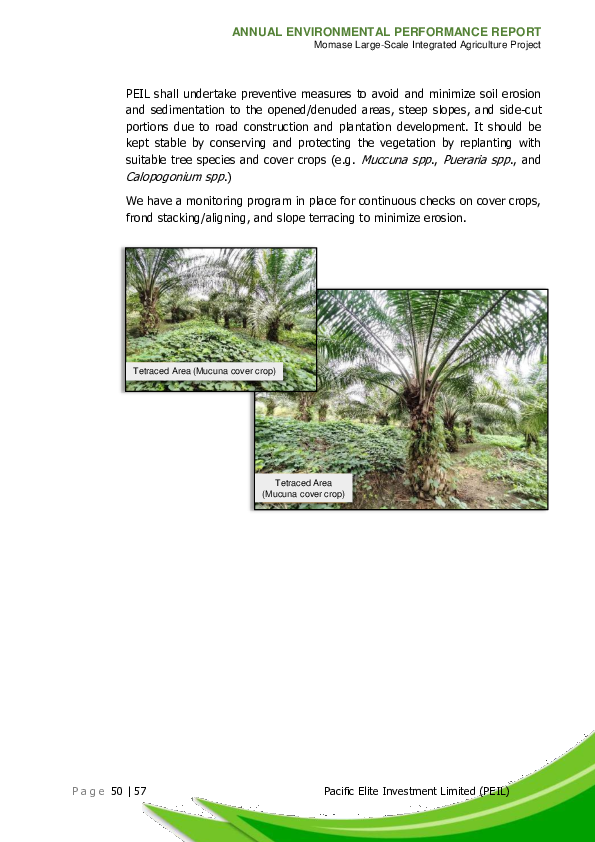

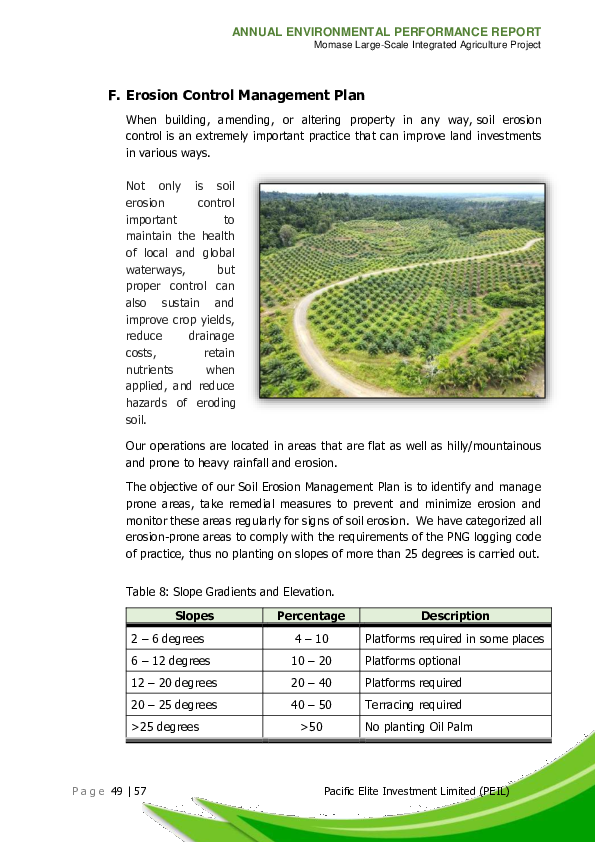

F. Erosion Control Management Plan

III. CONCLUSION .................................................................... 51

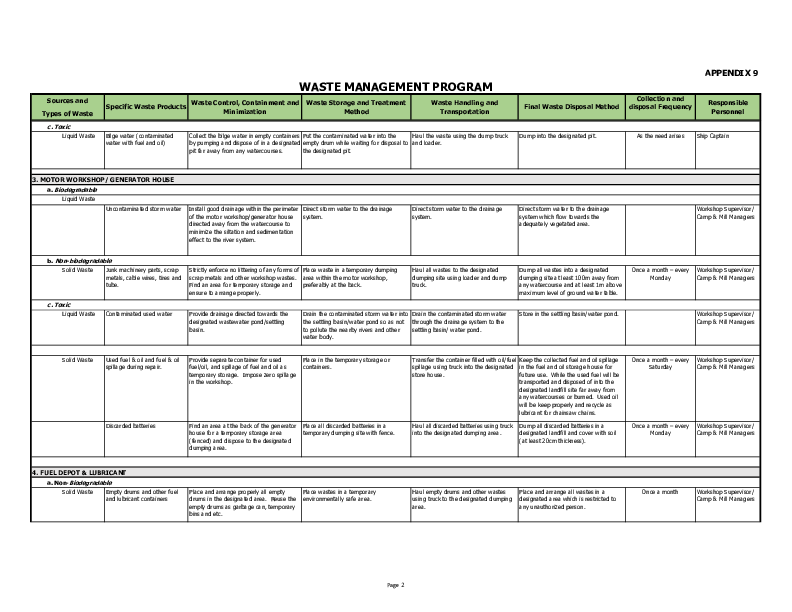

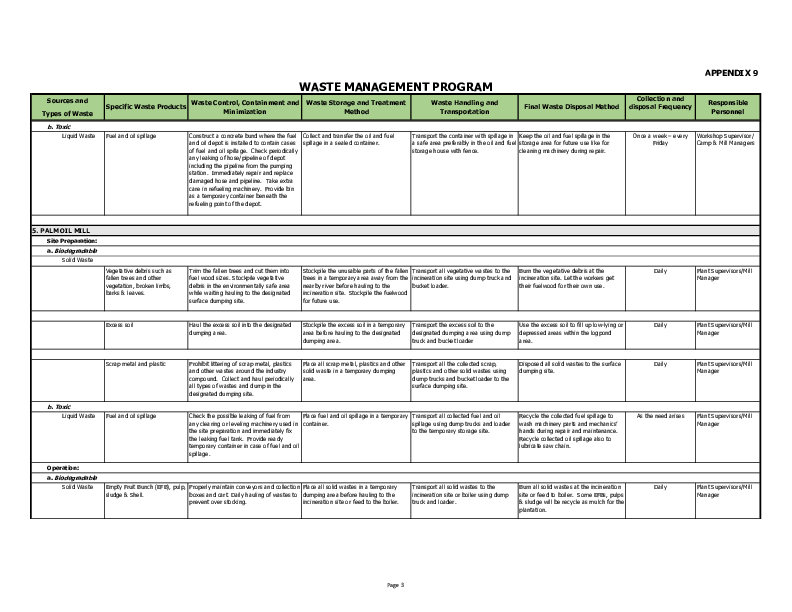

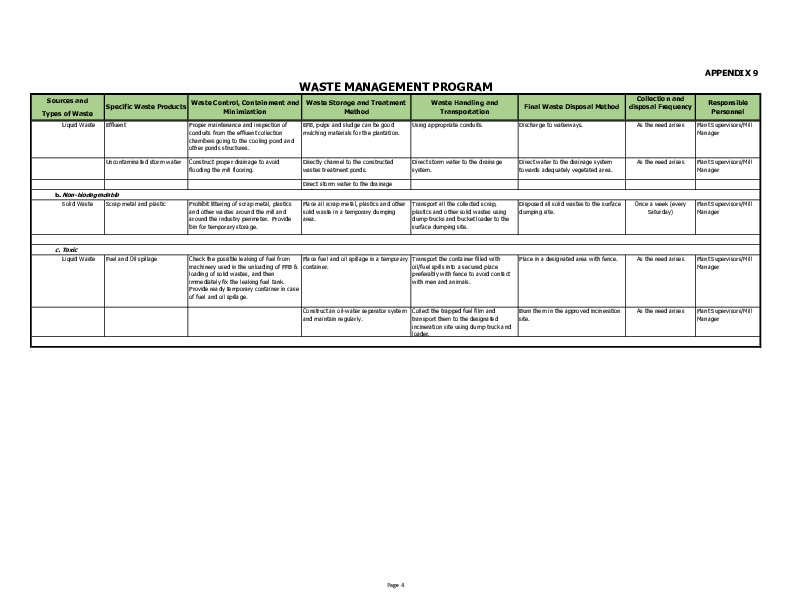

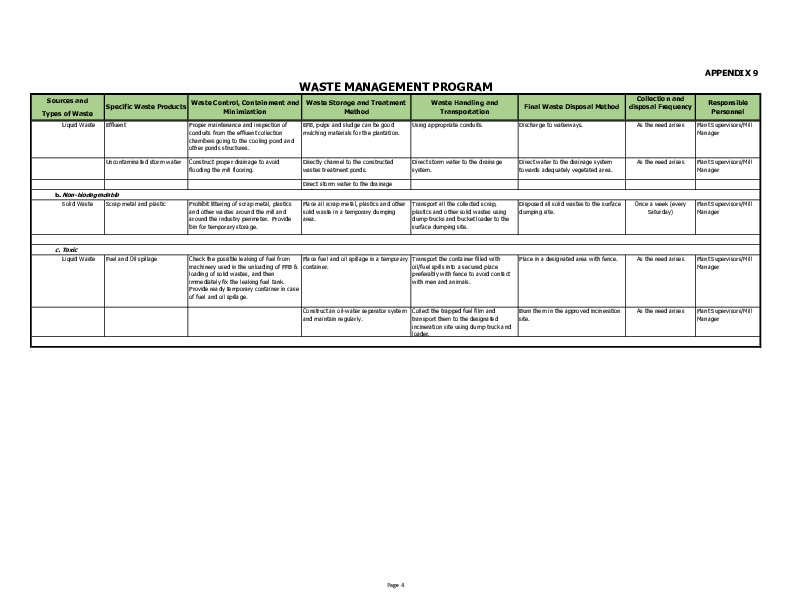

IV. WASTE MANAGEMENT PROGRAM ........................................... 51 - 56

A. Waste Management Program Component

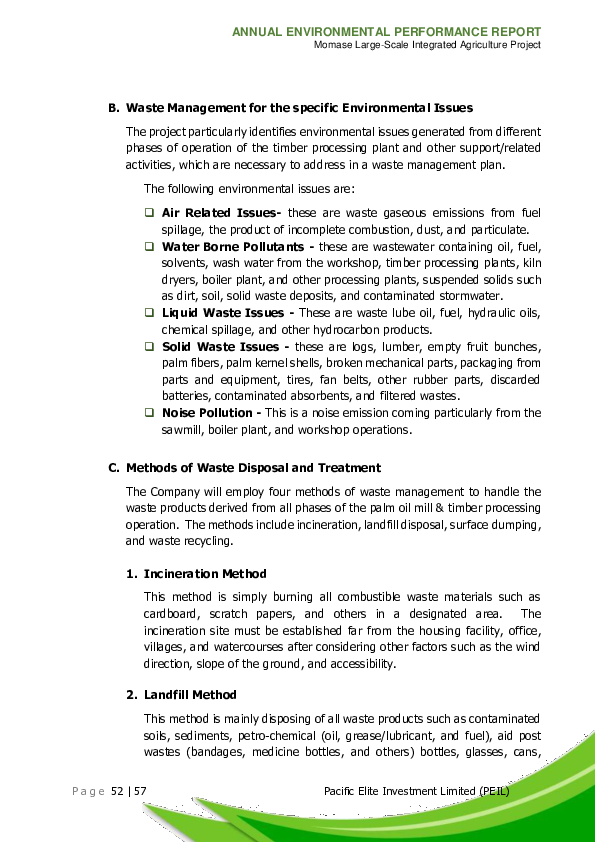

B. Waste Management for the specific Environmental Issues

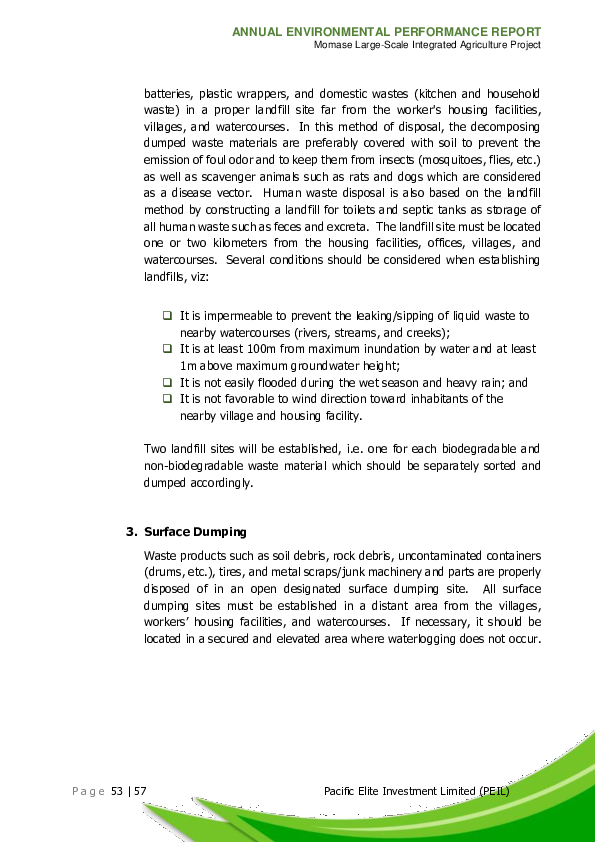

C. Methods of Waste Disposal and Treatment

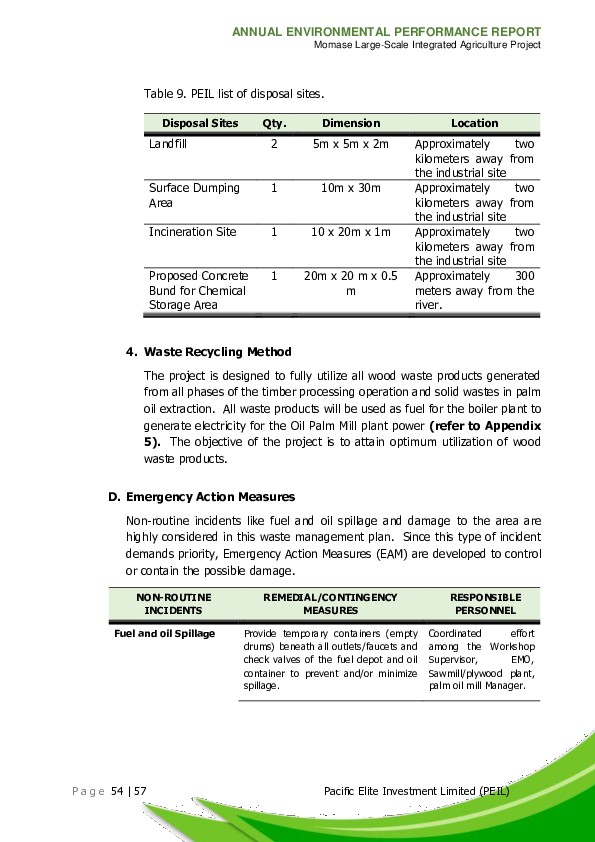

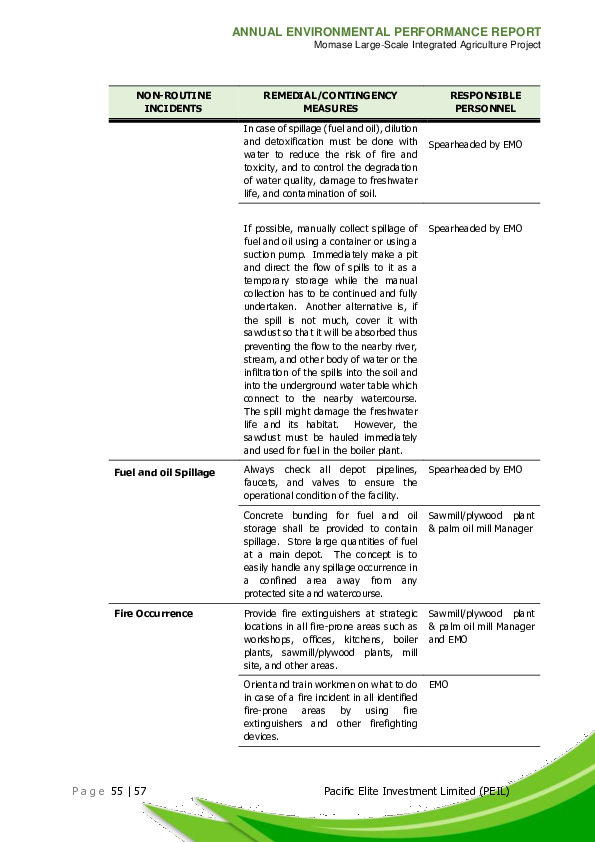

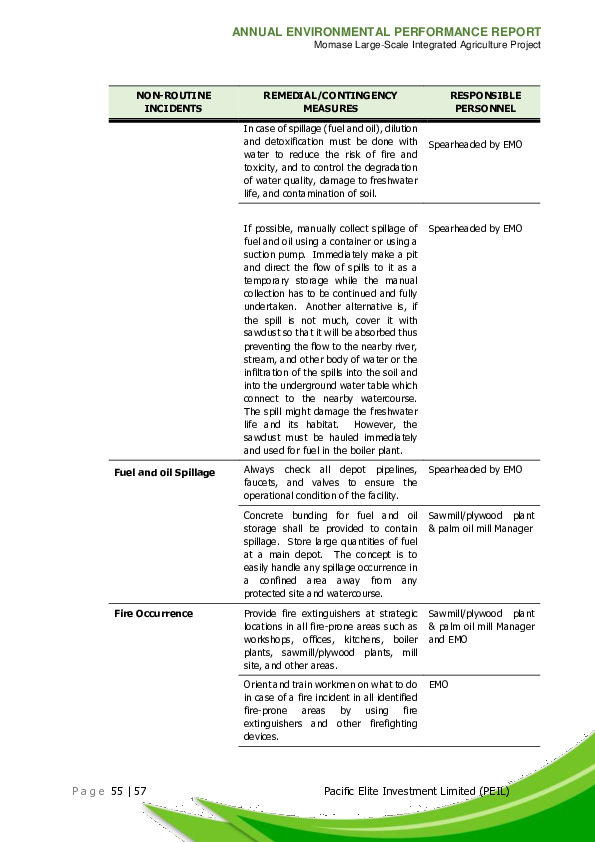

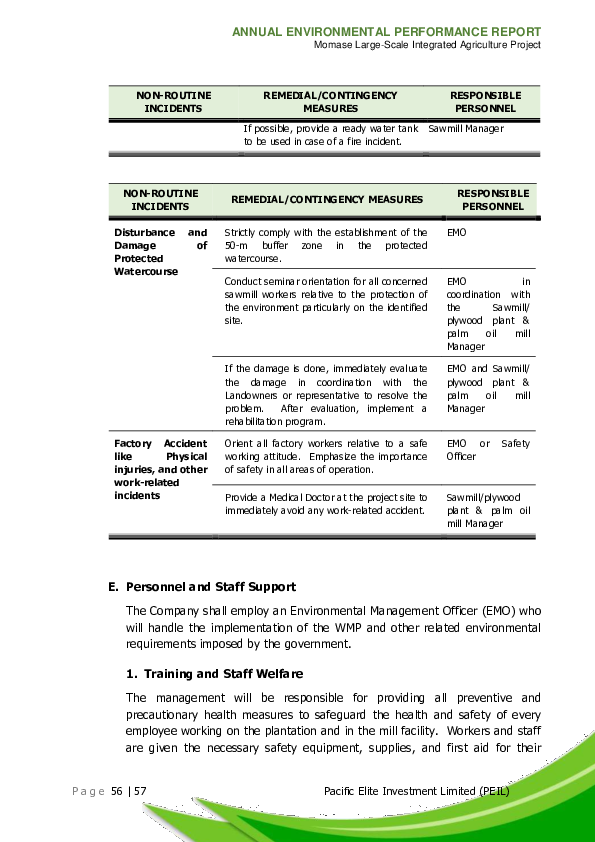

D. Emergency Action Measures

E. Personnel and Staff Support

V. COMMITMENTS ...................................................................... 57

�

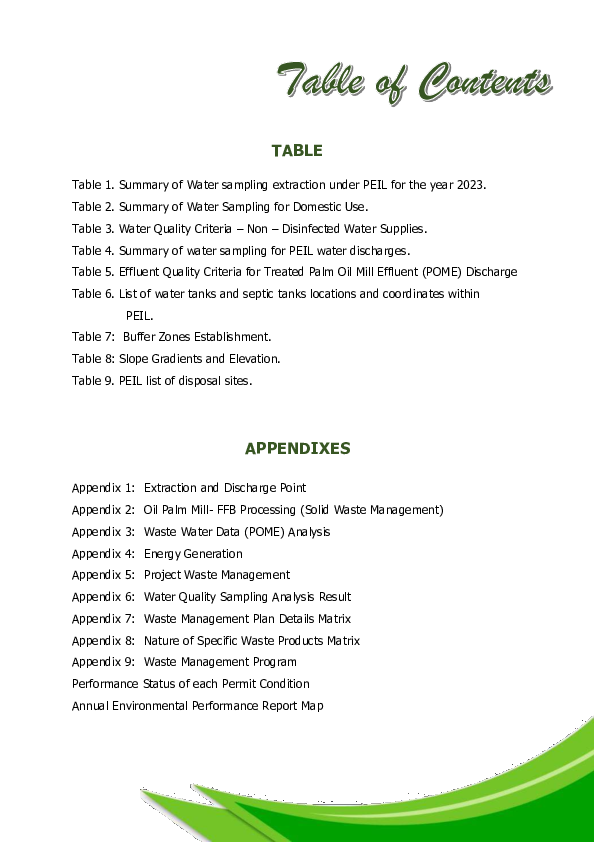

TABLE

Table 1. Summary of Water sampling extraction under PEIL for the year 2023.

Table 2. Summary of Water Sampling for Domestic Use.

Table 3. Water Quality Criteria – Non – Disinfected Water Supplies.

Table 4. Summary of water sampling for PEIL water discharges.

Table 5. Effluent Quality Criteria for Treated Palm Oil Mill Effluent (POME) Discharge

Table 6. List of water tanks and septic tanks locations and coordinates within

PEIL.

Table 7: Buffer Zones Establishment.

Table 8: Slope Gradients and Elevation.

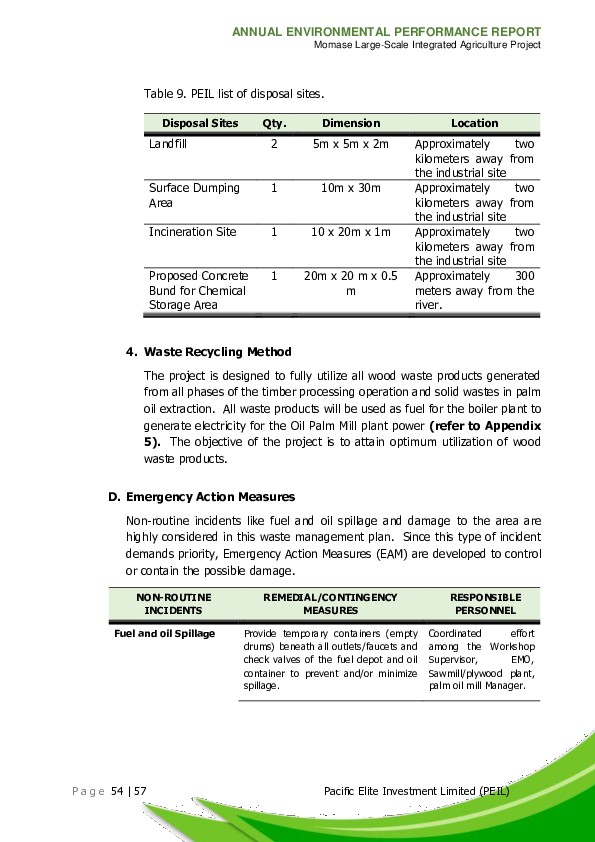

Table 9. PEIL list of disposal sites.

APPENDIXES

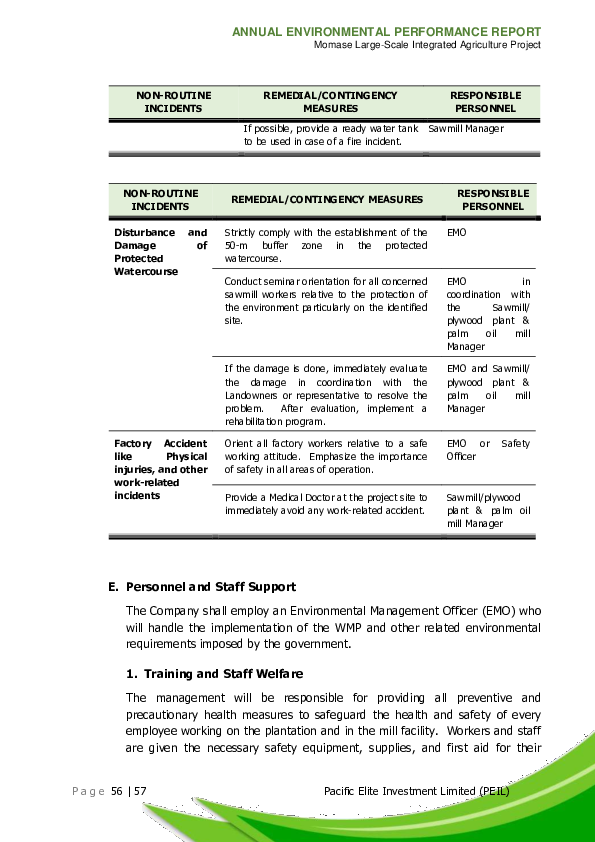

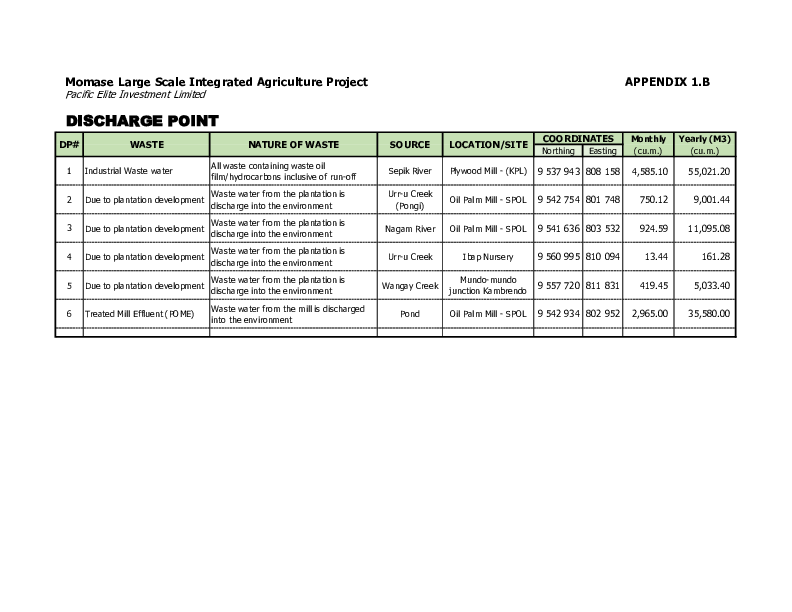

Appendix 1: Extraction and Discharge Point

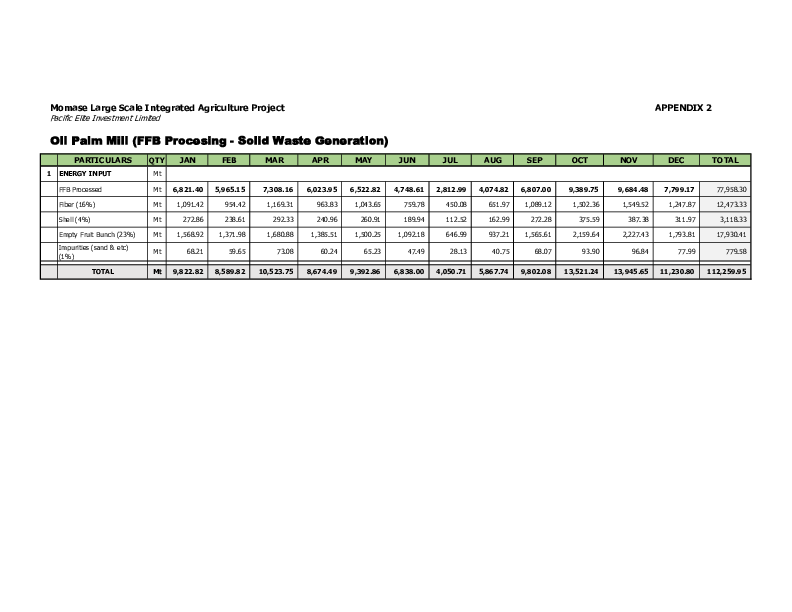

Appendix 2: Oil Palm Mill- FFB Processing (Solid Waste Management)

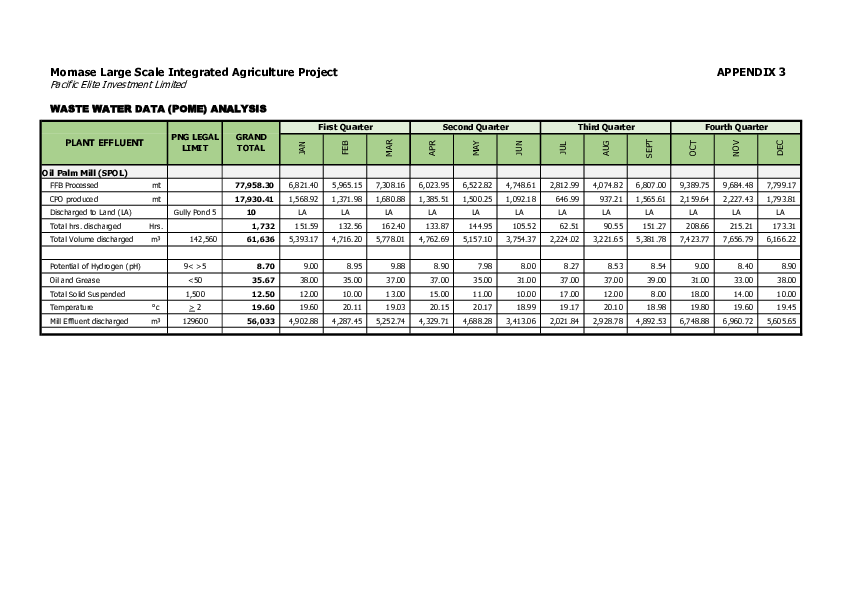

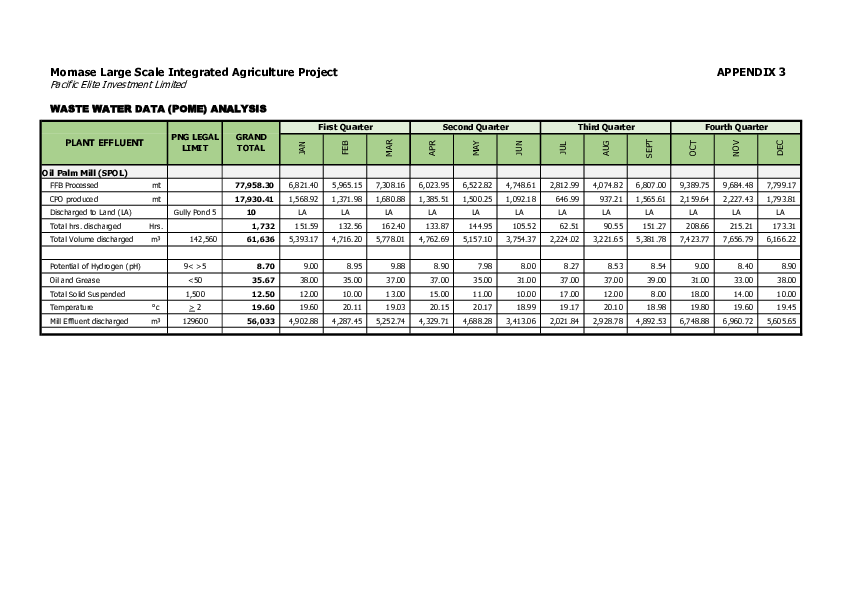

Appendix 3: Waste Water Data (POME) Analysis

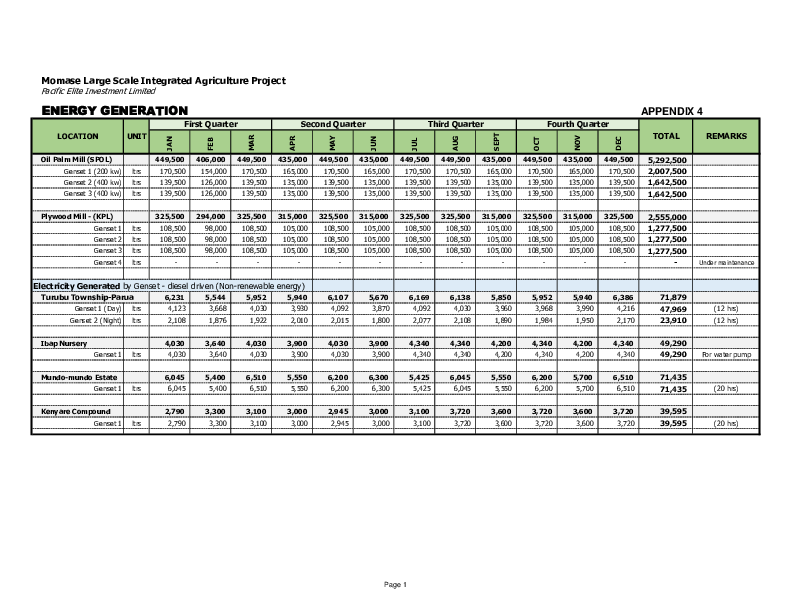

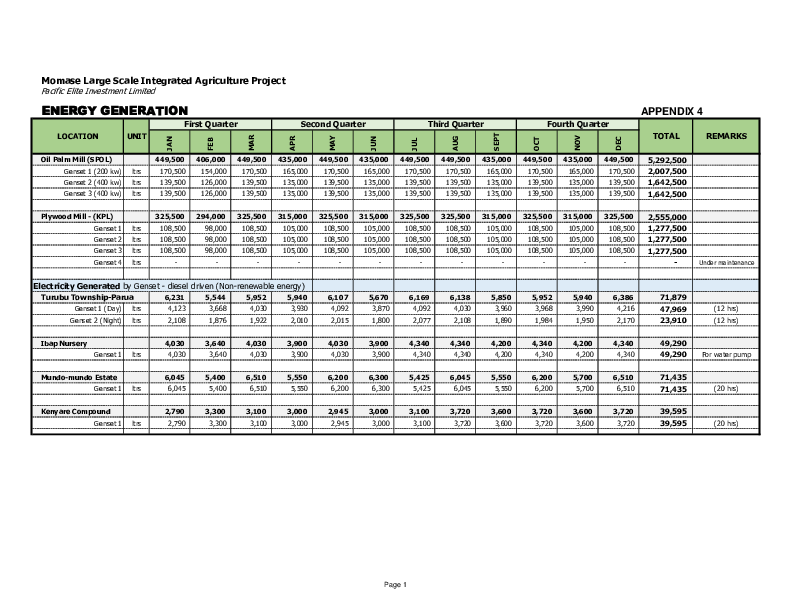

Appendix 4: Energy Generation

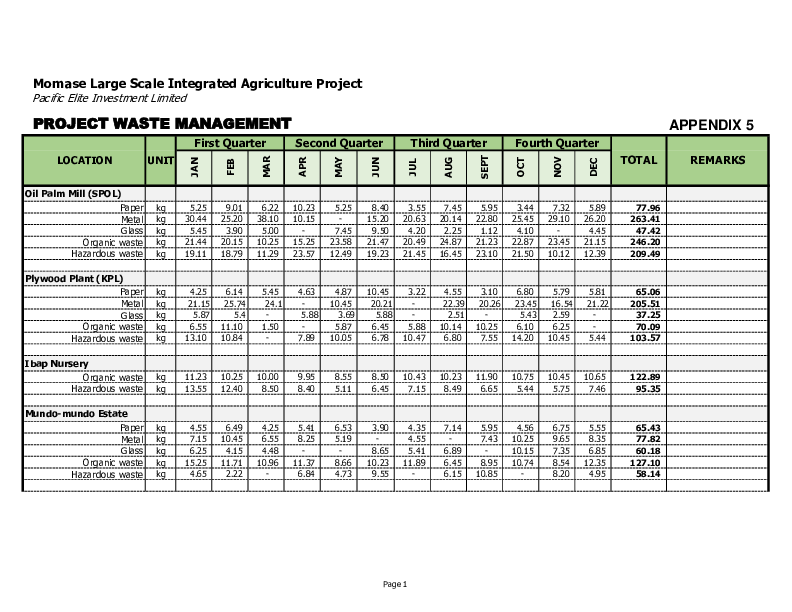

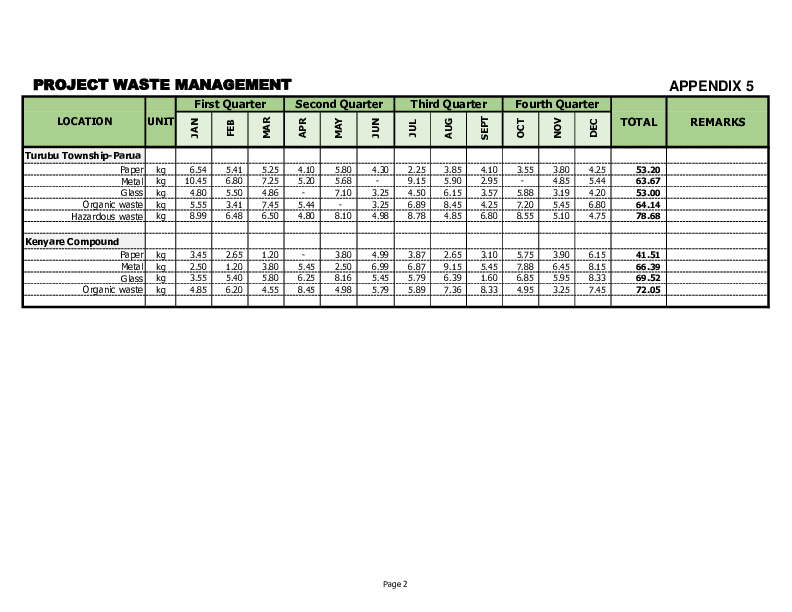

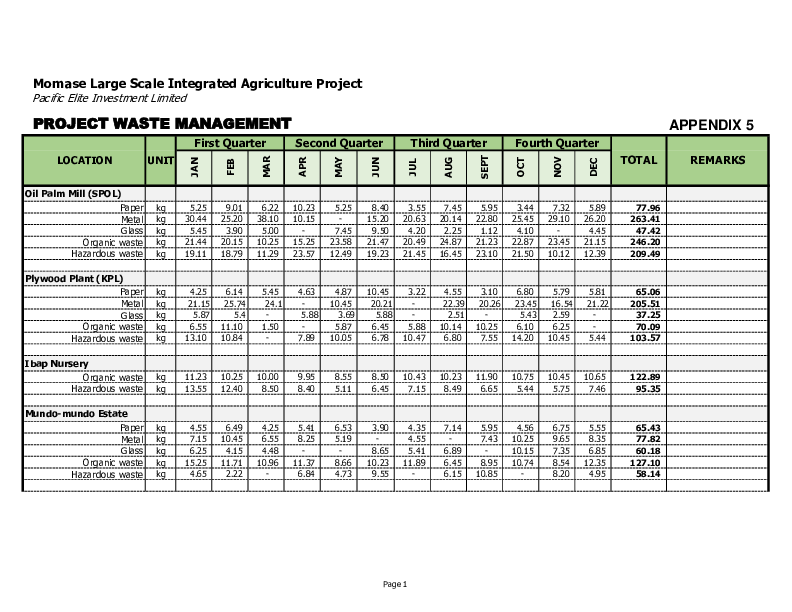

Appendix 5: Project Waste Management

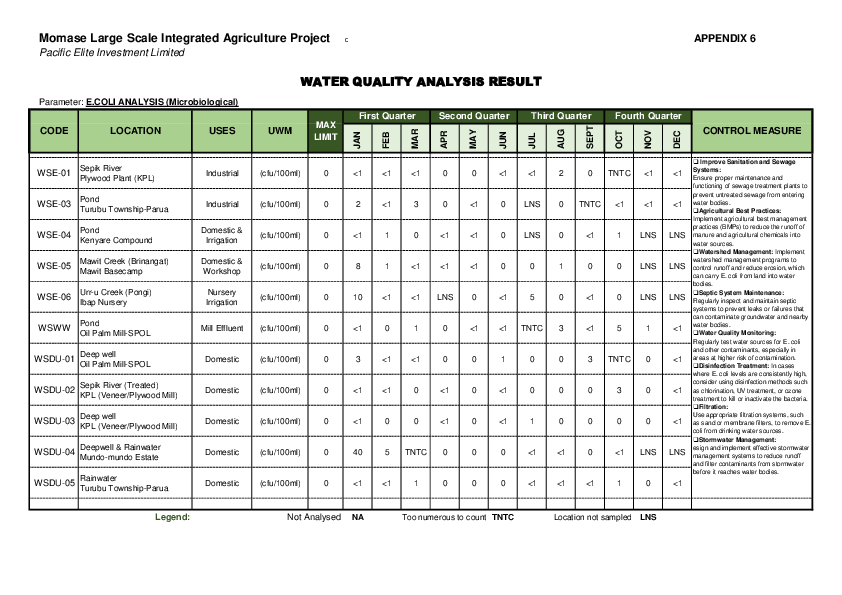

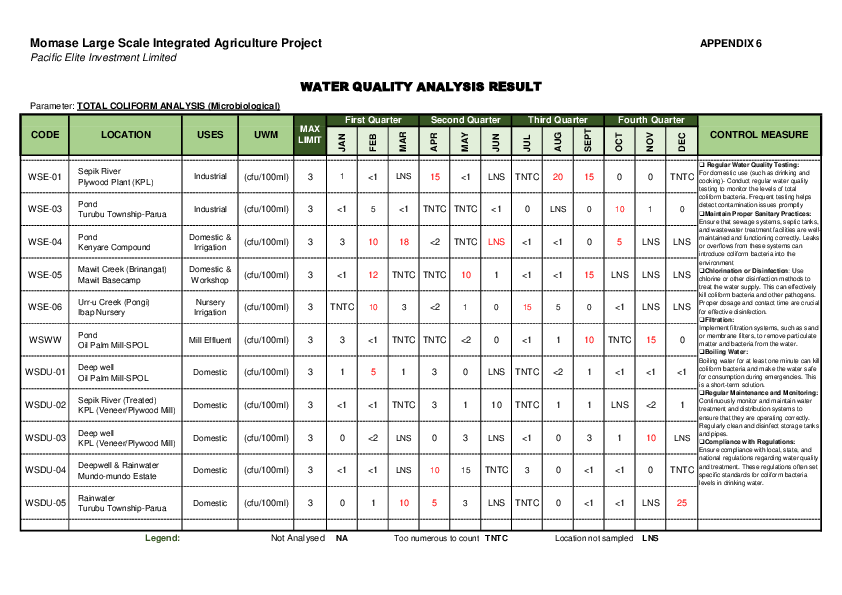

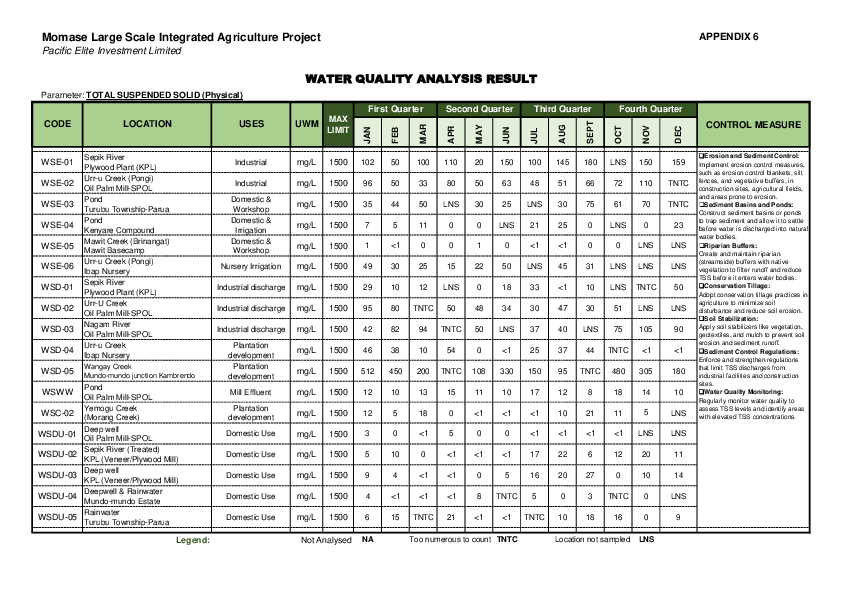

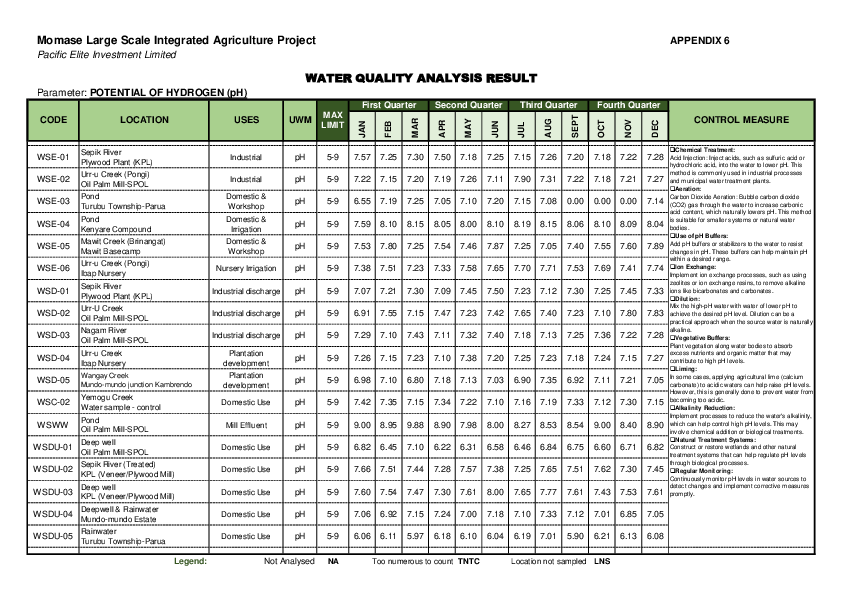

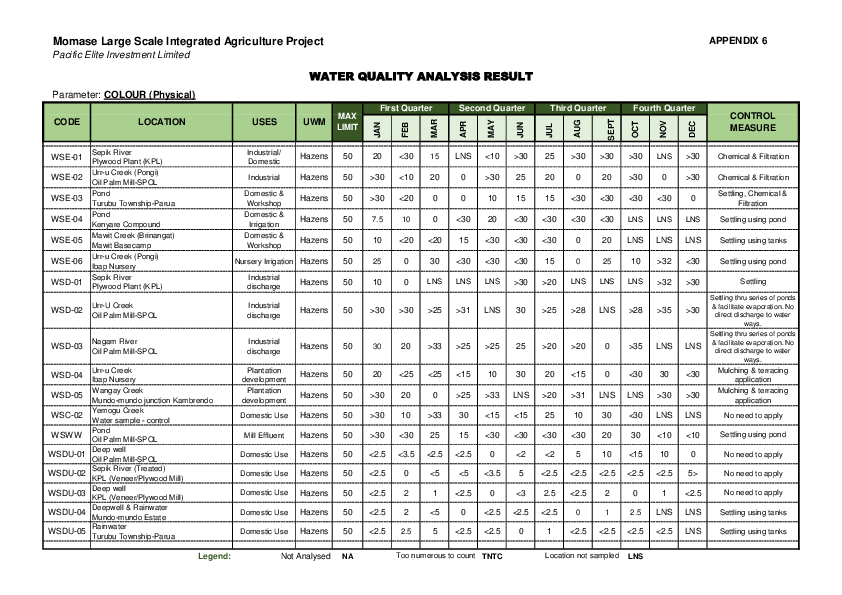

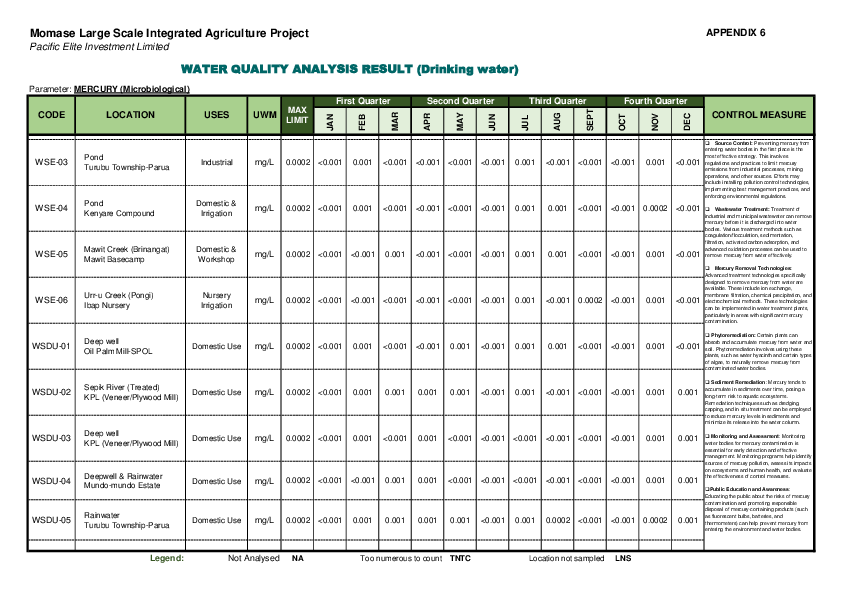

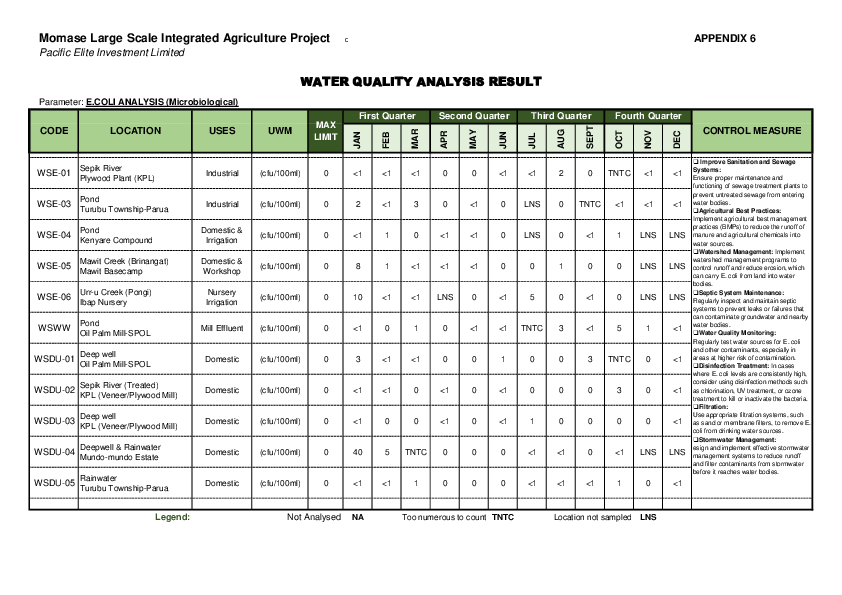

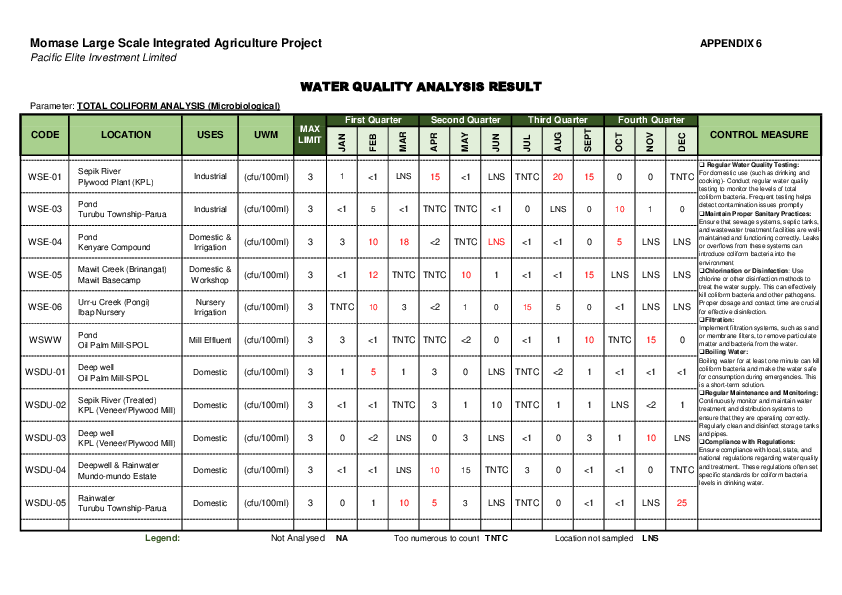

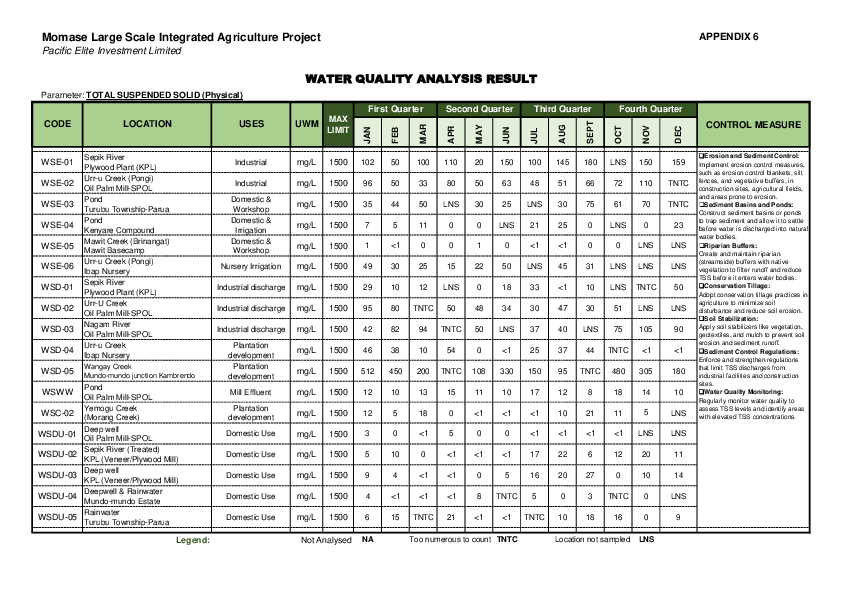

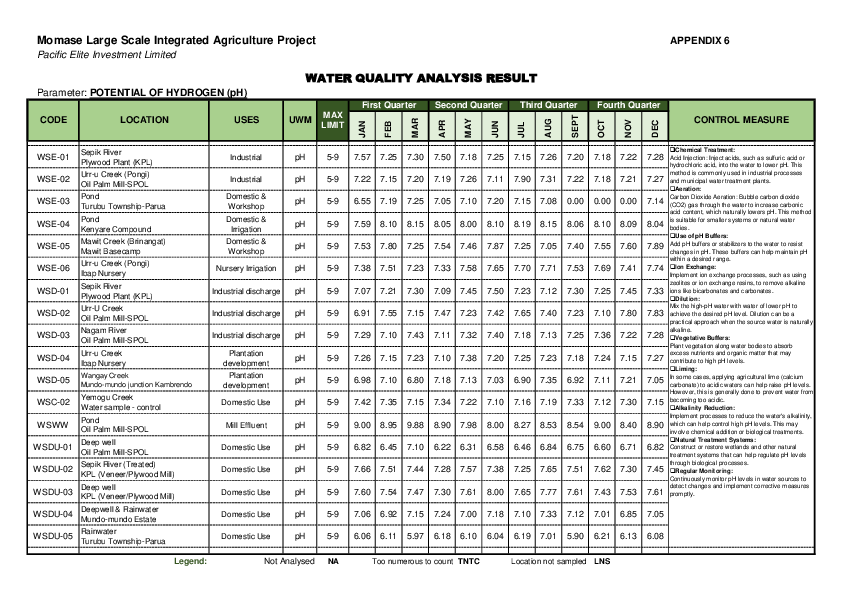

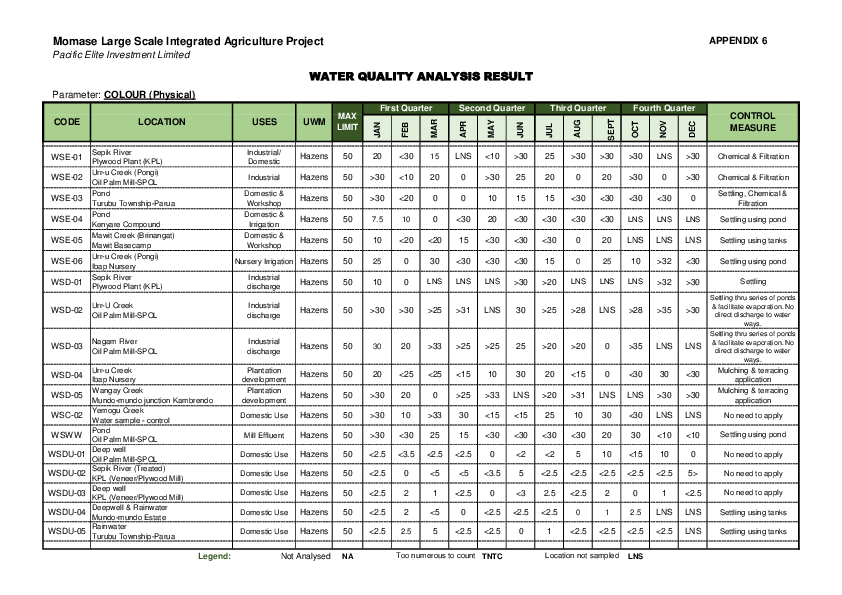

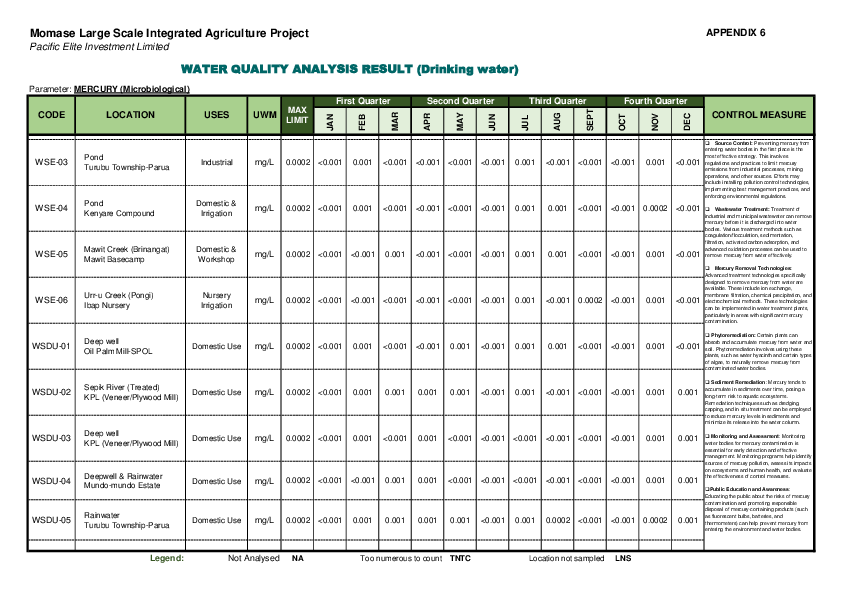

Appendix 6: Water Quality Sampling Analysis Result

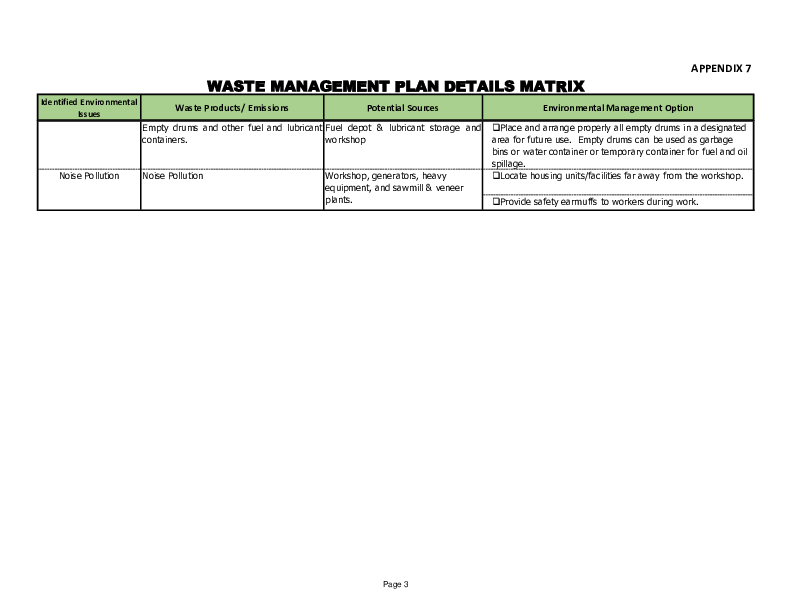

Appendix 7: Waste Management Plan Details Matrix

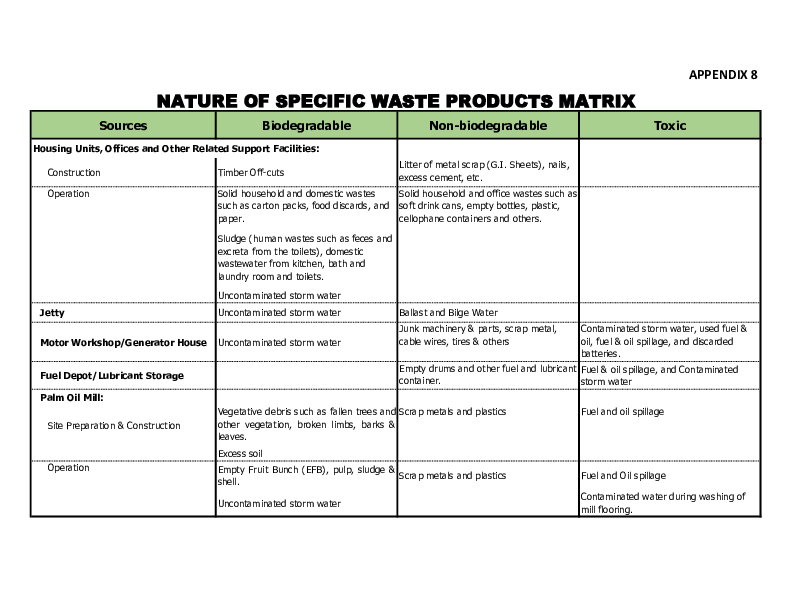

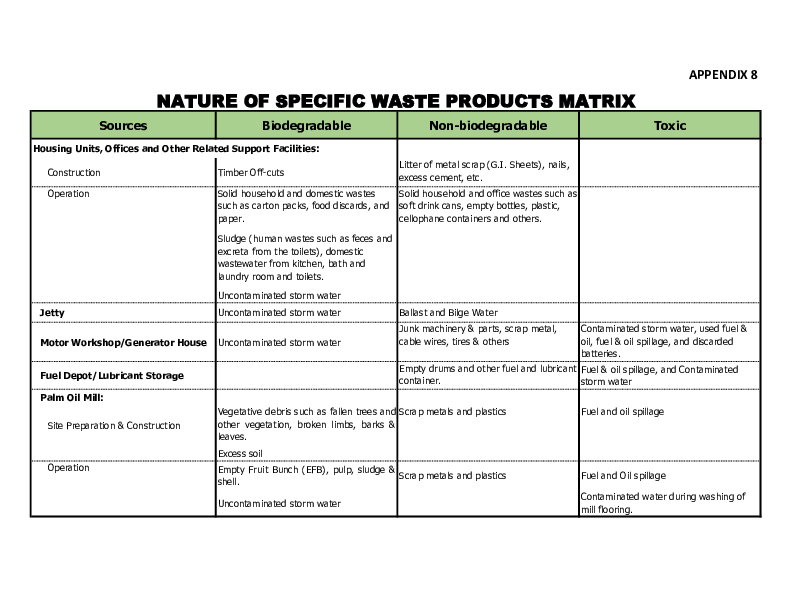

Appendix 8: Nature of Specific Waste Products Matrix

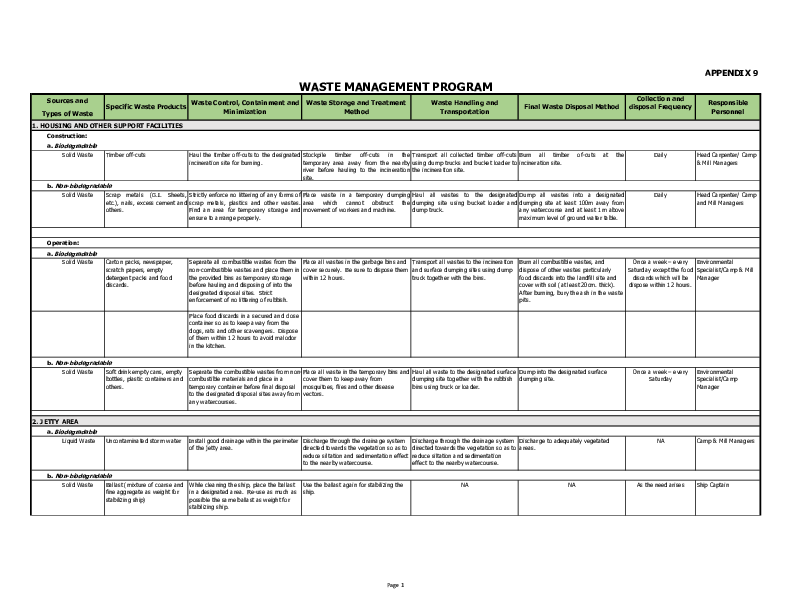

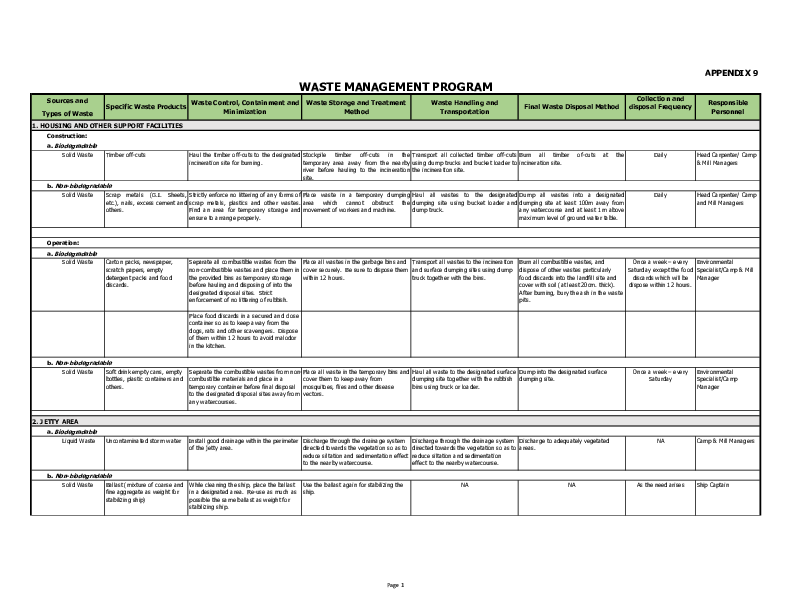

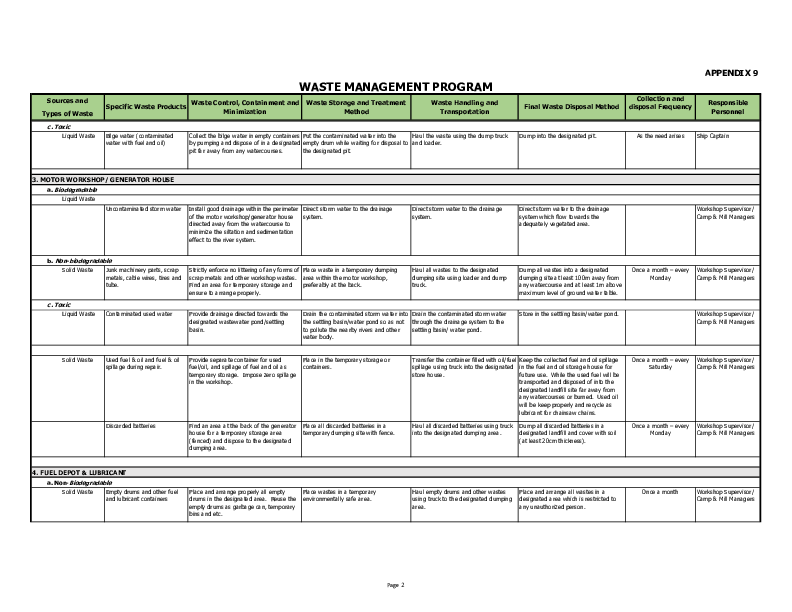

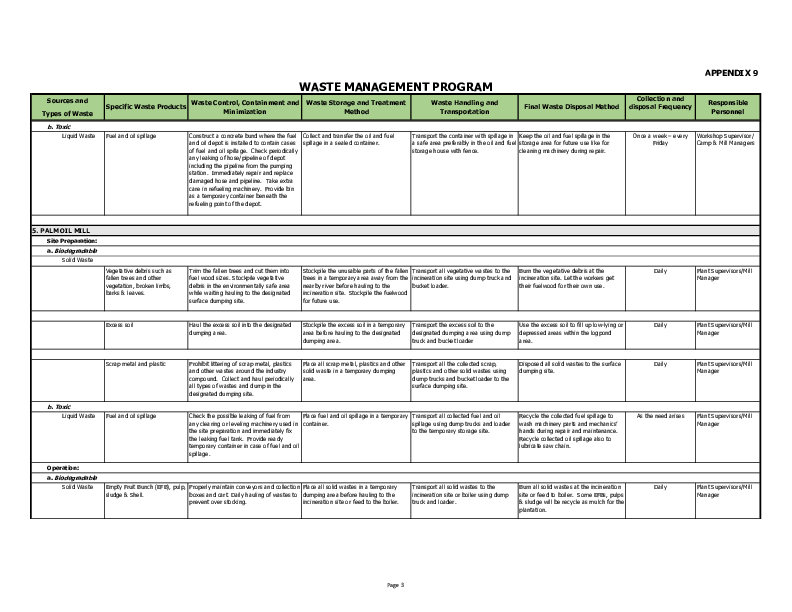

Appendix 9: Waste Management Program

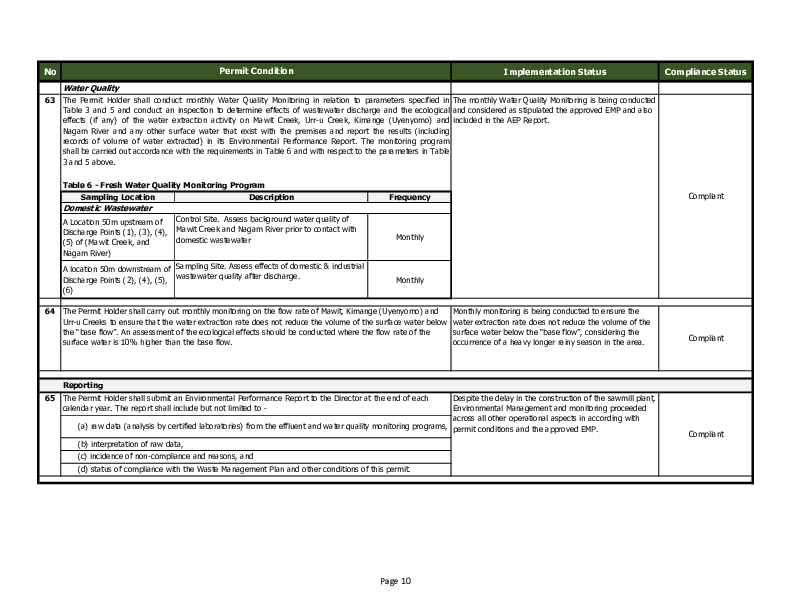

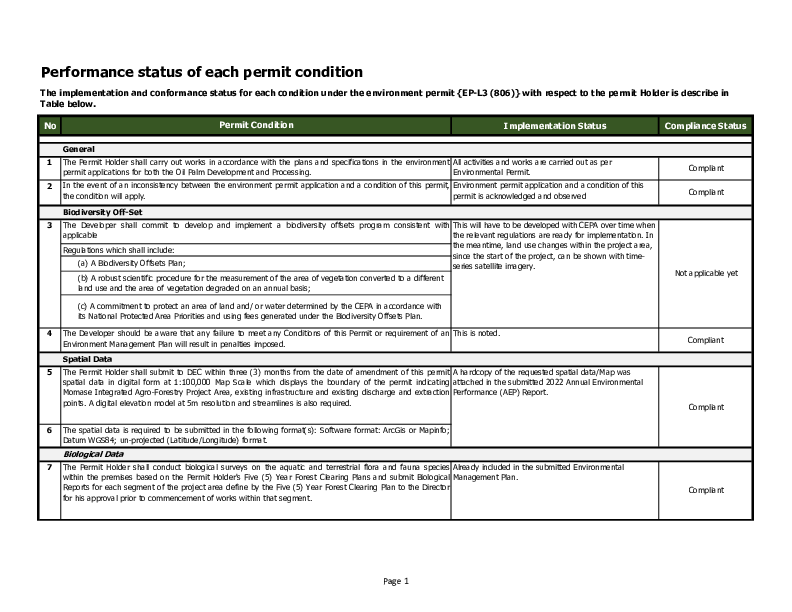

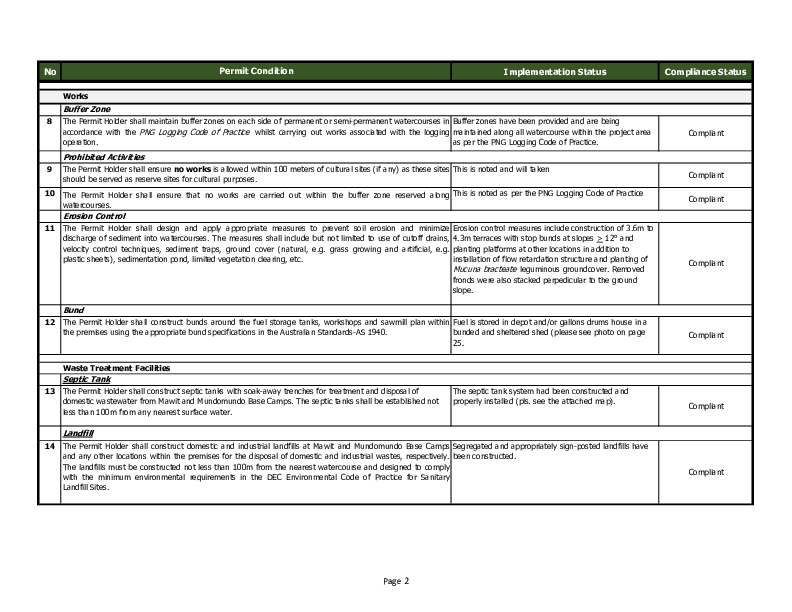

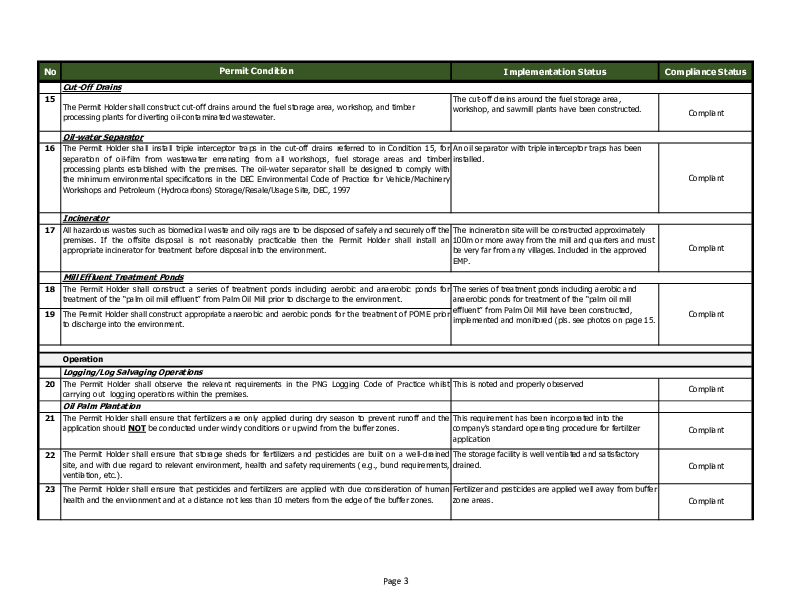

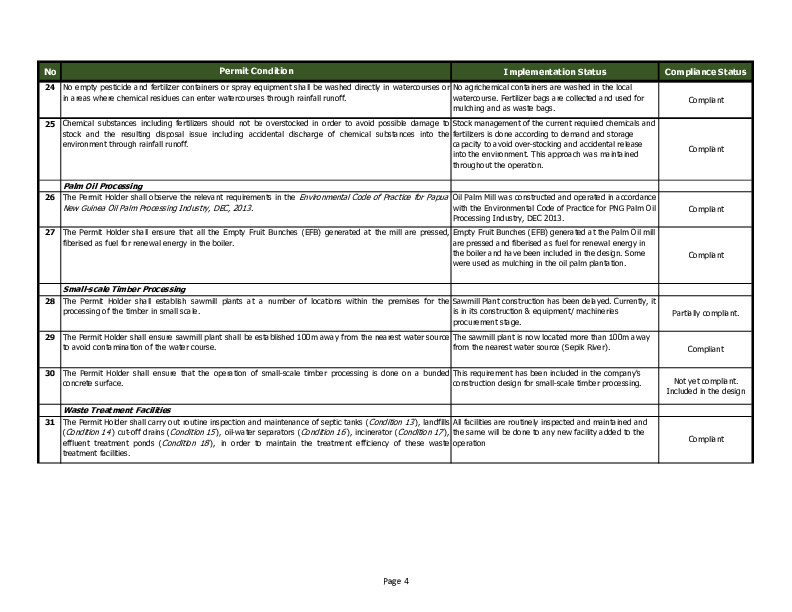

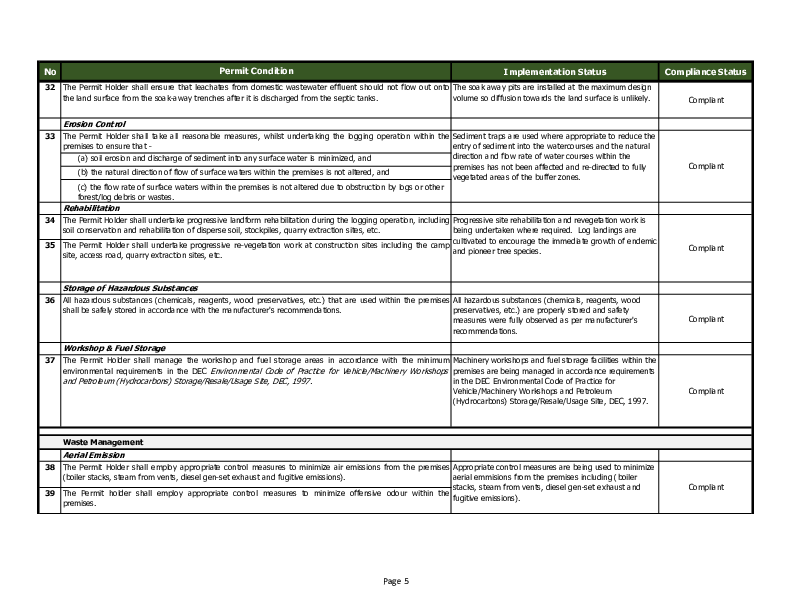

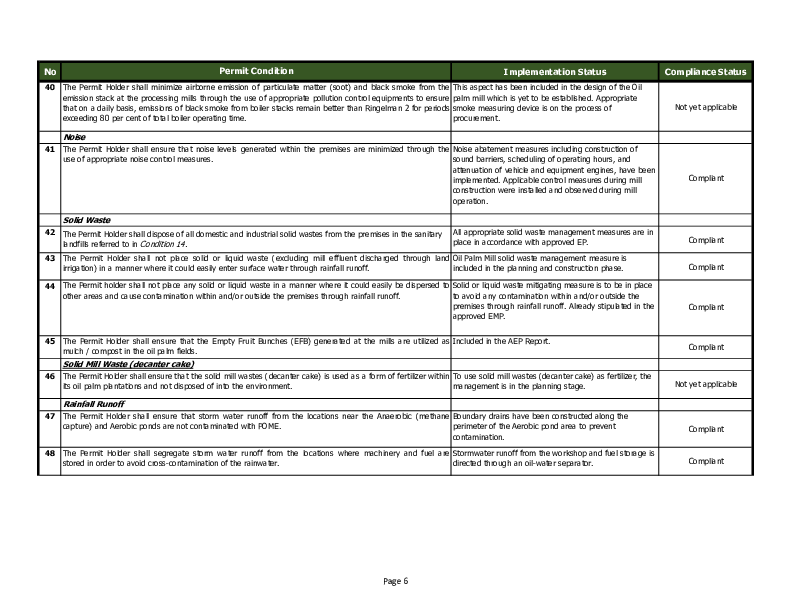

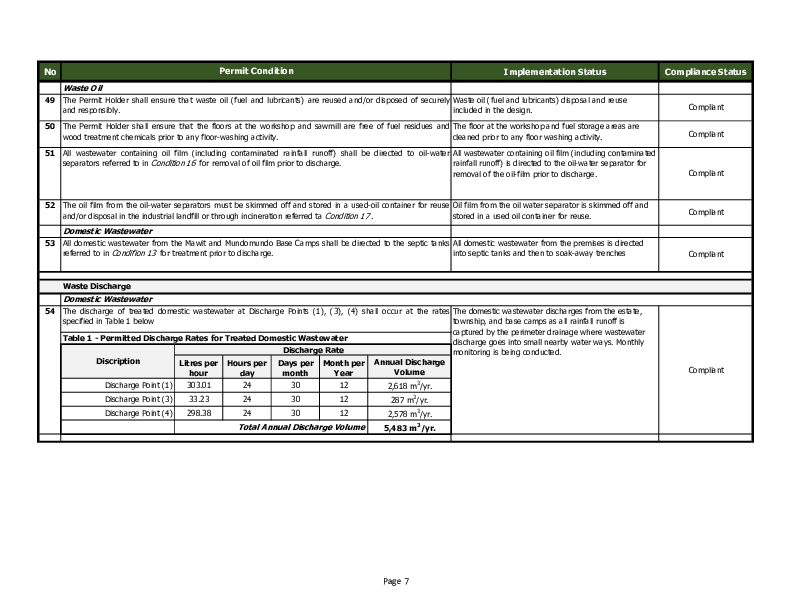

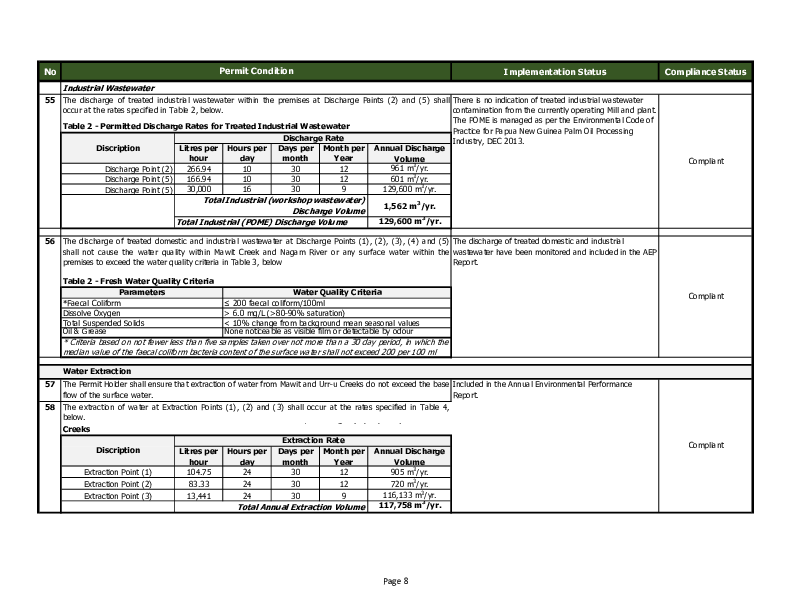

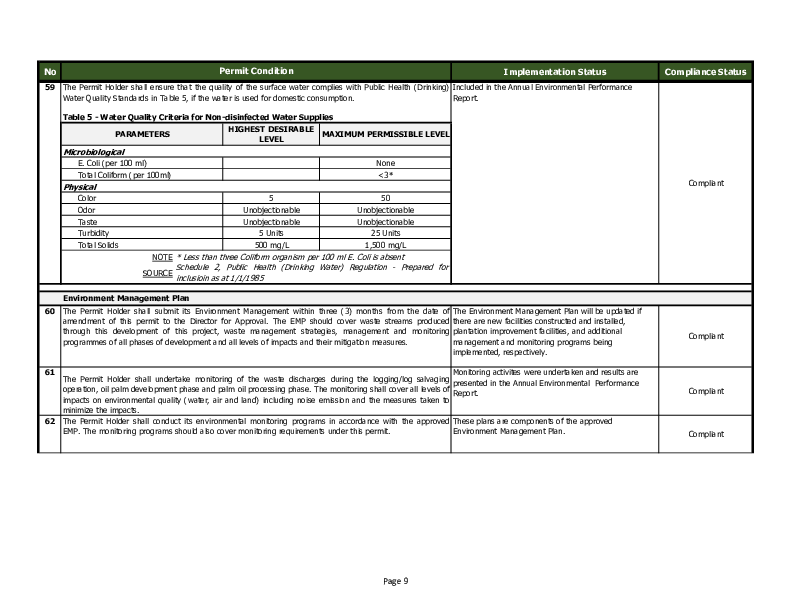

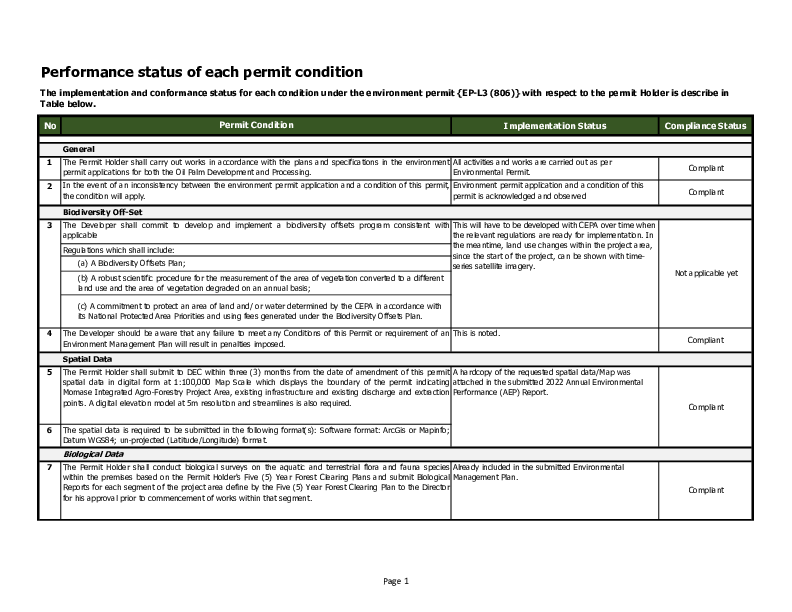

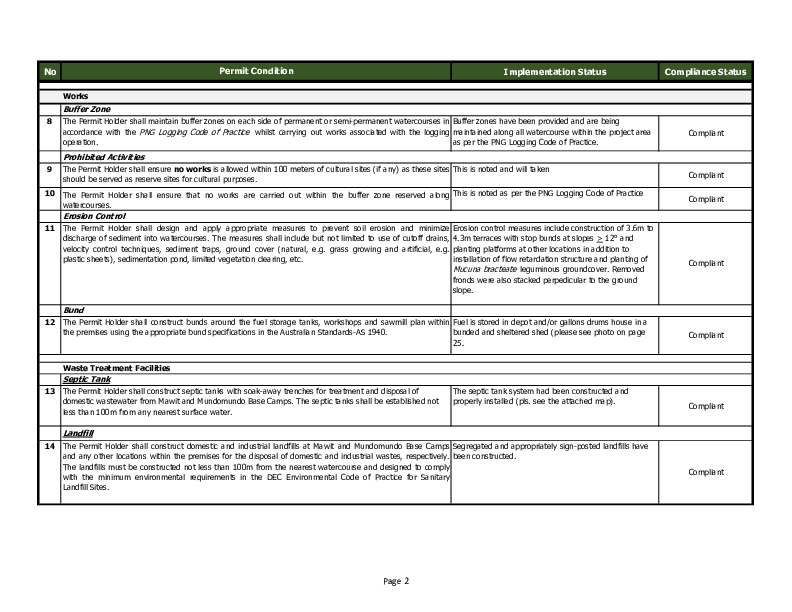

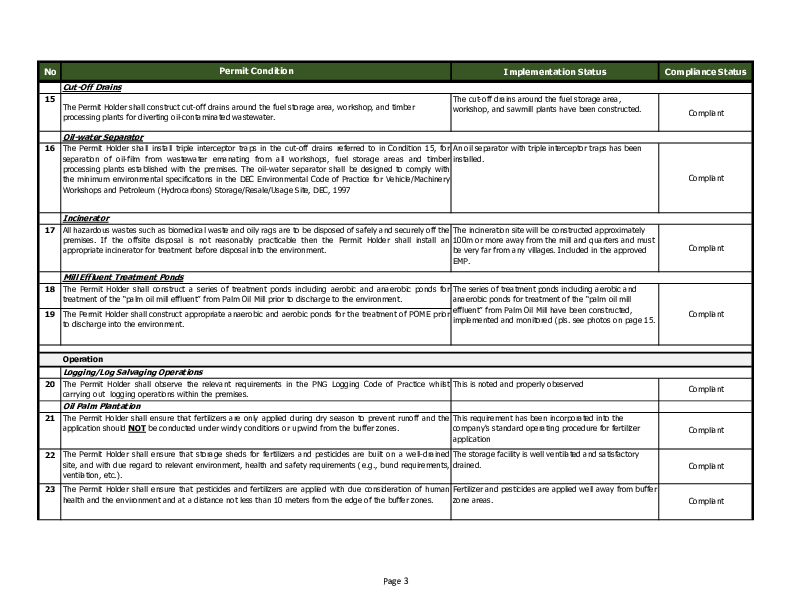

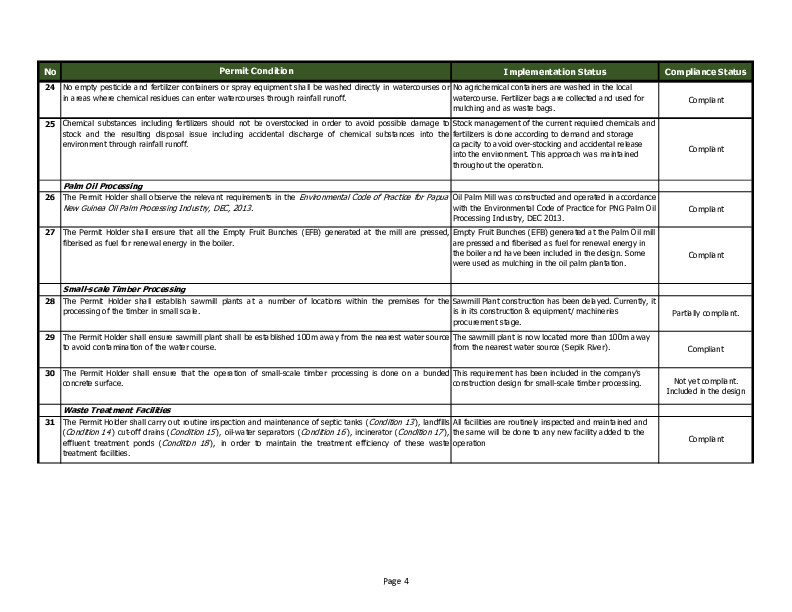

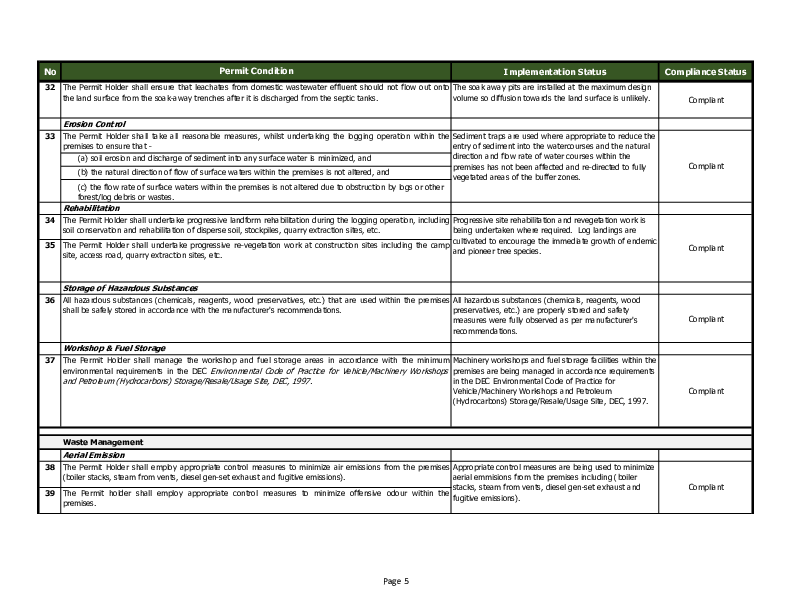

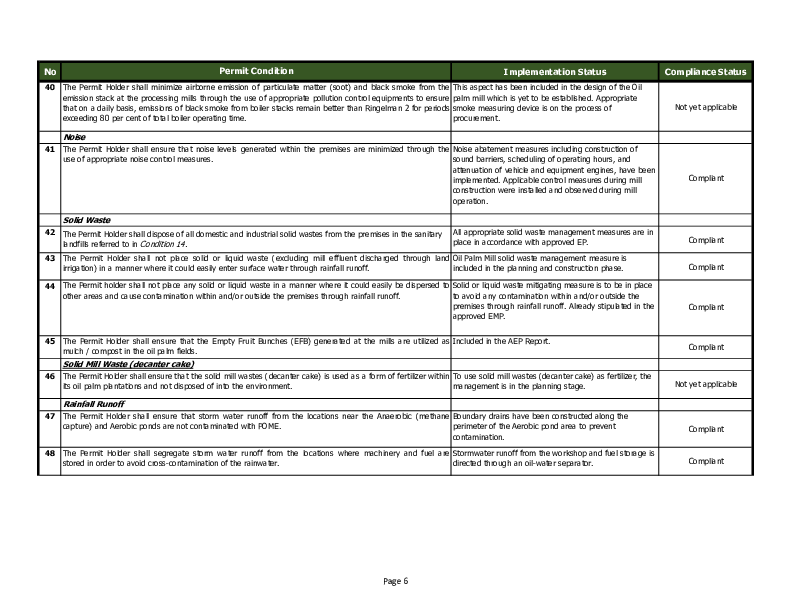

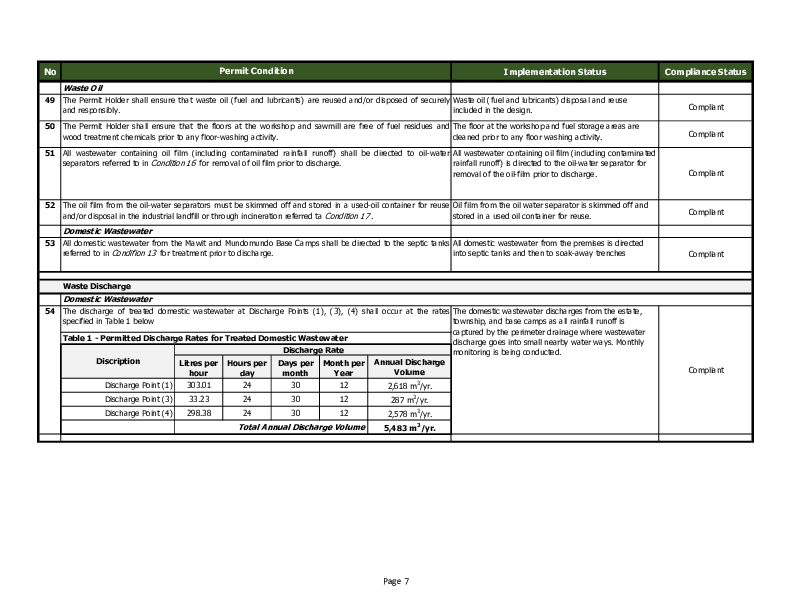

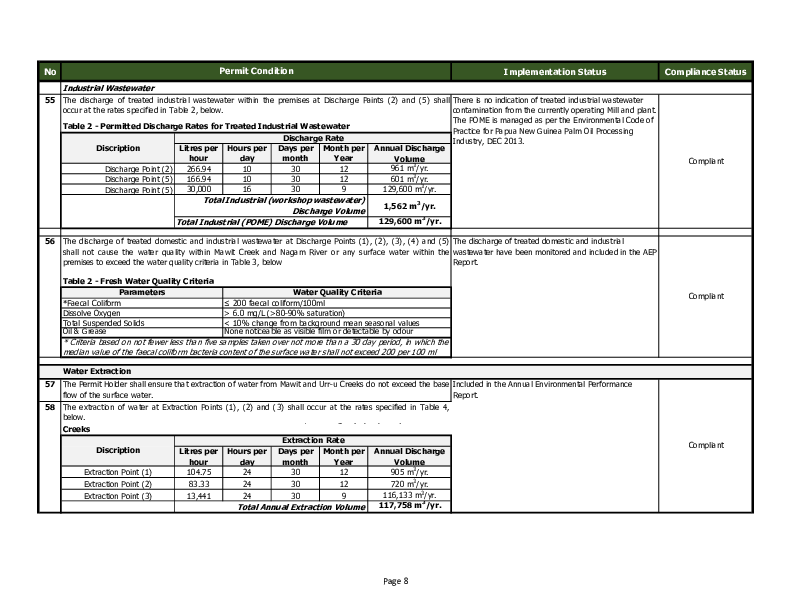

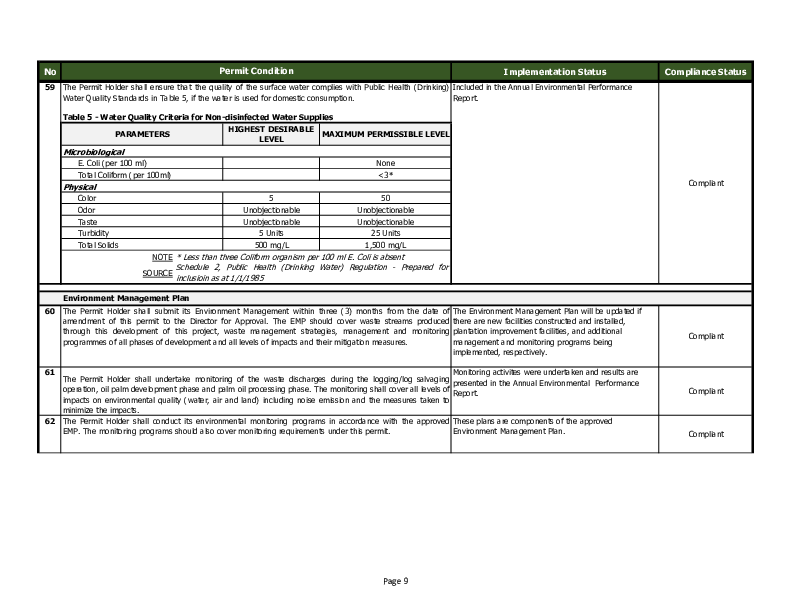

Performance Status of each Permit Condition

Annual Environmental Performance Report Map

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

PROJECT FACT SHEET

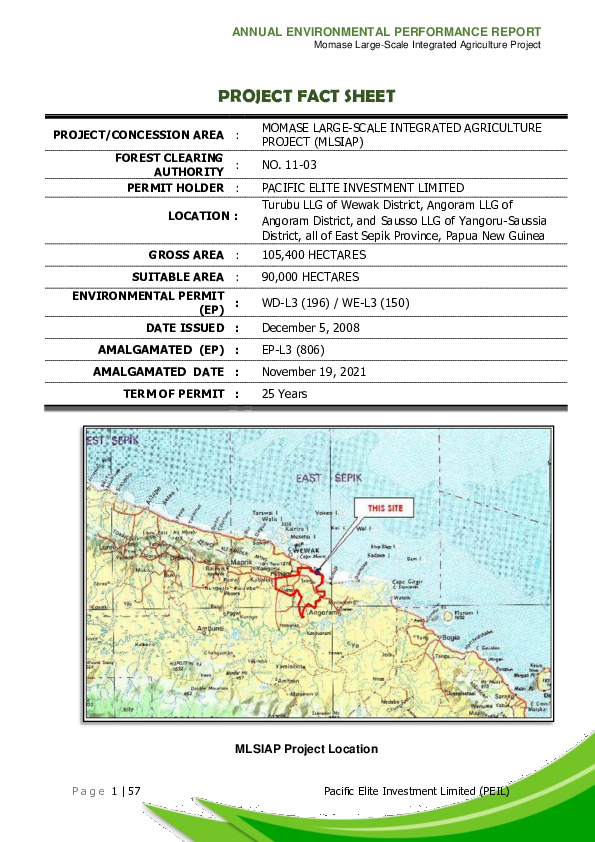

MOMASE LARGE-SCALE INTEGRATED AGRICULTURE

PROJECT/CONCESSION AREA :

PROJECT (MLSIAP)

FOREST CLEARING

: NO. 11-03

AUTHORITY

PERMIT HOLDER : PACIFIC ELITE INVESTMENT LIMITED

Turubu LLG of Wewak District, Angoram LLG of

LOCATION : Angoram District, and Sausso LLG of Yangoru-Saussia

District, all of East Sepik Province, Papua New Guinea

GROSS AREA : 105,400 HECTARES

SUITABLE AREA : 90,000 HECTARES

ENVIRONMENTAL PERMIT

: WD-L3 (196) / WE-L3 (150)

(EP)

DATE ISSUED : December 5, 2008

AMALGAMATED (EP) : EP-L3 (806)

AMALGAMATED DATE : November 19, 2021

TERM OF PERMIT : 25 Years

MLSIAP Project Location

P a g e 1 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

INTRODUCTION

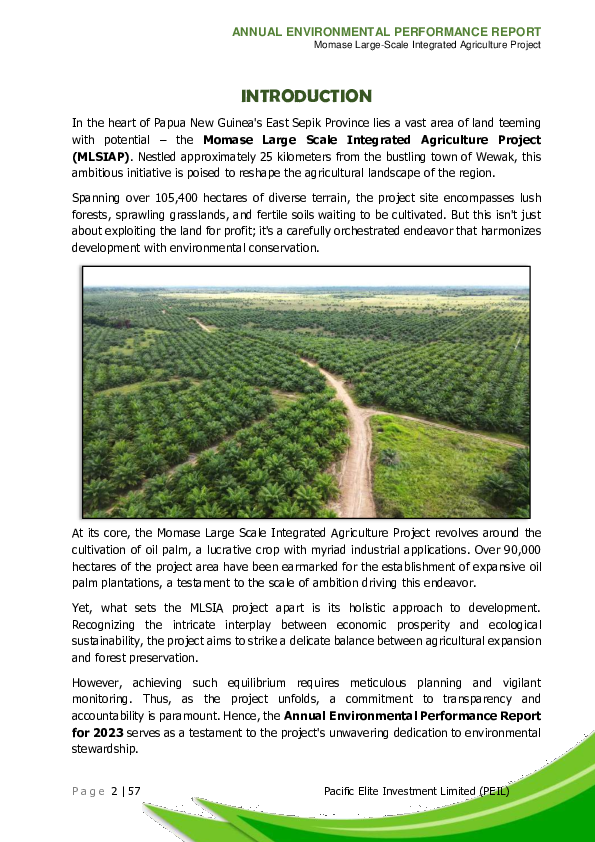

In the heart of Papua New Guinea's East Sepik Province lies a vast area of land teeming

with potential – the Momase Large Scale Integrated Agriculture Project

(MLSIAP). Nestled approximately 25 kilometers from the bustling town of Wewak, this

ambitious initiative is poised to reshape the agricultural landscape of the region.

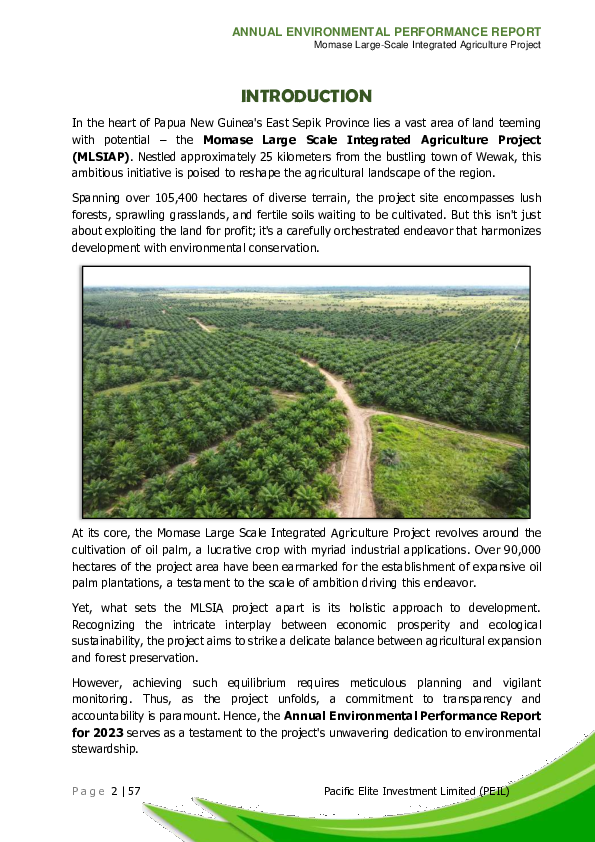

Spanning over 105,400 hectares of diverse terrain, the project site encompasses lush

forests, sprawling grasslands, and fertile soils waiting to be cultivated. But this isn't just

about exploiting the land for profit; it's a carefully orchestrated endeavor that harmonizes

development with environmental conservation.

At its core, the Momase Large Scale Integrated Agriculture Project revolves around the

cultivation of oil palm, a lucrative crop with myriad industrial applications. Over 90,000

hectares of the project area have been earmarked for the establishment of expansive oil

palm plantations, a testament to the scale of ambition driving this endeavor.

Yet, what sets the MLSIA project apart is its holistic approach to development.

Recognizing the intricate interplay between economic prosperity and ecological

sustainability, the project aims to strike a delicate balance between agricultural expansion

and forest preservation.

However, achieving such equilibrium requires meticulous planning and vigilant

monitoring. Thus, as the project unfolds, a commitment to transparency and

accountability is paramount. Hence, the Annual Environmental Performance Report

for 2023 serves as a testament to the project's unwavering dedication to environmental

stewardship.

P a g e 2 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Within the pages of this report lie insights into the project's progress, challenges

encountered, and measures taken to mitigate environmental impact. It serves not only

as a regulatory requirement but also as a testament to the project's ethos – a testament

to the conviction that progress need not come at the expense of nature.

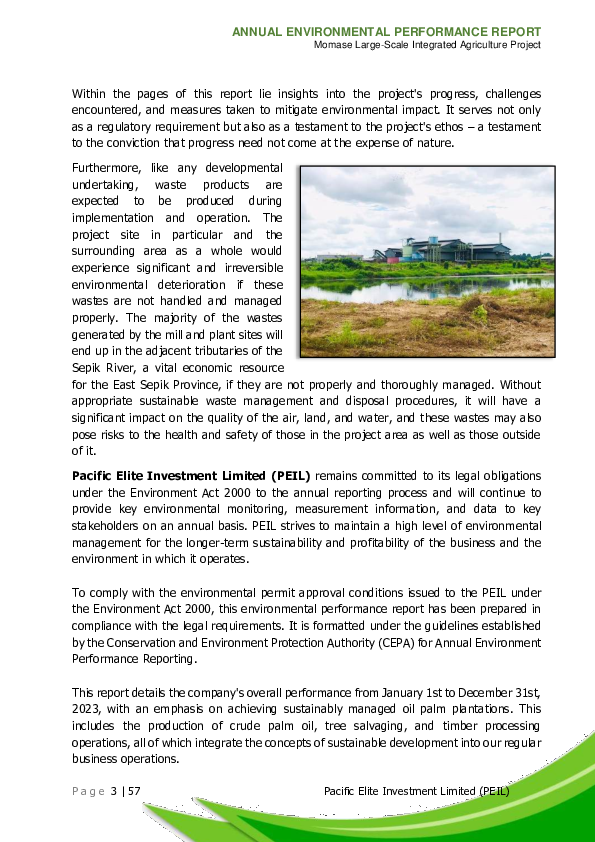

Furthermore, like any developmental

undertaking, waste products are

expected to be produced during

implementation and operation. The

project site in particular and the

surrounding area as a whole would

experience significant and irreversible

environmental deterioration if these

wastes are not handled and managed

properly. The majority of the wastes

generated by the mill and plant sites will

end up in the adjacent tributaries of the

Sepik River, a vital economic resource

for the East Sepik Province, if they are not properly and thoroughly managed. Without

appropriate sustainable waste management and disposal procedures, it will have a

significant impact on the quality of the air, land, and water, and these wastes may also

pose risks to the health and safety of those in the project area as well as those outside

of it.

Pacific Elite Investment Limited (PEIL) remains committed to its legal obligations

under the Environment Act 2000 to the annual reporting process and will continue to

provide key environmental monitoring, measurement information, and data to key

stakeholders on an annual basis. PEIL strives to maintain a high level of environmental

management for the longer-term sustainability and profitability of the business and the

environment in which it operates.

To comply with the environmental permit approval conditions issued to the PEIL under

the Environment Act 2000, this environmental performance report has been prepared in

compliance with the legal requirements. It is formatted under the guidelines established

by the Conservation and Environment Protection Authority (CEPA) for Annual Environment

Performance Reporting.

This report details the company's overall performance from January 1st to December 31st,

2023, with an emphasis on achieving sustainably managed oil palm plantations. This

includes the production of crude palm oil, tree salvaging, and timber processing

operations, all of which integrate the concepts of sustainable development into our regular

business operations.

P a g e 3 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Our foremost priority revolves around consistently enhancing our environmental

performance. This commitment stems from our overarching business goals, striving to

attain predefined targets, and adhering to legal mandates and regulations, including

various environmental permit stipulations. We aim to operate our business in a manner

that is both efficient and environmentally sustainable over the long haul.

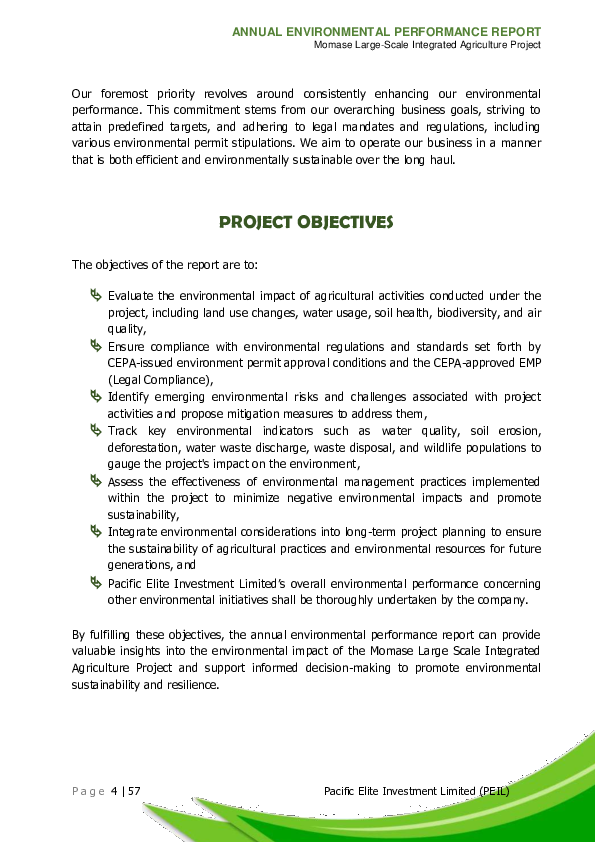

PROJECT OBJECTIVES

The objectives of the report are to:

Evaluate the environmental impact of agricultural activities conducted under the

project, including land use changes, water usage, soil health, biodiversity, and air

quality,

Ensure compliance with environmental regulations and standards set forth by

CEPA-issued environment permit approval conditions and the CEPA-approved EMP

(Legal Compliance),

Identify emerging environmental risks and challenges associated with project

activities and propose mitigation measures to address them,

Track key environmental indicators such as water quality, soil erosion,

deforestation, water waste discharge, waste disposal, and wildlife populations to

gauge the project's impact on the environment,

Assess the effectiveness of environmental management practices implemented

within the project to minimize negative environmental impacts and promote

sustainability,

Integrate environmental considerations into long-term project planning to ensure

the sustainability of agricultural practices and environmental resources for future

generations, and

Pacific Elite Investment Limited’s overall environmental performance concerning

other environmental initiatives shall be thoroughly undertaken by the company.

By fulfilling these objectives, the annual environmental performance report can provide

valuable insights into the environmental impact of the Momase Large Scale Integrated

Agriculture Project and support informed decision-making to promote environmental

sustainability and resilience.

P a g e 4 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

I. ENVIRONMENTAL PERFORMANCE

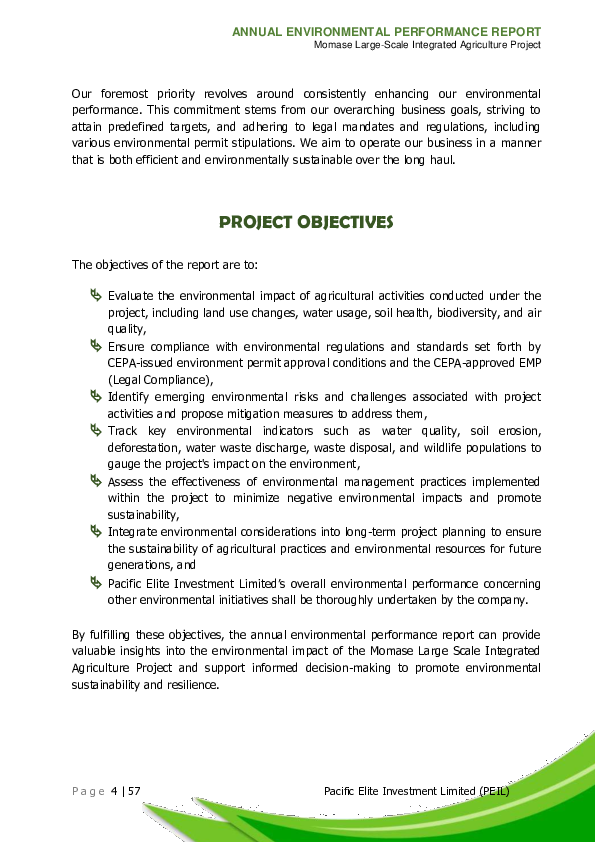

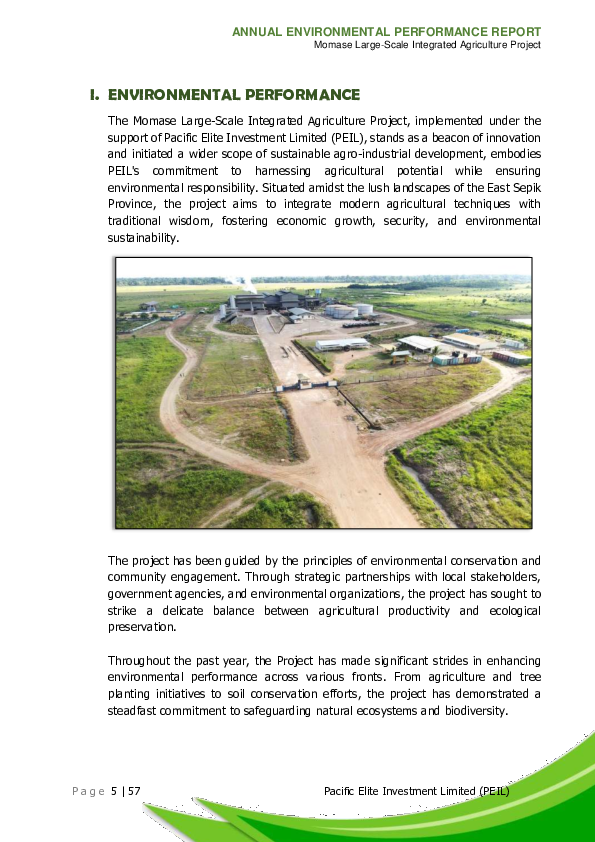

The Momase Large-Scale Integrated Agriculture Project, implemented under the

support of Pacific Elite Investment Limited (PEIL), stands as a beacon of innovation

and initiated a wider scope of sustainable agro-industrial development, embodies

PEIL's commitment to harnessing agricultural potential while ensuring

environmental responsibility. Situated amidst the lush landscapes of the East Sepik

Province, the project aims to integrate modern agricultural techniques with

traditional wisdom, fostering economic growth, security, and environmental

sustainability.

The project has been guided by the principles of environmental conservation and

community engagement. Through strategic partnerships with local stakeholders,

government agencies, and environmental organizations, the project has sought to

strike a delicate balance between agricultural productivity and ecological

preservation.

Throughout the past year, the Project has made significant strides in enhancing

environmental performance across various fronts. From agriculture and tree

planting initiatives to soil conservation efforts, the project has demonstrated a

steadfast commitment to safeguarding natural ecosystems and biodiversity.

P a g e 5 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Moreover, the MLSIA Project has prioritized community involvement and capacity

building, empowering local farmers with knowledge and skills to adopt sustainable

agricultural practices. By fostering a culture of environmental stewardship and

resilience, the project aims to create lasting benefits for present and future

generations.

As we delve into the Annual Environmental Performance Report for CY 2023, it is

with a sense of pride and responsibility that we reflect upon the achievements and

challenges encountered along the way. Through transparent assessment and open

dialogue, we strive to uphold the highest standards of environmental accountability

and pave the way for a greener, more prosperous future in the region and beyond.

A. Water Extraction

This report details the company's overall performance from January 1st to

December 31st, 2023, with an emphasis on achieving sustainably managed oil

palm plantations. This includes the production of crude palm oil, tree salvaging,

and timber processing operations, all of which integrate the concepts of sustainable

development into our regular business operations.

Last December 5, 2008, the project was

granted Environmental Permits to Discharge

Waste {WD-L3-(196)} and extract water

{(WE-L3 (150)} with approval to commence

on January 2, 2009. Hereafter, the company

applied to amend the Environment Permits

(EPs) to discharge waste and extract waters

which were granted last 19th of November

2021 and under the transformation of the

Department of Environment and Conservation

(DEC) into Conservation and Environment

Protection Authority (CEPA), the

Environmental Permit Number changed to

WATER EXTRACTION POINT

{EP-L3-(806)} which combines the two EPs.

P a g e 6 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Table 1. Summary of Water sampling extraction under PEIL for the year 2023.

Water Extraction LOCATION &

SOURCE USAGE

Point COORDINATES

WSE - 01 Sepik River Plywood Plant (KPL) Industrial & Domestic

Easting: 808 230

Northing: 9 537 951

WSE - 02 Urr-u Creek (Pongi) Oil Palm Mill-SPOL Industrial & Domestic

Easting: 801 748

Northing: 9 542 754

WSE - 03 Pond Turubu Township Domestic/Workshop

Easting: 806 659

Northing: 9 566 472

WSE - 04 Pond Kenyare Compound Domestic/Workshop

Easting: 808 846

Northing: 9 572 491

WSE – 05 Mawit Creek Mawit basecamp Domestic/Workshop

(Brinangat) Easting: 807 251

Northing: 9 586 246

WSE - 06 Urr-u Creek (Pongi) Ibap Nursery Nursery Irrigation

Easting: 810 073

Northing: 9 561 011

Note: NARI Chemistry Lab Water Quality Sampling Analysis Result (See Appendix 6)

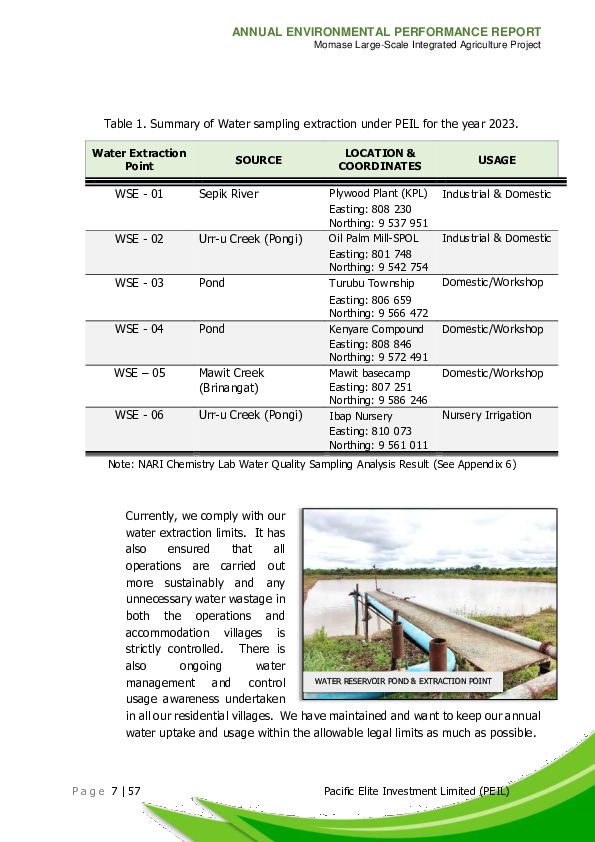

Currently, we comply with our

water extraction limits. It has

also ensured that all

operations are carried out

more sustainably and any

unnecessary water wastage in

both the operations and

accommodation villages is

strictly controlled. There is

also ongoing water

management and control WATER RESERVOIR POND & EXTRACTION POINT

usage awareness undertaken

in all our residential villages. We have maintained and want to keep our annual

water uptake and usage within the allowable legal limits as much as possible.

P a g e 7 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

1. Water Quality Monitoring – Drinking Water

The water requirement in the camp for domestic and industrial purposes will

be supplied both through rainwater and surface water from different

creeks/rivers and ponds located nearby. Water abstraction from rivers, creeks,

ponds, and surface water will be conducted with the use of a water pump

(diesel-driven) throughout the year only on an as-needed basis. Because the

Project Area has several high monthly rainfalls, the camp’s water supply needs

will be mainly addressed through the water tanks established to collect

rainwater. Turubu Township, and Mundo-mundo estate rainwater were

collected for domestic use consumption.

During the dry period, water

will be taken from the

constructed reservoir near the

creek, river, and pond and

supplied to the camp through

a water motor pump (diesel-

driven). Water will be stored

in the centralized huge (15m3

- capacity) water tank

mounted in the platform so

that the water will flow freely

to respective faucets using gravitational force. The water pump will

automatically shut off once the desired water level in the tank is attained. In

this way, fuel, and oil consumption of the motor is minimized.

On the other hand, water requirements for the Ibap nursery and palm oil mill

will be supplied from the water abstracted from Urr-u Creek (Pongi). Again, a

centralized huge (20m3 - capacity) water tank will be installed using the same

principle as the one used in the camp during the dry season.

P a g e 8 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

With the increasingly severe pollution of drinking water resources, people's

awareness of the protection of drinking water gradually strengthened, and

management departments increased the intensity of water resource

detection.

Amid the fourth quarter of the previous year, a significant decision rippled

through the corridors of management: the relocation of staff and employees

residing in Mawit Main Camp to Kanduanum. This decision, while abrupt,

was rooted in a pragmatic rationale. In light of these challenges,

management recognized the need for a more sustainable solution.

Kanduanum, situated on firmer ground and boasting more robust facilities,

emerged as the logical choice for relocation. Its proximity to essential

resources and infrastructure made it an ideal candidate to accommodate

the displaced staff and employees from Mawit Camp. Additionally,

Kanduanum offered a more secure and stable environment, mitigating the

risks associated with continued residence in Mawit Camp.

Ultimately, the decision to transfer the staff and employees from Mawit

Camp to Kanduanum was a strategic move aimed at ensuring the continued

productivity and welfare of the workforce. As the transition unfolded, it

became evident that this decision would not only safeguard the interests of

the individuals involved but also pave the way for future growth and

development. For now, Mawit Main Camp is no longer exists and was not

also included in this report (Domestic Use).

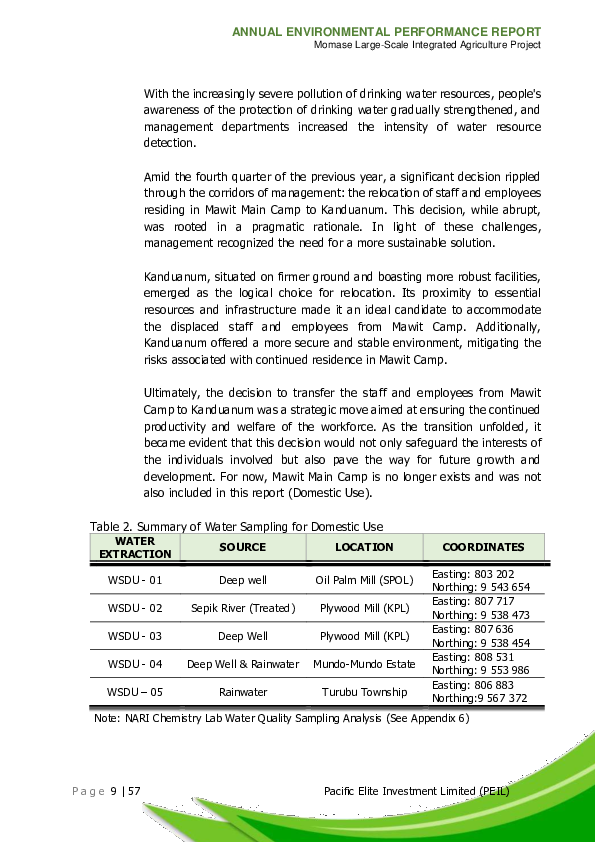

Table 2. Summary of Water Sampling for Domestic Use

WATER

SOURCE LOCATION COORDINATES

EXTRACTION

Easting: 803 202

WSDU - 01 Deep well Oil Palm Mill (SPOL)

Northing: 9 543 654

Easting: 807 717

WSDU - 02 Sepik River (Treated) Plywood Mill (KPL)

Northing: 9 538 473

Easting: 807 636

WSDU - 03 Deep Well Plywood Mill (KPL)

Northing: 9 538 454

Easting: 808 531

WSDU - 04 Deep Well & Rainwater Mundo-Mundo Estate

Northing: 9 553 986

Easting: 806 883

WSDU – 05 Rainwater Turubu Township

Northing:9 567 372

Note: NARI Chemistry Lab Water Quality Sampling Analysis (See Appendix 6)

P a g e 9 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

a. Domestic Water

Water for domestic use is obtained from

both surface and underground water

sources. We periodically check and

monitor all PEIL private water sources for

water sampling to make sure the quality of

our drinking water is within the legal

limitations outlined in our Environmental

Permits - Water Extraction and in

compliance with the PNG Public Health

(Drinking) Water Quality Standards. Every

source of abstraction has a different set of

water samples taken. As of right now, PEIL

analyzes every water sample through the

NARI Chemistry Lab.

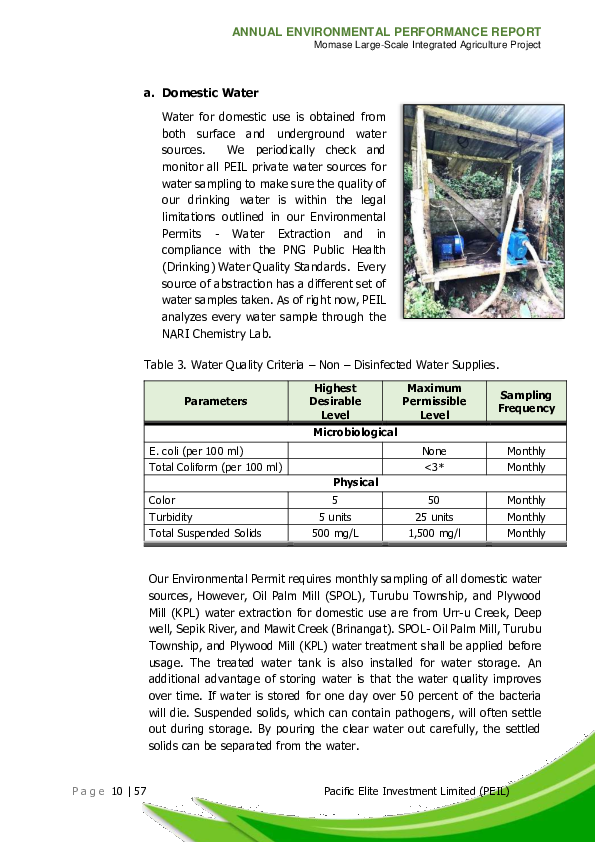

Table 3. Water Quality Criteria – Non – Disinfected Water Supplies.

Highest Maximum

Sampling

Parameters Desirable Permissible

Frequency

Level Level

Microbiological

E. coli (per 100 ml) None Monthly

Total Coliform (per 100 ml) <3* Monthly

Physical

Color 5 50 Monthly

Turbidity 5 units 25 units Monthly

Total Suspended Solids 500 mg/L 1,500 mg/l Monthly

Our Environmental Permit requires monthly sampling of all domestic water

sources, However, Oil Palm Mill (SPOL), Turubu Township, and Plywood

Mill (KPL) water extraction for domestic use are from Urr-u Creek, Deep

well, Sepik River, and Mawit Creek (Brinangat). SPOL- Oil Palm Mill, Turubu

Township, and Plywood Mill (KPL) water treatment shall be applied before

usage. The treated water tank is also installed for water storage. An

additional advantage of storing water is that the water quality improves

over time. If water is stored for one day over 50 percent of the bacteria

will die. Suspended solids, which can contain pathogens, will often settle

out during storage. By pouring the clear water out carefully, the settled

solids can be separated from the water.

P a g e 10 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

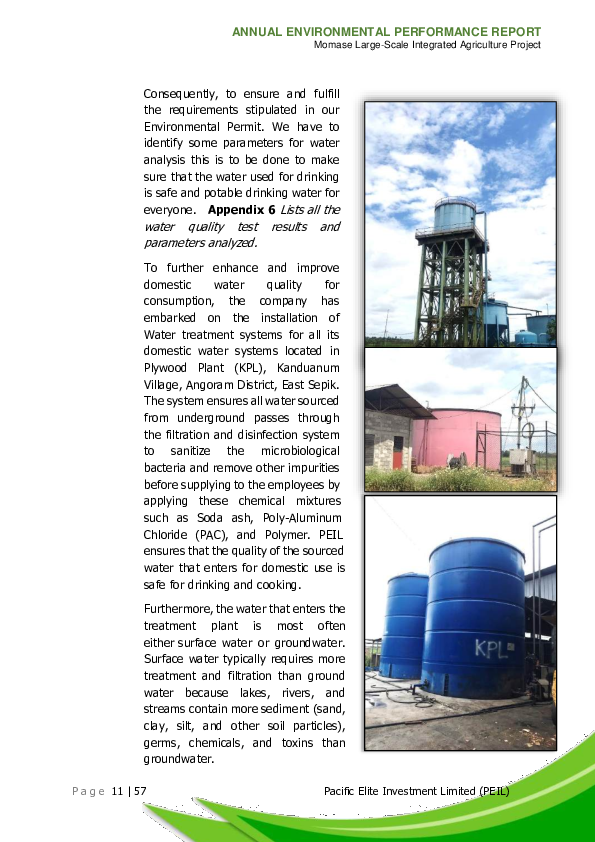

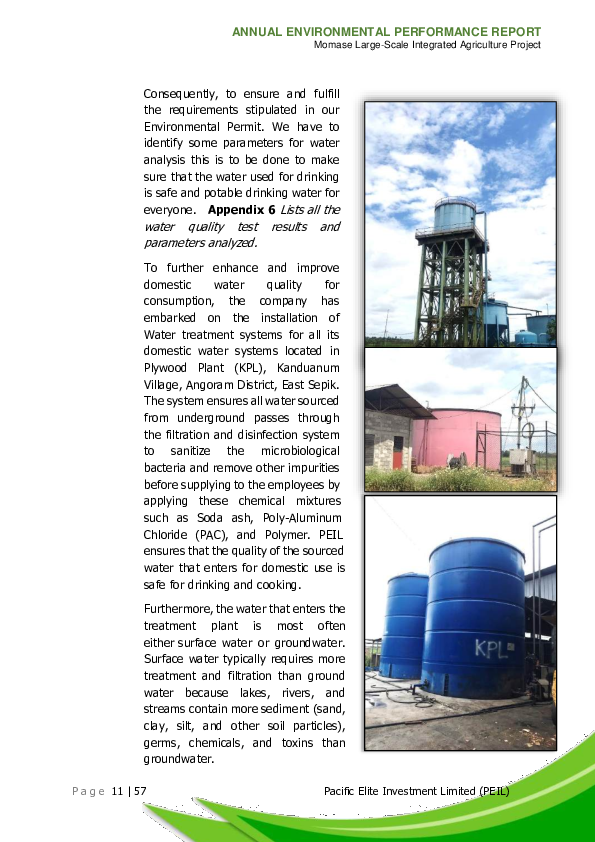

Consequently, to ensure and fulfill

the requirements stipulated in our

Environmental Permit. We have to

identify some parameters for water

analysis this is to be done to make

sure that the water used for drinking

is safe and potable drinking water for

everyone. Appendix 6 Lists all the

water quality test results and

parameters analyzed.

To further enhance and improve

domestic water quality for

consumption, the company has

embarked on the installation of

Water treatment systems for all its

domestic water systems located in

Plywood Plant (KPL), Kanduanum

Village, Angoram District, East Sepik.

The system ensures all water sourced

from underground passes through

the filtration and disinfection system

to sanitize the microbiological

bacteria and remove other impurities

before supplying to the employees by

applying these chemical mixtures

such as Soda ash, Poly-Aluminum

Chloride (PAC), and Polymer. PEIL

ensures that the quality of the sourced

water that enters for domestic use is

safe for drinking and cooking.

Furthermore, the water that enters the

treatment plant is most often

either surface water or groundwater.

Surface water typically requires more

treatment and filtration than ground

water because lakes, rivers, and

streams contain more sediment (sand,

clay, silt, and other soil particles),

germs, chemicals, and toxins than

groundwater.

P a g e 11 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

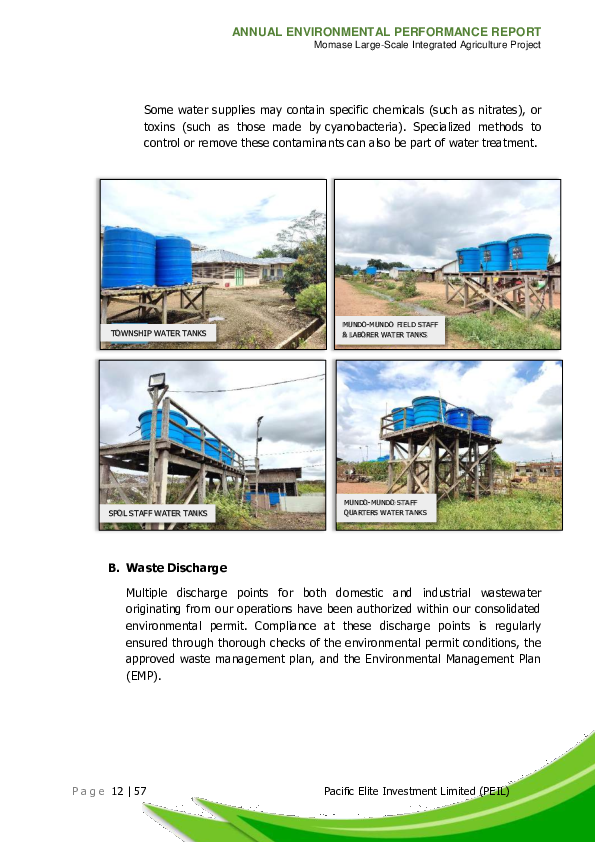

Some water supplies may contain specific chemicals (such as nitrates), or

toxins (such as those made by cyanobacteria). Specialized methods to

control or remove these contaminants can also be part of water treatment.

MUNDO-MUNDO FIELD STAFF

TOWNSHIP WATER TANKS & LABORER WATER TANKS

MUNDO-MUNDO STAFF

SPOL STAFF WATER TANKS QUARTERS WATER TANKS

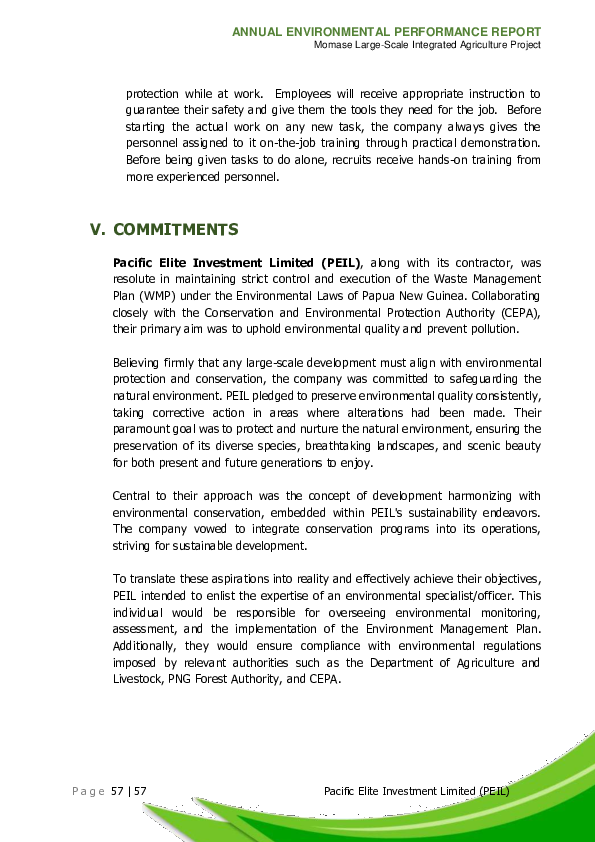

B. Waste Discharge

Multiple discharge points for both domestic and industrial wastewater

originating from our operations have been authorized within our consolidated

environmental permit. Compliance at these discharge points is regularly

ensured through thorough checks of the environmental permit conditions, the

approved waste management plan, and the Environmental Management Plan

(EMP).

P a g e 12 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

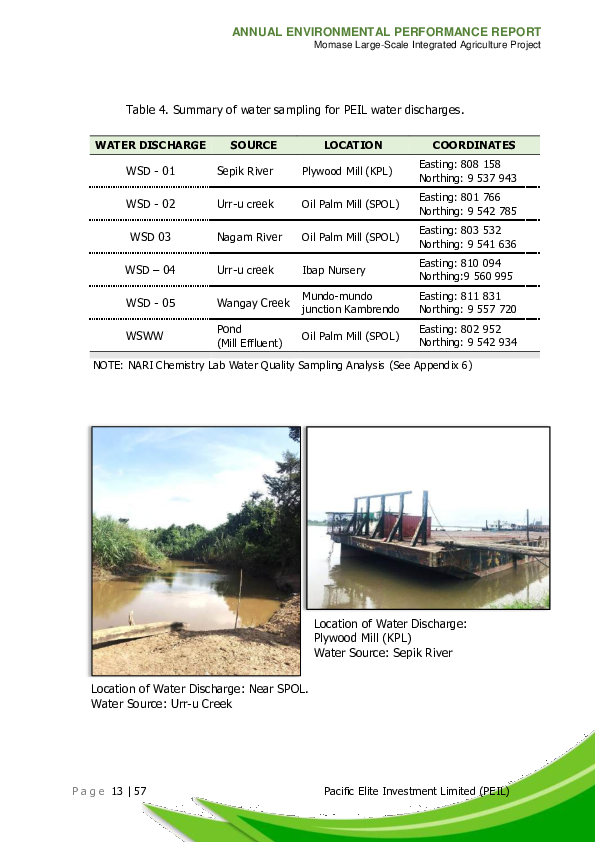

Table 4. Summary of water sampling for PEIL water discharges.

WATER DISCHARGE SOURCE LOCATION COORDINATES

Easting: 808 158

WSD - 01 Sepik River Plywood Mill (KPL)

Northing: 9 537 943

Easting: 801 766

WSD - 02 Urr-u creek Oil Palm Mill (SPOL)

Northing: 9 542 785

Easting: 803 532

WSD 03 Nagam River Oil Palm Mill (SPOL)

Northing: 9 541 636

Easting: 810 094

WSD – 04 Urr-u creek Ibap Nursery

Northing:9 560 995

Mundo-mundo Easting: 811 831

WSD - 05 Wangay Creek

junction Kambrendo Northing: 9 557 720

Pond Easting: 802 952

WSWW Oil Palm Mill (SPOL)

(Mill Effluent) Northing: 9 542 934

NOTE: NARI Chemistry Lab Water Quality Sampling Analysis (See Appendix 6)

Location of Water Discharge:

Plywood Mill (KPL)

Water Source: Sepik River

Location of Water Discharge: Near SPOL.

Water Source: Urr-u Creek

P a g e 13 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

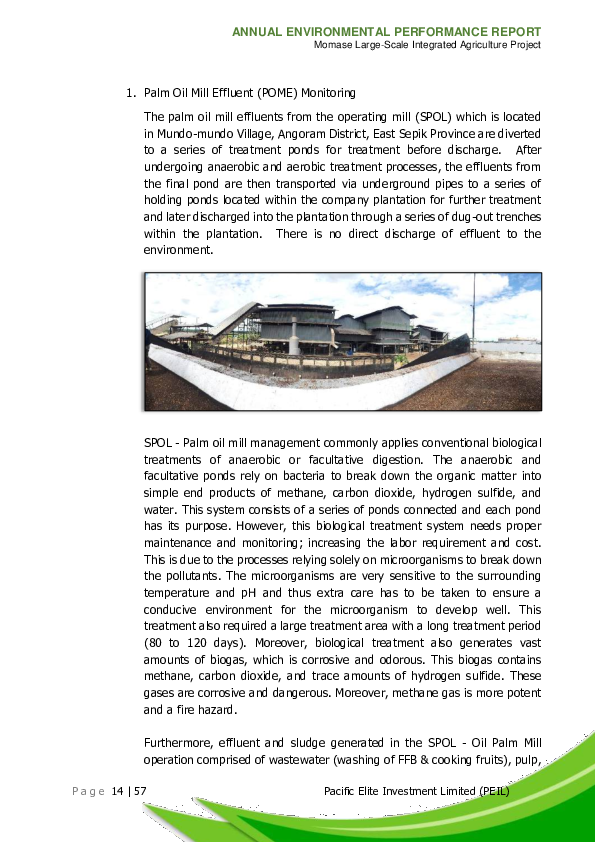

1. Palm Oil Mill Effluent (POME) Monitoring

The palm oil mill effluents from the operating mill (SPOL) which is located

in Mundo-mundo Village, Angoram District, East Sepik Province are diverted

to a series of treatment ponds for treatment before discharge. After

undergoing anaerobic and aerobic treatment processes, the effluents from

the final pond are then transported via underground pipes to a series of

holding ponds located within the company plantation for further treatment

and later discharged into the plantation through a series of dug-out trenches

within the plantation. There is no direct discharge of effluent to the

environment.

SPOL - Palm oil mill management commonly applies conventional biological

treatments of anaerobic or facultative digestion. The anaerobic and

facultative ponds rely on bacteria to break down the organic matter into

simple end products of methane, carbon dioxide, hydrogen sulfide, and

water. This system consists of a series of ponds connected and each pond

has its purpose. However, this biological treatment system needs proper

maintenance and monitoring; increasing the labor requirement and cost.

This is due to the processes relying solely on microorganisms to break down

the pollutants. The microorganisms are very sensitive to the surrounding

temperature and pH and thus extra care has to be taken to ensure a

conducive environment for the microorganism to develop well. This

treatment also required a large treatment area with a long treatment period

(80 to 120 days). Moreover, biological treatment also generates vast

amounts of biogas, which is corrosive and odorous. This biogas contains

methane, carbon dioxide, and trace amounts of hydrogen sulfide. These

gases are corrosive and dangerous. Moreover, methane gas is more potent

and a fire hazard.

Furthermore, effluent and sludge generated in the SPOL - Oil Palm Mill

operation comprised of wastewater (washing of FFB & cooking fruits), pulp,

P a g e 14 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

and residual oil will be directed to the series of ponds (Cooling pond,

acidification pond, anaerobic pond, aerobic pond, facultative pond and

finally, the settling pond) constructed by the company. The size of the pond

will depend on the volume of waste and the number of days that these

wastes will stay in the pond during the treatment process.

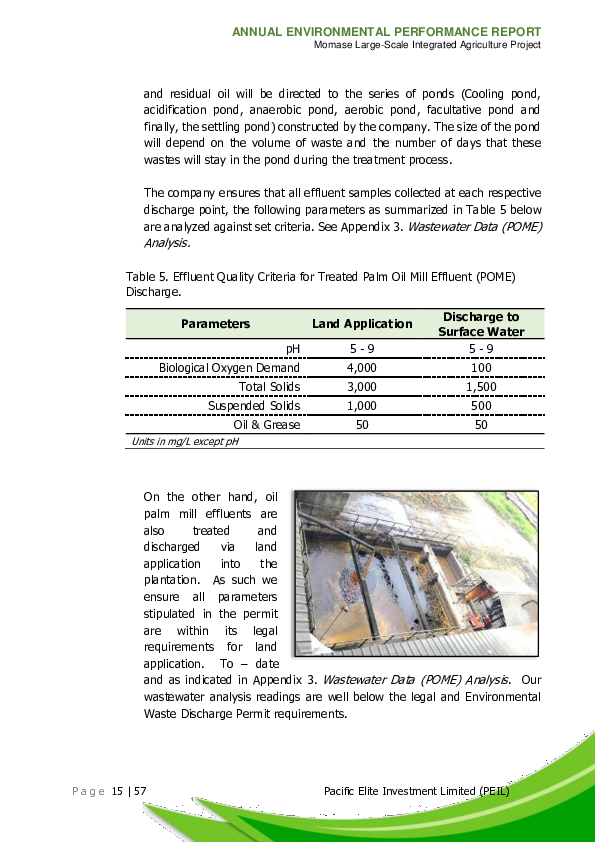

The company ensures that all effluent samples collected at each respective

discharge point, the following parameters as summarized in Table 5 below

are analyzed against set criteria. See Appendix 3. Wastewater Data (POME)

Analysis.

Table 5. Effluent Quality Criteria for Treated Palm Oil Mill Effluent (POME)

Discharge.

Discharge to

Parameters Land Application

Surface Water

pH 5-9 5-9

Biological Oxygen Demand 4,000 100

Total Solids 3,000 1,500

Suspended Solids 1,000 500

Oil & Grease 50 50

Units in mg/L except pH

On the other hand, oil

palm mill effluents are

also treated and

discharged via land

application into the

plantation. As such we

ensure all parameters

stipulated in the permit

are within its legal

requirements for land

application. To – date

and as indicated in Appendix 3. Wastewater Data (POME) Analysis. Our

wastewater analysis readings are well below the legal and Environmental

Waste Discharge Permit requirements.

P a g e 15 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Other parameters such as Oil and Grease and Suspended Solids are also

monitored and results are also shown in Appendix 3. Wastewater Data

(POME) Analysis.

In the event of any non-compliance with our Environmental Permit – Waste

Discharge parameters, an investigation is conducted, and respective site

Managers are informed to ensure corrective measures are taken to correct

such non-conformities. Any significant non-compliance well beyond the

company’s control is reported to management and CEPA is informed.

To date, all POME discharges at respective Environmental Impact Points to

land are and have been well below the legal permit discharge limits as

contained in the Environmental Permit.

P a g e 16 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

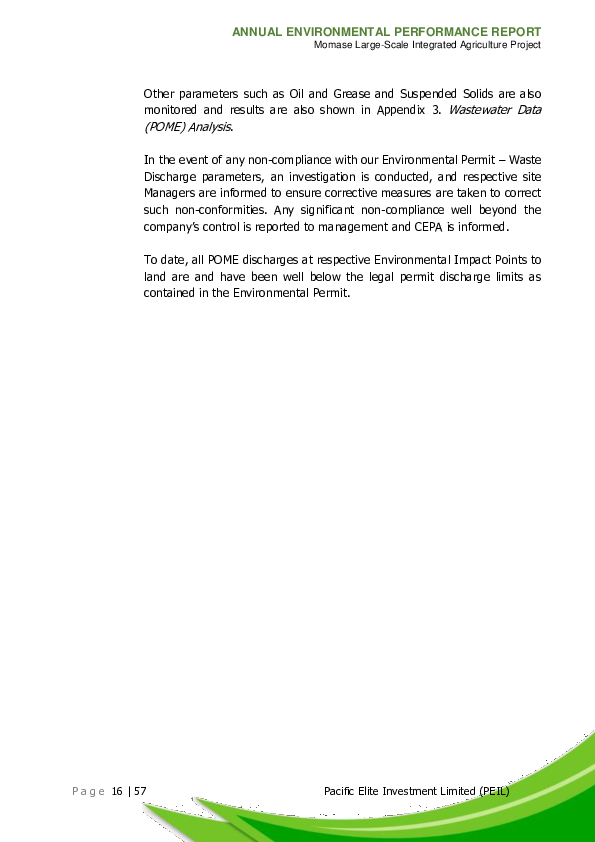

SEPIK OIL PALM MILL (Mill Effluent) located in Mundo-mundo, Angroram

District, East Sepik Province

(BIRDS EYES VIEW)

P a g e 17 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

We undertake ongoing monitoring of the waste streams generated from our

operations

Palm Oil Mill Effluent (POME) discharges from its milling process

Water quality criteria for all treated POME Discharges (POME

wastewater)

Smoke emissions from mill boilers (smoke density meter is under its

procurement phase )

To monitor and assure compliance, the company makes sure that accurate data

is gathered and reported each month. Internal monitoring obligations of the

organization include the analysis and periodic reporting of all data collected

from the various waste streams at various discharge sites.

Any non-compliance with legal and regulatory requirements is checked and

reports are sent to respective sections/departments for investigations and to

take appropriate corrective actions.

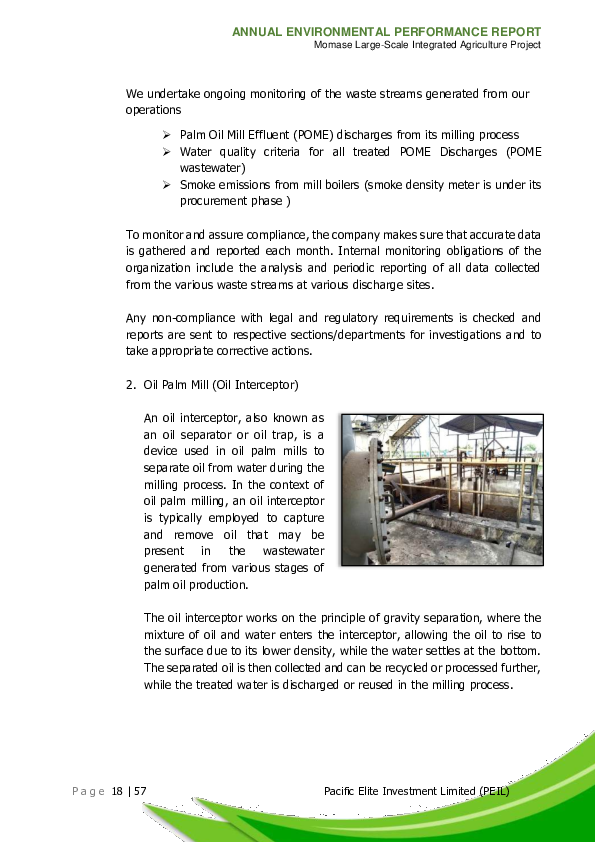

2. Oil Palm Mill (Oil Interceptor)

An oil interceptor, also known as

an oil separator or oil trap, is a

device used in oil palm mills to

separate oil from water during the

milling process. In the context of

oil palm milling, an oil interceptor

is typically employed to capture

and remove oil that may be

present in the wastewater

generated from various stages of

palm oil production.

The oil interceptor works on the principle of gravity separation, where the

mixture of oil and water enters the interceptor, allowing the oil to rise to

the surface due to its lower density, while the water settles at the bottom.

The separated oil is then collected and can be recycled or processed further,

while the treated water is discharged or reused in the milling process.

P a g e 18 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Oil interceptors play a crucial role in

environmental management and

compliance in oil palm mills by

preventing oil contamination of

water bodies and ensuring that

wastewater discharged from the

mill meets regulatory standards for

oil content. Proper maintenance

and operation of oil interceptors are

essential to ensure effective oil-

water separation and minimize environmental impact.

Oil interceptors play several important roles in oil palm mills:

Environmental Protection

•Oil interceptors help prevent oil contamination of water bodies

by removing oil from wastewater before it is discharged. This is

crucial for protecting aquatic ecosystems and complying with

environmental regulations.

Compliance

•Many jurisdictions have regulations regarding the allowable oil

content in wastewater discharged from industrial facilities like oil

palm mills. Oil interceptors help mills meet these regulatory

requirements by effectively removing oil from wastewater.

Resource Recovery

•The oil separated by the interceptor can often be recycled or

processed further, providing an opportunity for resource

recovery and reducing waste.

Efficient Treatment

•By removing oil from wastewater, oil interceptors improve the

efficiency of downstream wastewater treatment processes. This

can reduce the load on treatment systems and improve overall

treatment performance.

Operational Efficiency

•Properly functioning oil interceptors help maintain the smooth

operation of oil palm mills by preventing oil buildup in

drainage systems, which can cause blockages and operational

disruptions.

P a g e 19 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

3. Water Drainage

Drainage water management

practices can target

agronomic goals,

environmental (water quality)

goals, or both. The drainage

outlet can be set at or close

to the soil surface between

growing seasons to recharge

the water table, thereby

temporarily retaining

contaminated water in the

soil profile where it will be

subjected to attenuating and

nitrate-transforming

processes. In addition, it is

possible to raise the outlet

after planting to help increase

WATER DRAINAGE DISCHARGE

water availability to shallow

plant roots and to raise or

lower it throughout the growing season in response to weather conditions.

In some soils, water may even be added during very dry periods to reduce

crop loss from drought, and this practice is termed sub-irrigation. However,

the drain spacing for sub-irrigation has to be half the recommended value

for drainage for the addition of water to be very effective.

On the other hand, proper drainage systems for estate and base camp sites

shall be thoroughly constructed to prevent the accumulation of stagnant

water, which can become a breeding ground for disease-carrying

mosquitoes and other pests. By providing efficient wastewater disposal,

drainage systems contribute to improved sanitation, reducing the risk of

waterborne illnesses and promoting the overall safety of people living inside

the estate and base camps and community well-being as well.

P a g e 20 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

TOWNSHIP DRAINAGE SYSTEM TOWNSHIP DRAINAGE SYSTEM

MUNDO-MUNDO DRAINAGE SYSTEM

4. Sewage

Nestled within the sprawling expanse of

the plantation, a network of facilities

hummed with activity. Amidst the

rhythmic rustle of palm fronds, workers

tended to the vital infrastructure that

supported the cultivation of this lucrative

crop. Among these facilities, sewage and

SPOL STAFF TOILET

septic toilet tanks played a crucial role,

often overlooked but essential for the

sustainable growth of the plantation.

As the plantation flourished,

accommodating a growing workforce and

infrastructure, the issue of waste

management loomed large. The sheer

scale of operations demanded efficient MUNDO-MUNDO TOILET

solutions to handle human waste

effectively while minimizing environmental impact. Herein lay the

significance of sewage and septic toilet tanks.

Unlike conventional sewage systems, which could be impractical and costly

to implement across vast plantations, septic tanks offered a decentralized

and cost-effective alternative. Strategically placed throughout the estate,

these underground chambers served as efficient waste disposal units,

harnessing natural processes to break down organic matter.

P a g e 21 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

The importance of these tanks extended beyond mere waste management.

In the delicate ecosystem of the oil palm plantation, proper sanitation was

paramount to prevent contamination of soil and water sources. Septic tanks

provided a reliable means of containing and treating human waste,

safeguarding the environmental integrity of the plantation.

Moreover, the presence of well-maintained sewage and septic systems

contributed to the overall well-being of the plantation community. By

promoting hygiene and sanitation standards, these facilities helped reduce

the risk of waterborne diseases, ensuring the health and productivity of

workers.

In the broader context of sustainable development, the role of sewage and

septic toilet tanks in oil palm plantations underscored the importance of

integrating environmental stewardship with economic prosperity. Through

efficient waste management practices, plantations could minimize their

ecological footprint while maximizing yields, thus fostering a harmonious

relationship between agriculture and the environment.

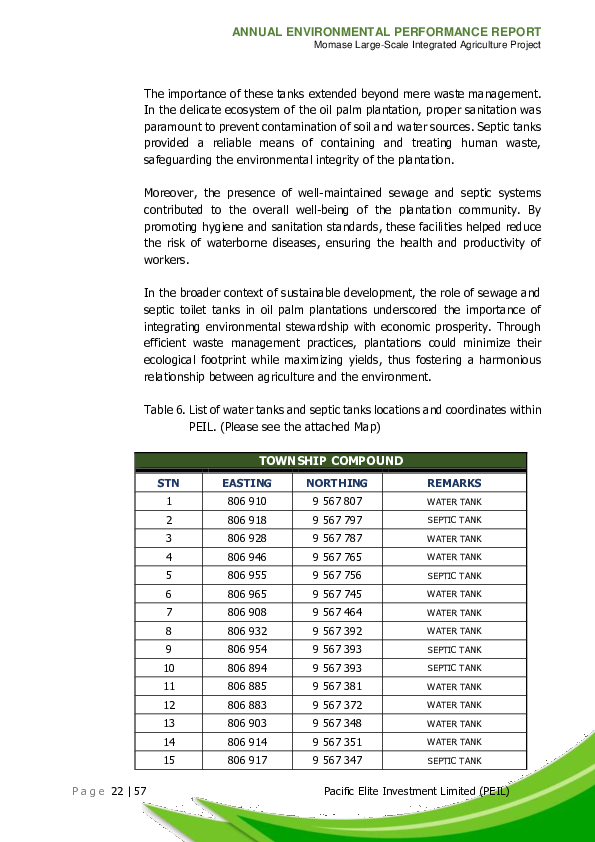

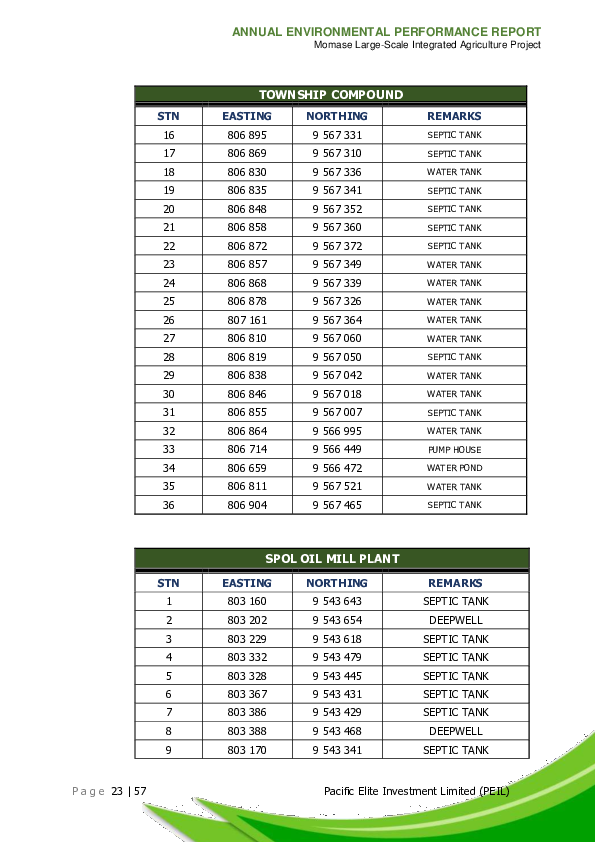

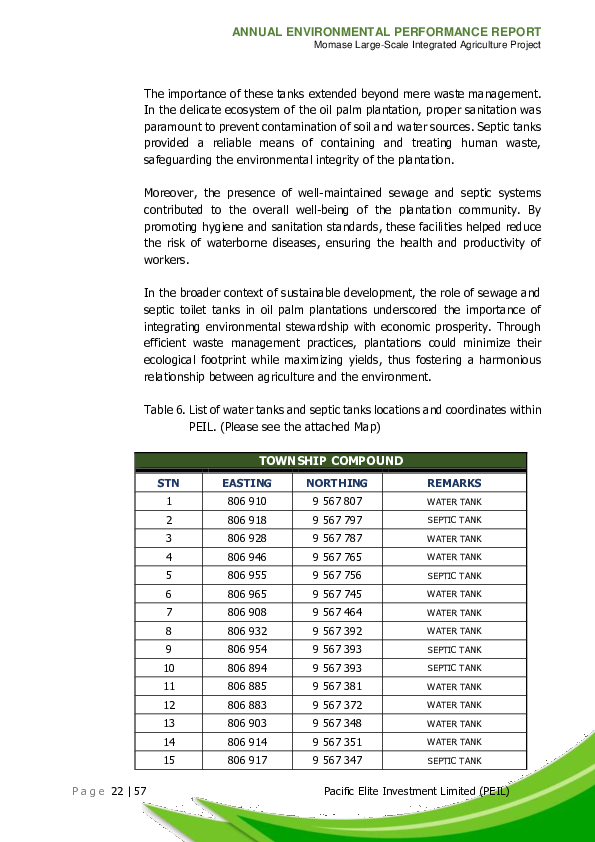

Table 6. List of water tanks and septic tanks locations and coordinates within

PEIL. (Please see the attached Map)

TOWNSHIP COMPOUND

STN EASTING NORTHING REMARKS

1 806 910 9 567 807 WATER TANK

2 806 918 9 567 797 SEPTIC TANK

3 806 928 9 567 787 WATER TANK

4 806 946 9 567 765 WATER TANK

5 806 955 9 567 756 SEPTIC TANK

6 806 965 9 567 745 WATER TANK

7 806 908 9 567 464 WATER TANK

8 806 932 9 567 392 WATER TANK

9 806 954 9 567 393 SEPTIC TANK

10 806 894 9 567 393 SEPTIC TANK

11 806 885 9 567 381 WATER TANK

12 806 883 9 567 372 WATER TANK

13 806 903 9 567 348 WATER TANK

14 806 914 9 567 351 WATER TANK

15 806 917 9 567 347 SEPTIC TANK

P a g e 22 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

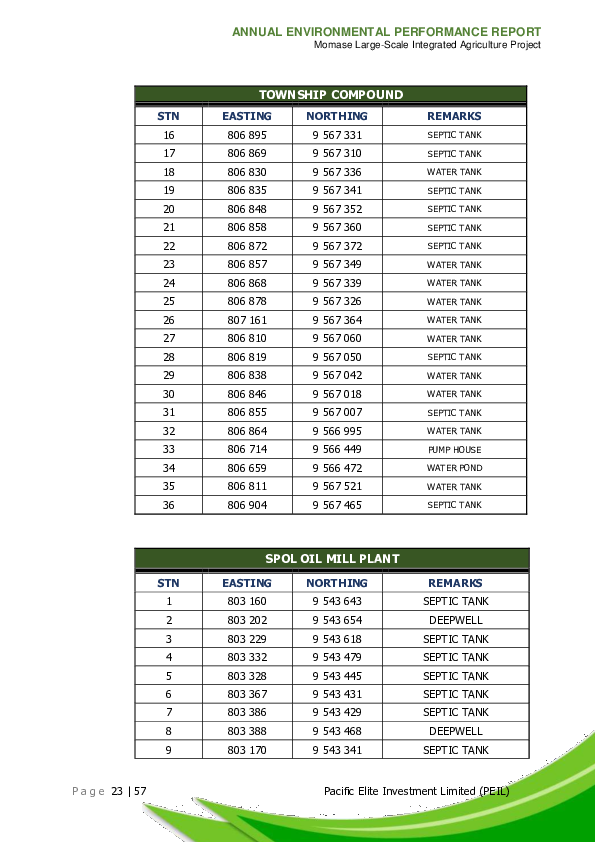

TOWNSHIP COMPOUND

STN EASTING NORTHING REMARKS

16 806 895 9 567 331 SEPTIC TANK

17 806 869 9 567 310 SEPTIC TANK

18 806 830 9 567 336 WATER TANK

19 806 835 9 567 341 SEPTIC TANK

20 806 848 9 567 352 SEPTIC TANK

21 806 858 9 567 360 SEPTIC TANK

22 806 872 9 567 372 SEPTIC TANK

23 806 857 9 567 349 WATER TANK

24 806 868 9 567 339 WATER TANK

25 806 878 9 567 326 WATER TANK

26 807 161 9 567 364 WATER TANK

27 806 810 9 567 060 WATER TANK

28 806 819 9 567 050 SEPTIC TANK

29 806 838 9 567 042 WATER TANK

30 806 846 9 567 018 WATER TANK

31 806 855 9 567 007 SEPTIC TANK

32 806 864 9 566 995 WATER TANK

33 806 714 9 566 449 PUMP HOUSE

34 806 659 9 566 472 WATER POND

35 806 811 9 567 521 WATER TANK

36 806 904 9 567 465 SEPTIC TANK

SPOL OIL MILL PLANT

STN EASTING NORTHING REMARKS

1 803 160 9 543 643 SEPTIC TANK

2 803 202 9 543 654 DEEPWELL

3 803 229 9 543 618 SEPTIC TANK

4 803 332 9 543 479 SEPTIC TANK

5 803 328 9 543 445 SEPTIC TANK

6 803 367 9 543 431 SEPTIC TANK

7 803 386 9 543 429 SEPTIC TANK

8 803 388 9 543 468 DEEPWELL

9 803 170 9 543 341 SEPTIC TANK

P a g e 23 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

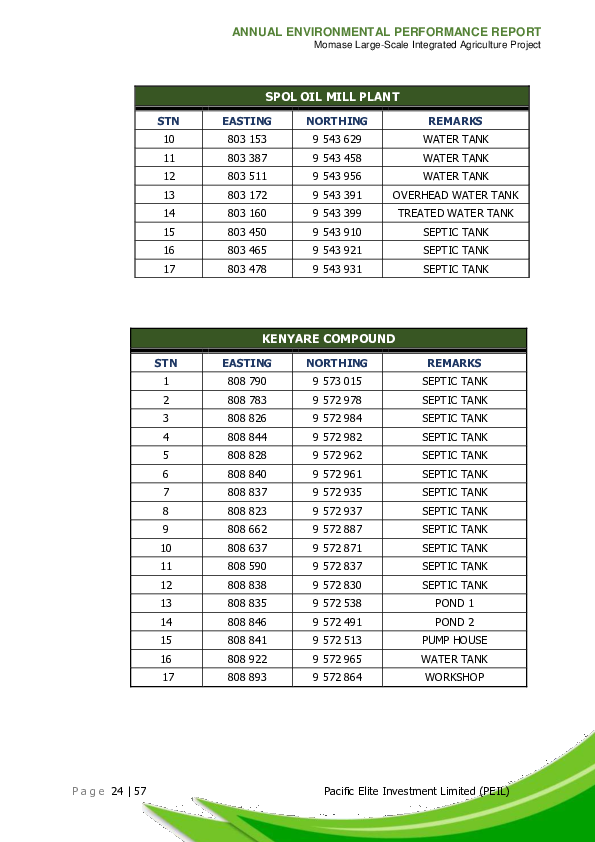

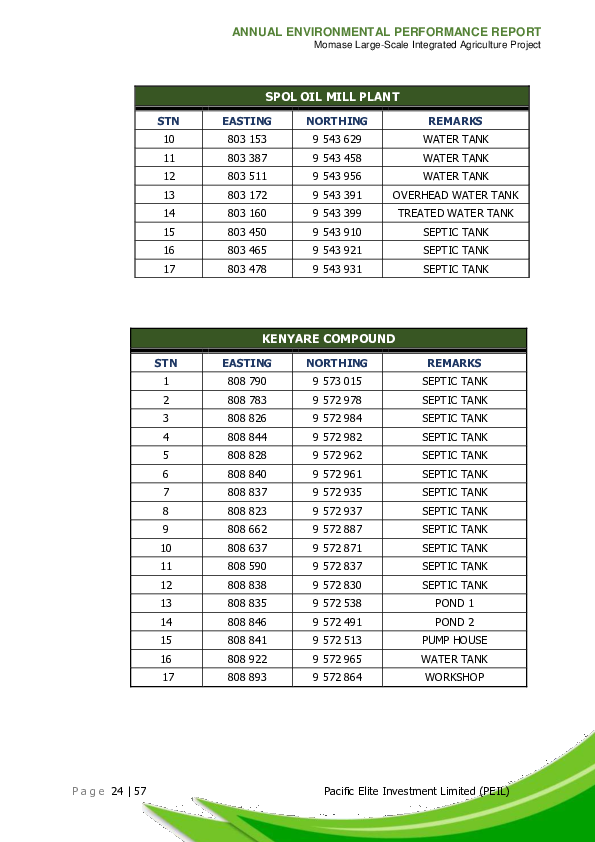

SPOL OIL MILL PLANT

STN EASTING NORTHING REMARKS

10 803 153 9 543 629 WATER TANK

11 803 387 9 543 458 WATER TANK

12 803 511 9 543 956 WATER TANK

13 803 172 9 543 391 OVERHEAD WATER TANK

14 803 160 9 543 399 TREATED WATER TANK

15 803 450 9 543 910 SEPTIC TANK

16 803 465 9 543 921 SEPTIC TANK

17 803 478 9 543 931 SEPTIC TANK

KENYARE COMPOUND

STN EASTING NORTHING REMARKS

1 808 790 9 573 015 SEPTIC TANK

2 808 783 9 572 978 SEPTIC TANK

3 808 826 9 572 984 SEPTIC TANK

4 808 844 9 572 982 SEPTIC TANK

5 808 828 9 572 962 SEPTIC TANK

6 808 840 9 572 961 SEPTIC TANK

7 808 837 9 572 935 SEPTIC TANK

8 808 823 9 572 937 SEPTIC TANK

9 808 662 9 572 887 SEPTIC TANK

10 808 637 9 572 871 SEPTIC TANK

11 808 590 9 572 837 SEPTIC TANK

12 808 838 9 572 830 SEPTIC TANK

13 808 835 9 572 538 POND 1

14 808 846 9 572 491 POND 2

15 808 841 9 572 513 PUMP HOUSE

16 808 922 9 572 965 WATER TANK

17 808 893 9 572 864 WORKSHOP

P a g e 24 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

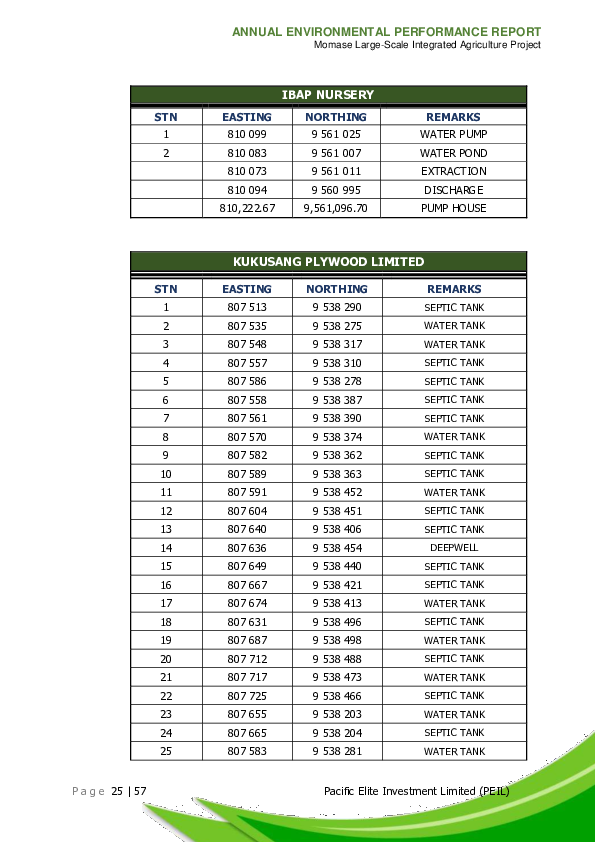

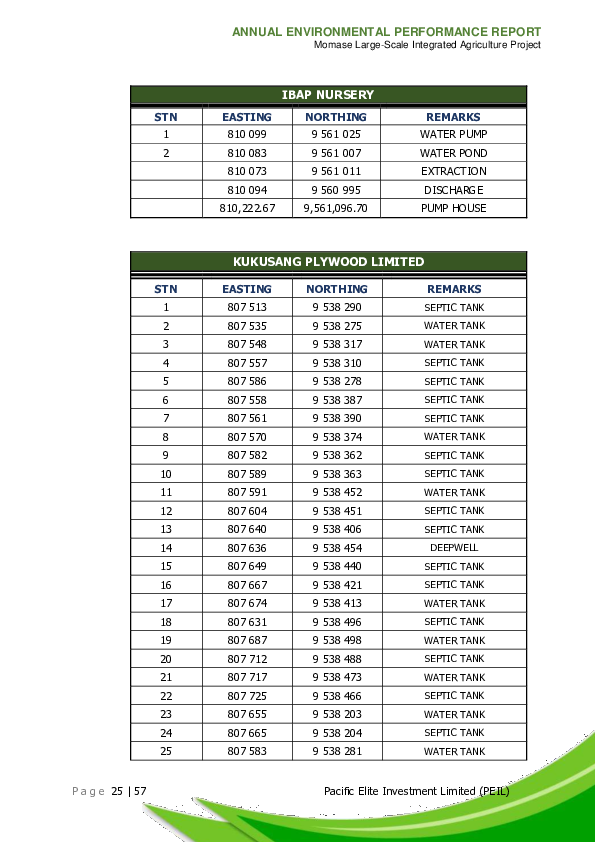

IBAP NURSERY

STN EASTING NORTHING REMARKS

1 810 099 9 561 025 WATER PUMP

2 810 083 9 561 007 WATER POND

810 073 9 561 011 EXTRACTION

810 094 9 560 995 DISCHARGE

810,222.67 9,561,096.70 PUMP HOUSE

KUKUSANG PLYWOOD LIMITED

STN EASTING NORTHING REMARKS

1 807 513 9 538 290 SEPTIC TANK

2 807 535 9 538 275 WATER TANK

3 807 548 9 538 317 WATER TANK

4 807 557 9 538 310 SEPTIC TANK

5 807 586 9 538 278 SEPTIC TANK

6 807 558 9 538 387 SEPTIC TANK

7 807 561 9 538 390 SEPTIC TANK

8 807 570 9 538 374 WATER TANK

9 807 582 9 538 362 SEPTIC TANK

10 807 589 9 538 363 SEPTIC TANK

11 807 591 9 538 452 WATER TANK

12 807 604 9 538 451 SEPTIC TANK

13 807 640 9 538 406 SEPTIC TANK

14 807 636 9 538 454 DEEPWELL

15 807 649 9 538 440 SEPTIC TANK

16 807 667 9 538 421 SEPTIC TANK

17 807 674 9 538 413 WATER TANK

18 807 631 9 538 496 SEPTIC TANK

19 807 687 9 538 498 WATER TANK

20 807 712 9 538 488 SEPTIC TANK

21 807 717 9 538 473 WATER TANK

22 807 725 9 538 466 SEPTIC TANK

23 807 655 9 538 203 WATER TANK

24 807 665 9 538 204 SEPTIC TANK

25 807 583 9 538 281 WATER TANK

P a g e 25 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

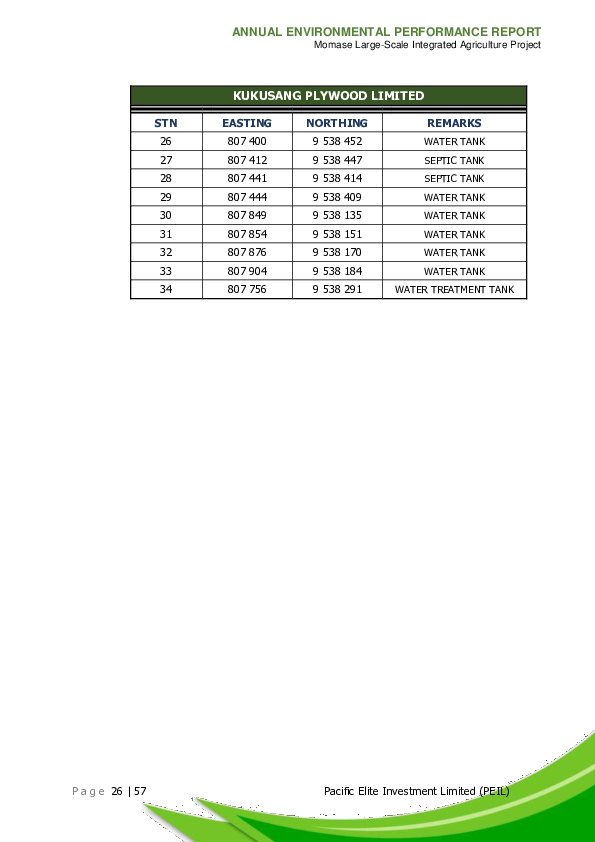

KUKUSANG PLYWOOD LIMITED

STN EASTING NORTHING REMARKS

26 807 400 9 538 452 WATER TANK

27 807 412 9 538 447 SEPTIC TANK

28 807 441 9 538 414 SEPTIC TANK

29 807 444 9 538 409 WATER TANK

30 807 849 9 538 135 WATER TANK

31 807 854 9 538 151 WATER TANK

32 807 876 9 538 170 WATER TANK

33 807 904 9 538 184 WATER TANK

34 807 756 9 538 291 WATER TREATMENT TANK

P a g e 26 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

C. Energy usage

The company (SPOL) aspires

to aggressively conserve

energy and to progressively

reduce reliance on non–

renewable (diesel fuel) energy

towards the use of renewable

energy sources, and reduce

greenhouse gas emissions.

We use waste products from

the mill such as fiber and

endocarp (kernel & shell) to generate power for use in the (boiler 1) milling

process. The mesocarp fiber and endocarp (kernel & shell) generated during

the de-pericarping, and stripping process will be fed as fuel to the boiler

furnace.

About 80% of the energy produced is from renewable resources (turbines).

SPOL ensures that we focus on energy efficiency (management) improvements

in the mills. Hence, most electricity is generated by renewable energy sources

to drive our mill turbines thus decreasing dependence on diesel fuel. Some of

the excessive energy generated is also fed into the grid for domestic

consumption in the company housing and residential areas thus further

reducing its dependency on the use of diesel fuels. (Please see the attached

Appendix 4. Energy Generation).

P a g e 27 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

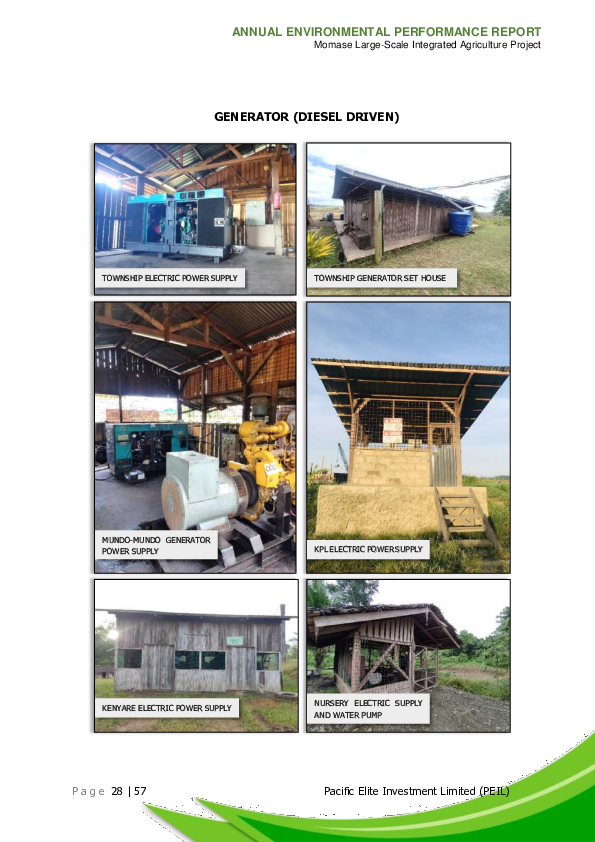

GENERATOR (DIESEL DRIVEN)

TOWNSHIP ELECTRIC POWER SUPPLY TOWNSHIP GENERATOR SET HOUSE

MUNDO-MUNDO GENERATOR

POWER SUPPLY KPL ELECTRIC POWER SUPPLY

NURSERY ELECTRIC SUPPLY

KENYARE ELECTRIC POWER SUPPLY

AND WATER PUMP

P a g e 28 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

The company’s Plywood Plant (KPL) daily operation also uses a diesel-driven

generator set, a crucial component that ensures uninterrupted power supply to

sustain various production processes. Traditionally, the use of diesel-driven

generators has raised environmental concerns due to emissions of pollutants

such as nitrogen oxides (NOx), sulfur oxides (SOx), particulate matter (PM),

and carbon dioxide (CO2). However, in recent years, the plywood industry has

made significant strides toward mitigating these environmental impacts by

adopting environmentally friendly practices in genset usage.

One key approach to enhancing

the environmental performance of

diesel-driven generators in

plywood plants is the integration

of advanced emission control

technologies. These technologies

include diesel particulate filters

(DPF), selective catalytic reduction

(SCR) systems, and exhaust gas

recirculation (EGR), among others.

By incorporating these

technologies, diesel-driven generators can significantly reduce emissions of

harmful pollutants, thus improving air quality both within the plant premises

and in the surrounding environment.

Moreover, plywood plant (KPL) is increasingly exploring alternative fuels and

renewable energy sources to power their operations, further minimizing their

environmental footprint. This may involve the utilization of biodiesel derived

from sustainable sources or the integration of renewable energy technologies

such as solar photovoltaic (PV) systems or biomass boilers. By diversifying their

energy sources and reducing reliance on fossil fuels, plywood plants can

P a g e 29 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

contribute to a more sustainable energy landscape while mitigating the

environmental impact associated with diesel genset usage.

In addition to technological advancements, KPL Plywood Plant is also

implementing best practices in genset maintenance and operation to optimize

fuel efficiency and minimize emissions. Regular maintenance checks, efficient

load management, and proper tuning of diesel-driven generators are essential

steps in ensuring that they operate at peak performance while minimizing their

environmental footprint.

Overall, the use of diesel-driven generators in plywood plants can be made

environmentally friendly through the adoption of advanced emission control

technologies, utilization of alternative fuels, and integration of renewable

energy sources. By embracing these sustainable practices, the plywood industry

can reduce its environmental impact while maintaining reliable and efficient

operations to meet the global demand for wood products.

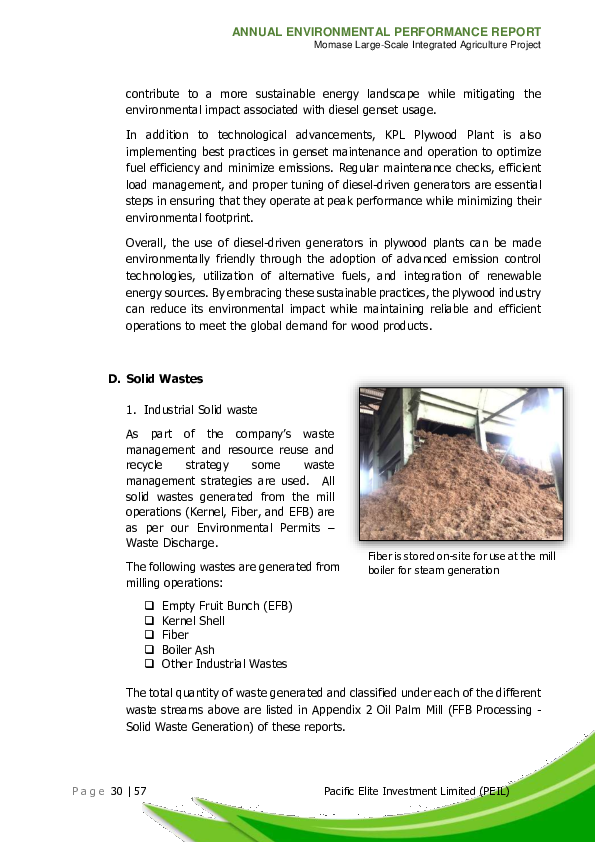

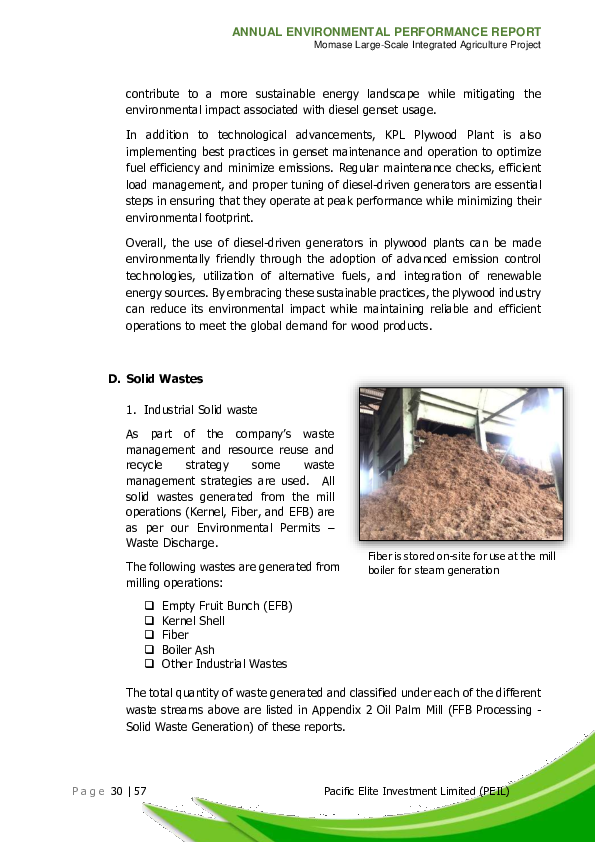

D. Solid Wastes

1. Industrial Solid waste

As part of the company’s waste

management and resource reuse and

recycle strategy some waste

management strategies are used. All

solid wastes generated from the mill

operations (Kernel, Fiber, and EFB) are

as per our Environmental Permits –

Waste Discharge.

Fiber is stored on-site for use at the mill

The following wastes are generated from boiler for steam generation

milling operations:

Empty Fruit Bunch (EFB)

Kernel Shell

Fiber

Boiler Ash

Other Industrial Wastes

The total quantity of waste generated and classified under each of the different

waste streams above are listed in Appendix 2 Oil Palm Mill (FFB Processing -

Solid Waste Generation) of these reports.

P a g e 30 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

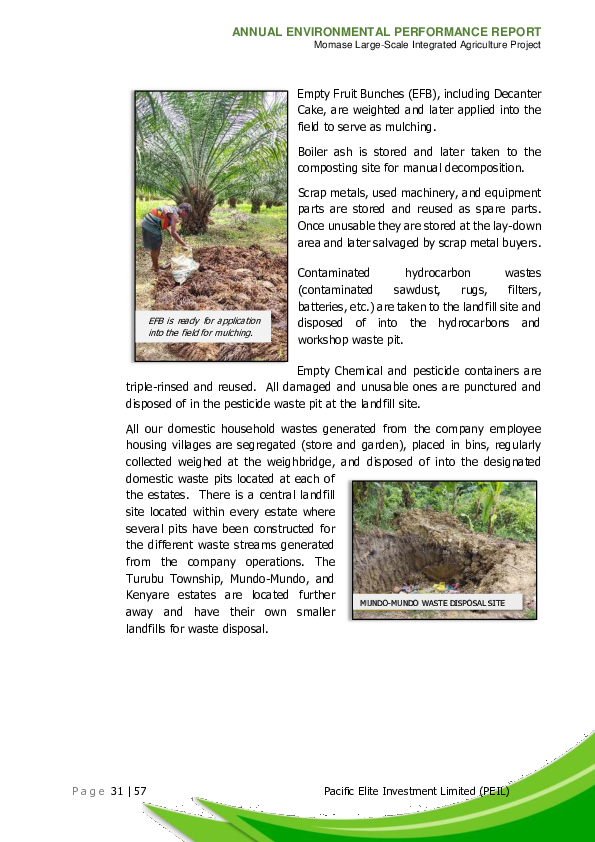

Empty Fruit Bunches (EFB), including Decanter

Cake, are weighted and later applied into the

field to serve as mulching.

Boiler ash is stored and later taken to the

composting site for manual decomposition.

Scrap metals, used machinery, and equipment

parts are stored and reused as spare parts.

Once unusable they are stored at the lay-down

area and later salvaged by scrap metal buyers.

Contaminated hydrocarbon wastes

(contaminated sawdust, rugs, filters,

batteries, etc.) are taken to the landfill site and

EFB is ready for application disposed of into the hydrocarbons and

into the field for mulching.

workshop waste pit.

Empty Chemical and pesticide containers are

triple-rinsed and reused. All damaged and unusable ones are punctured and

disposed of in the pesticide waste pit at the landfill site.

All our domestic household wastes generated from the company employee

housing villages are segregated (store and garden), placed in bins, regularly

collected weighed at the weighbridge, and disposed of into the designated

domestic waste pits located at each of

the estates. There is a central landfill

site located within every estate where

several pits have been constructed for

the different waste streams generated

from the company operations. The

Turubu Township, Mundo-Mundo, and

Kenyare estates are located further

MUNDO-MUNDO WASTE DISPOSAL SITE

away and have their own smaller

landfills for waste disposal.

P a g e 31 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Solid waste segregation in KPL (Staff Quarters)

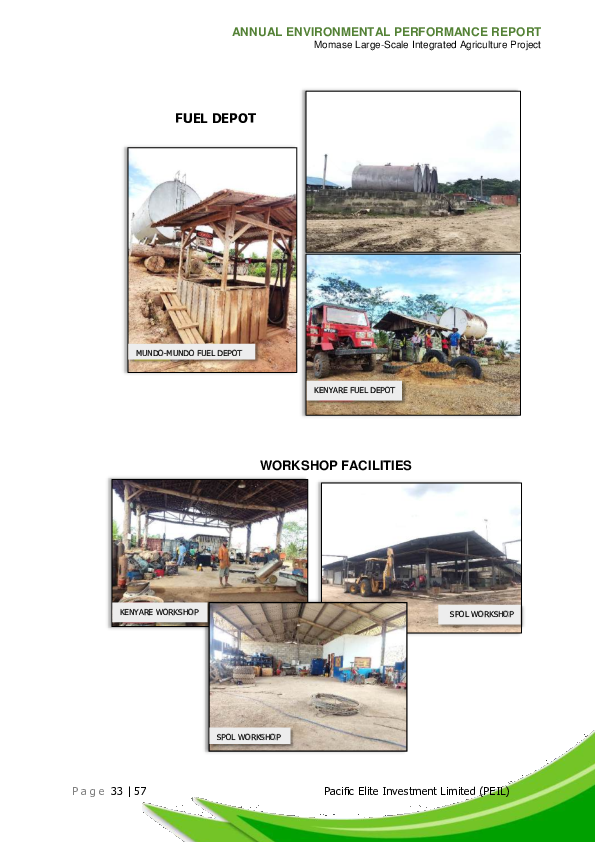

E. Machinery maintenance workshop and fuel storage

The maintenance workshop is operated in

compliance with the CEPA Code of Practice

for Vehicle/Machinery Workshops and

Petroleum (Hydrocarbons) Storage/Usage

Site (DEC, 1997). Workshop area flooring

and drainage include oil water interceptors

to improve the clarity of wash water before

release into the local drainage. The waste

KENYARE PETROL products are handled as prescribed in the

AND OIL STORAGE

Waste Management Plan and described

above. Fuel is currently stored in drums

inside a satisfactory bonded and sheltered shed. Oil Palm Mill and Plywood

Plant Depot for fuel storage are being installed and constructed.

P a g e 32 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

FUEL DEPOT

MUNDO-MUNDO FUEL DEPOT

KENYARE FUEL DEPOT

WORKSHOP FACILITIES

KENYARE WORKSHOP SPOL WORKSHOP

SPOL WORKSHOP

P a g e 33 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

II. ENVIRONMENTAL MANAGEMENT INITIATIVES

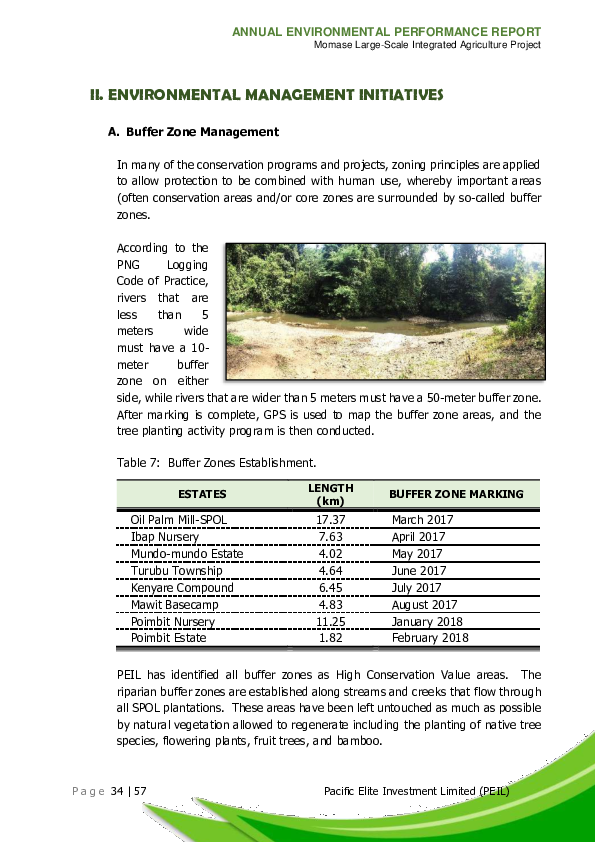

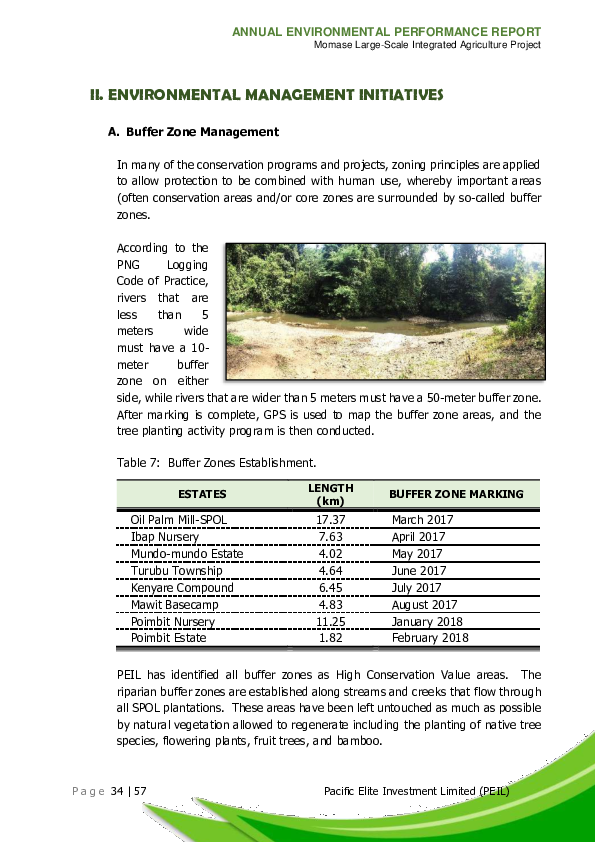

A. Buffer Zone Management

In many of the conservation programs and projects, zoning principles are applied

to allow protection to be combined with human use, whereby important areas

(often conservation areas and/or core zones are surrounded by so-called buffer

zones.

According to the

PNG Logging

Code of Practice,

rivers that are

less than 5

meters wide

must have a 10-

meter buffer

zone on either

side, while rivers that are wider than 5 meters must have a 50-meter buffer zone.

After marking is complete, GPS is used to map the buffer zone areas, and the

tree planting activity program is then conducted.

Table 7: Buffer Zones Establishment.

LENGTH

ESTATES BUFFER ZONE MARKING

(km)

Oil Palm Mill-SPOL 17.37 March 2017

Ibap Nursery 7.63 April 2017

Mundo-mundo Estate 4.02 May 2017

Turubu Township 4.64 June 2017

Kenyare Compound 6.45 July 2017

Mawit Basecamp 4.83 August 2017

Poimbit Nursery 11.25 January 2018

Poimbit Estate 1.82 February 2018

PEIL has identified all buffer zones as High Conservation Value areas. The

riparian buffer zones are established along streams and creeks that flow through

all SPOL plantations. These areas have been left untouched as much as possible

by natural vegetation allowed to regenerate including the planting of native tree

species, flowering plants, fruit trees, and bamboo.

P a g e 34 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

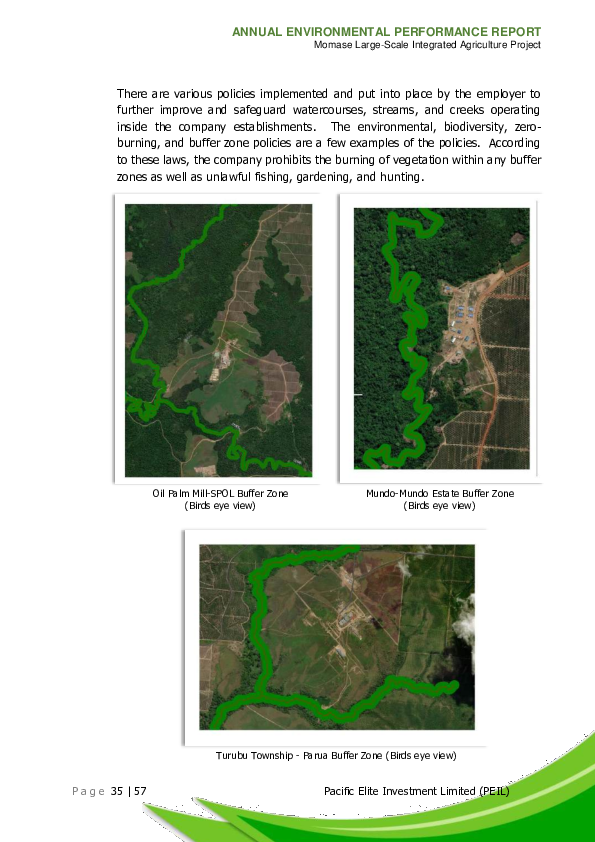

There are various policies implemented and put into place by the employer to

further improve and safeguard watercourses, streams, and creeks operating

inside the company establishments. The environmental, biodiversity, zero-

burning, and buffer zone policies are a few examples of the policies. According

to these laws, the company prohibits the burning of vegetation within any buffer

zones as well as unlawful fishing, gardening, and hunting.

Oil Palm Mill-SPOL Buffer Zone Mundo-Mundo Estate Buffer Zone

(Birds eye view) (Birds eye view)

Turubu Township - Parua Buffer Zone (Birds eye view)

P a g e 35 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

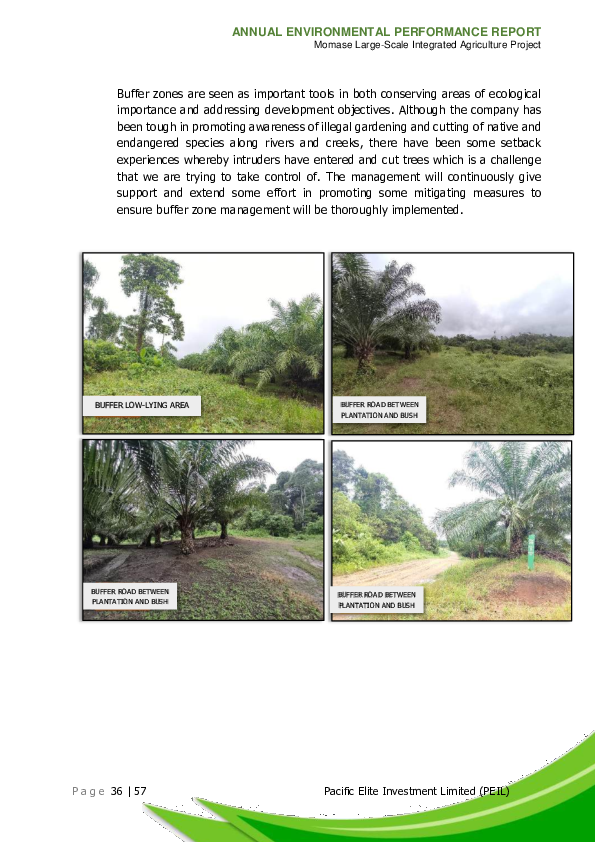

Buffer zones are seen as important tools in both conserving areas of ecological

importance and addressing development objectives. Although the company has

been tough in promoting awareness of illegal gardening and cutting of native and

endangered species along rivers and creeks, there have been some setback

experiences whereby intruders have entered and cut trees which is a challenge

that we are trying to take control of. The management will continuously give

support and extend some effort in promoting some mitigating measures to

ensure buffer zone management will be thoroughly implemented.

BUFFER LOW-LYING AREA BUFFER ROAD BETWEEN

PLANTATION AND BUSH

BUFFER ROAD BETWEEN

BUFFER ROAD BETWEEN

PLANTATION AND BUSH PLANTATION AND BUSH

P a g e 36 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

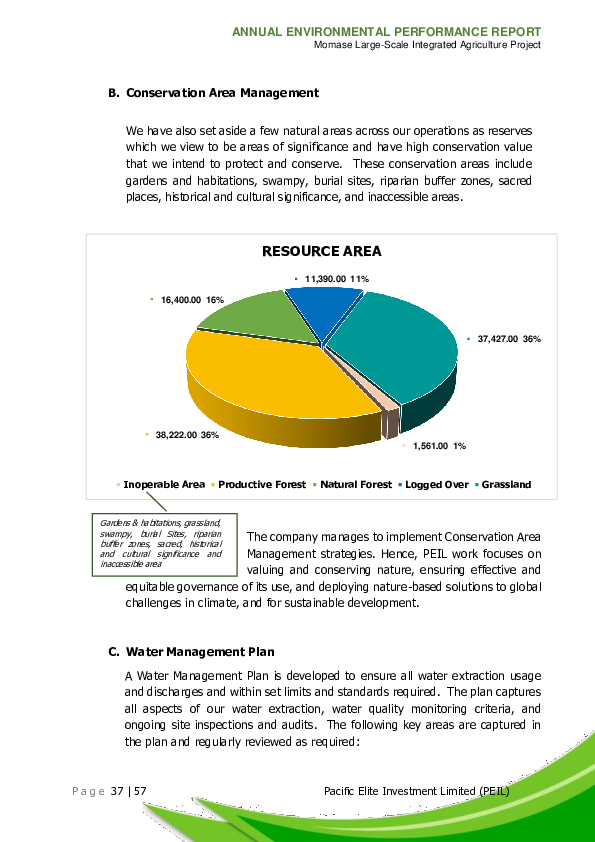

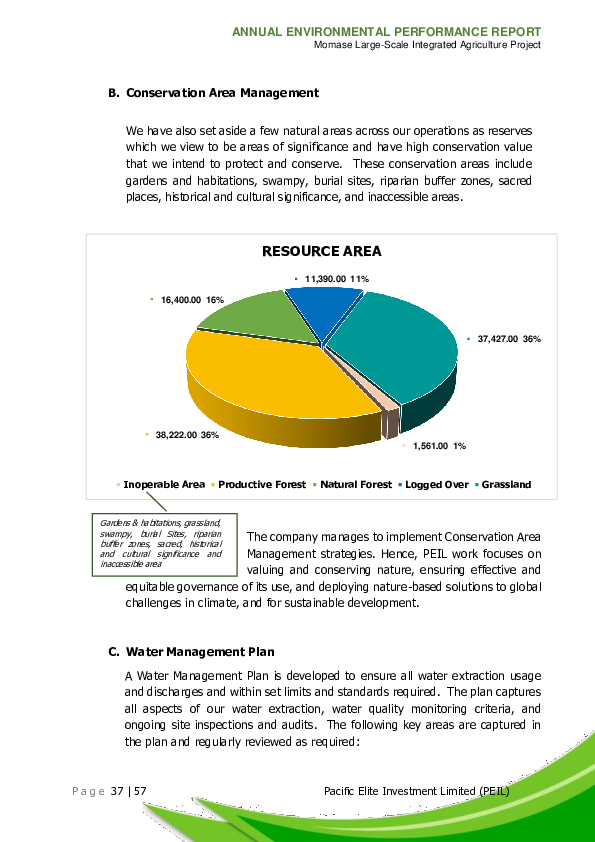

B. Conservation Area Management

We have also set aside a few natural areas across our operations as reserves

which we view to be areas of significance and have high conservation value

that we intend to protect and conserve. These conservation areas include

gardens and habitations, swampy, burial sites, riparian buffer zones, sacred

places, historical and cultural significance, and inaccessible areas.

RESOURCE AREA

11,390.00 11%

16,400.00 16%

37,427.00 36%

38,222.00 36%

1,561.00 1%

Inoperable Area Productive Forest Natural Forest Logged Over Grassland

Gardens & habitations, grassland,

swampy, burial Sites, riparian The company manages to implement Conservation Area

buffer zones, sacred, historical

and cultural significance and Management strategies. Hence, PEIL work focuses on

inaccessible area

valuing and conserving nature, ensuring effective and

equitable governance of its use, and deploying nature-based solutions to global

challenges in climate, and for sustainable development.

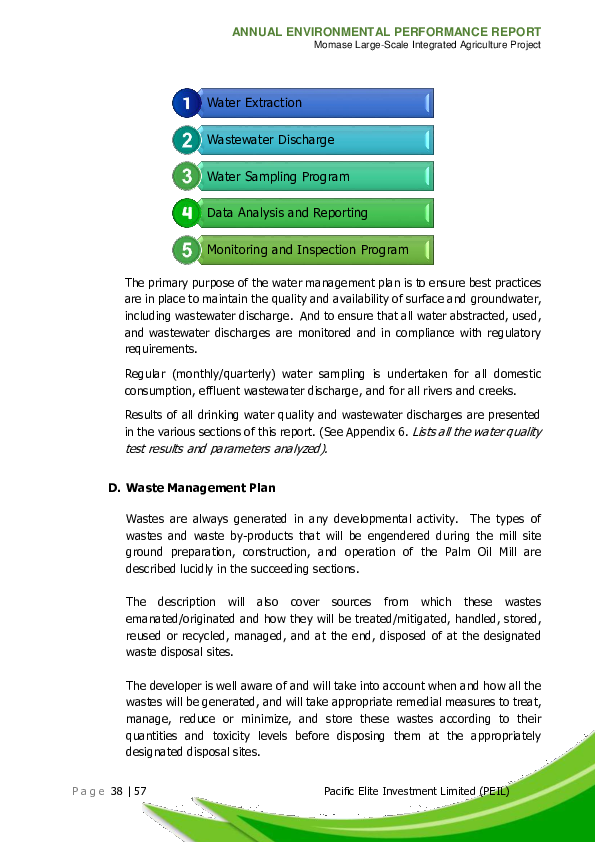

C. Water Management Plan

A Water Management Plan is developed to ensure all water extraction usage

and discharges and within set limits and standards required. The plan captures

all aspects of our water extraction, water quality monitoring criteria, and

ongoing site inspections and audits. The following key areas are captured in

the plan and regularly reviewed as required:

P a g e 37 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

Water Extraction

Wastewater Discharge

Water Sampling Program

Data Analysis and Reporting

Monitoring and Inspection Program

The primary purpose of the water management plan is to ensure best practices

are in place to maintain the quality and availability of surface and groundwater,

including wastewater discharge. And to ensure that all water abstracted, used,

and wastewater discharges are monitored and in compliance with regulatory

requirements.

Regular (monthly/quarterly) water sampling is undertaken for all domestic

consumption, effluent wastewater discharge, and for all rivers and creeks.

Results of all drinking water quality and wastewater discharges are presented

in the various sections of this report. (See Appendix 6. Lists all the water quality

test results and parameters analyzed).

D. Waste Management Plan

Wastes are always generated in any developmental activity. The types of

wastes and waste by-products that will be engendered during the mill site

ground preparation, construction, and operation of the Palm Oil Mill are

described lucidly in the succeeding sections.

The description will also cover sources from which these wastes

emanated/originated and how they will be treated/mitigated, handled, stored,

reused or recycled, managed, and at the end, disposed of at the designated

waste disposal sites.

The developer is well aware of and will take into account when and how all the

wastes will be generated, and will take appropriate remedial measures to treat,

manage, reduce or minimize, and store these wastes according to their

quantities and toxicity levels before disposing them at the appropriately

designated disposal sites.

P a g e 38 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

The environment management program comprises the following components,

to wit:

Identification of sources and types of waste;

Identification of specific waste products;

Waste control, containment, and minimization action

Waste storage and treatment method;

Waste handling and transportation method;

Final waste disposal method;

Collection and disposal frequency; and

Responsible personnel to do the tasks.

Appendix 7 shows the Waste Management Plan Details Matrix. It identifies

the environmental issues, the waste products/emissions, the possible sources,

and the environmental management options to be implemented to mitigate

adverse impacts.

WASTE:

Various wastes are generated as by-products from different activities, such as

wastes produced from the ground preparation of the mill site and plantation

site preparation, and construction and operation of the palm oil mill, plywood

plant and sawmill. To manage these wastes, PEIL, and the Contractor will use

mitigation methods and techniques (strategies/ mechanisms) to purposely

minimize and control these wastes. Excessive and toxic wastes will be

appropriately treated into simplicity and also to reduce their toxicity levels by

separating and retaining toxic elements and compounds from mixtures

(effluents), and disposed of at recommended disposal sites. Other recyclable

wastes will be reused, while hazardous wastes will be safely handled away

before their elimination. Non-biodegradable wastes (e.g. plastic litter) will

either be incinerated (burned) or, buried to avoid accidental contaminations,

and prevented from being transported into water courses during downpours

resulting in pollution, causing injuries, or becoming threats/risks to lives. Those

wastes to be buried in this case are garbage waste and putrefied wastes

including broken glass and metals.

The executives of the company have been involved in timber-related

operations, oil palm plantation development, and palm oil mill & timber

downstream processing operations outside and inside the country for many

years and are well aware of the different types of waste that are usually

P a g e 39 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

generated. Therefore, PEIL will always find appropriate ways and means and

continue to take remedial measures, to manage, treat (those wastes that

warrant treatment), and simplify (especially raw biodegradable wastes such as

sewerage) before disposing them into the environment

1. NATURE OF SPECIFIC WASTE

Determination of the waste products and identification of their nature

generated from all phases of the project operation is a vital component of

any waste management program. The nature of specific waste is generally

classified into Biodegradable, Non-biodegradable, and Toxic waste. Waste

Classification is the important first step and is very relevant in finding and

implementing appropriate waste treatment and disposal methods.

Appendix 8: Shows the Nature of the Specific Waste Products Matrix.

a) Biodegradable Waste – These are the wastes that will be able to

decompose by bacteria (aerobic or un-aerobic), fungi, and other

biological means. The residues of decomposition mustn't be harmful

or toxic to living organisms and man. These wastes, if fully

decomposed, are good soil amelioration materials that will improve

their physical and chemical properties. However, this specific waste

might render negative environmental effects (e.g. foul odor) if not

properly managed.

Most organic wastes such as papers, wood debris, empty oil palm

bunches, sludge, discarded food, food preparation-related wastes,

and others are a few examples of so-called biodegradable wastes.

b) Non-biodegradable Waste – This type of waste has the nature of

not being decomposed by biological means. Specific examples are

scrap iron, junk machinery/parts, cables, wires, containers (bottles,

plastic, glass, and metal), and polyethylene bags.

c) Toxic Waste – This specific waste is commonly the product of

industrial or commercial processes, which is capable of causing

injuries or possible death to micro and macro living organisms or harm

to human health when exposed, ingested, or inhaled. The waste

includes fuel/oil spillage, used oils and lubricants, paints, chemicals

for timber treatments, discarded batteries, and contaminated storm

waters, among others.

P a g e 40 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

2. METHODS OF WASTE TREATMENT AND DISPOSAL

PEIL employed three methods of Waste Management to handle the

waste products derived from the various operational activities such as

mill/plant & plantation site ground preparation, Staff and Workers

Accommodation, Palm Oil Mill/timber processing plant Construction, and

Operation. The waste treatment methods that were applied include

incineration, surface dumping, wastewater aerobics and anaerobic

settling ponds, and landfills. However, before the disposition of the

different solid waste into the collection bin, the company implemented a

solid waste segregation strategy. At the source, PEIL provided two kinds

of collection bins or rubbish collection areas, one for biodegradable and

another one for non-biodegradable wastes for domestic and workshop

wastes.

a) Incineration Method – This method is simply burning all

combustible waste materials such as plastic bags/wrappers,

cardboard, scratch papers, wood debris (off-cuts, sawdust), used

tires & tubes, and other solid combustible waste materials in a

designated incineration site.

The incineration site was established far from the housing and other

support facilities, villages, and watercourses after considering other

factors such as the wind direction, ground slope, and accessibility.

The incineration site was constructed approximately 100 meters or

more away from the quarters and very far from any villages. It has

an area of about 120m2.

b) Surface Dumping Method – Wastes products such as soil debris,

rocks debris, uncontaminated containers (drums, etc.), metal

scraps/junk machinery, and parts were properly disposed of in the

designated open surface dumping site.

All surface dumping sites were established in a distant place away

from the village, housing, and other support facilities as well as

watercourses. It is also located in a secured and relatively flat area

where water-logging is avoided.

P a g e 41 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

The surface dumping area is 10 meters in width and 10 meters in

length or 100m2 in area which was established adjacent to the

incineration site.

c) Pond Method – Effluent and sludge generated in the Palm Oil Mill

operation comprised of wastewater (washing of FFB and cooking of

fruits), pulp, and residual oil were directed to the series of ponds (a

total of 10 units) (cooling pond, acidification pond, anaerobic pond,

aerobic pond, facultative pond & finally, the settling pond) were

constructed by the company. The size of the pond depends on the

volume of waste and the number of days that these wastes will stay

in the pond during the treatment process.

At the moment, the company has established a 45tonne/hour

capacity upgradable to a 60tonne/hour oil palm mill. Therefore, the

effective waste-holding capacities of the pond to be constructed will

range from 10,800m3 to 18,000m3.

d) Landfill Method – Human waste disposal is based on the landfill

method after the septic tanks are full. Toilets and septic tanks are

constructed as storage of all human wastes such as feces and excreta

and wastes that flow in the kitchen sinks. The staff houses and

workers’ quarter have their respective built-in toilets and septic tanks

for that purpose, hence not indicated as separate buildings.

Several conditions were satisfied during the establishment of the

landfills, as follows:

The area is impermeable to prevent the leaking/seeping of

liquid waste into nearby watercourses (rivers, streams, and

creeks);

It is at least 100 meters from maximum water inundation and

at least 1 meter above maximum groundwater height;

It is not readily flooded during the wet season and heavy rain;

and

The year-round wind direction is away from the inhabitants of

the nearby camps and villages.

P a g e 42 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

3. POTENTIAL WASTE SOURCES

The activities associated with the Momase Large-scale Integrated

Agriculture Project operations have the potential to generate waste as

follows:

Tree salvaging wastes

Plantation site preparation

Ground preparation for the mill/plant site;

Construction of Palm Oil Mill & timber processing plants;

Base camp/transit camps operations (staff and workers

housing facilities and other support facilities);

Jetty/wharf areas;

Workshops and generator facilities;

Fuel depots and lubricant storage facilities;

Palm oil extraction and processing plant operations;

Timber Downstream Processing Operations and

Landfill, Incineration, and Surface Dumping sites.

The wastes that are generated from these activities consist of solid waste,

liquid waste, gaseous emission, noise emission, and odor emission.

These wastes are further classified into Biodegradable, Non-

biodegradable, or Toxic.

Natural components such as sediments, silts, and other earthly materials

with organic matter are other forms of environmental contaminants.

Rainfall runoff containing sediments is a significant source of waste within

the projects’ operations. Such materials may enter the different water

body networks when their foundations or natural environmental settings

have been disturbed so that their inert bonding is forcefully loosened or

broken up. The quantity of sediments in rainfall-runoff per year is directly

proportional to the amount of annual rainfall of the project site, the timing

of the implementation of different projects’ activities, and the strategies

employed in the control of sedimentation.

Sedimentation and siltation of any given water body are one of the basic

natural causes which often account for severe impacts upon the

environment particularly on aquatic/marine organisms, as well as human

beings living in any part of a given downstream where landslides and

heavy erosion occurred. For instance, too much siltation and high

P a g e 43 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

concentration of suspended solids affect the gills of the fish, and

absorbing too much heat from sunlight will result in increased water

temperature and oxidation, eventually resulting in a reduction of fish’s

food sources.

The company and its contractor are well aware of these things and avoid

as much as possible too much extensive disturbance with the natural

environmental settings so that massive soil erosions which contribute to

the heavy sedimentation and pollution of any type of water bodies are

avoided. Hence, proper timing shall be adopted in the conduct of tree

salvaging operation, ground preparation for the mill/plant sites, and

access road network.

To minimize further contamination due to soil erosion, a drainage system

will be built properly to divert and channel the water surface runoff during

heavy rain to vegetated portions to avoid overland flows and flooding,

thereby reducing the severity or degree of erosion.

Wastes generated from the palm oil mill & timber processing plants

construction and operation can also be categorized as Domestic (non-

industrial) Wastes and Industrial Wastes depending on their sources and

characteristics.

a. Domestic Wastes. Domestic wastes mainly refer to sludge, kitchen

waste, refusal, and putrefied waste (mostly food scrap), textiles,

plastic litter, glass/bottles, papers, discarded furniture &

cartons/cardboards, personal hygiene/grooming empty containers,

empty cans, lubricants, laundry & kitchen washed-water, storm

waters, cleaners, pesticides, and sewerage.

These domestic wastes, except for sewerage and washed waters, will

be separated and collected in wet and dry garbage bins and

segregated into biodegradable or non-biodegradable or recyclable,

respectively, before handling and transportation to recommended

disposal sites. The wet garbage and fast biodegradable will be

dumped or buried in pits away from the water courses and residential

areas while the dry garbage shall be disposed at the dump sites or

incinerated away from populations.

As for sewerage, latrines (toilet pits) for the employees will be

respectively dug at sites well away from watercourses at higher

P a g e 44 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

grounds where the water table is not too close to the surface to avoid

contamination of the underground waters. As soon as the pits have

been filled-up (full) with sewerage, they will be covered with soil, and

dig a new pit for use. These latrines will be fortified and covered well

to avoid flooding and prevent pests such as flies, cockroaches,

mosquitoes, and other pathogenic/vector organisms to breed and

thrive in these pits.

Also, septic systems will be put in place for use and de-sludge

whenever they have been filled-up. The de-sludge materials will be

transported away and disposed of in the landfill site.

b. Industrial Wastes. Industrial wastes are the by-products and refuse

generated from tree salvaging and log pond operations, workshops,

fuel depots and lubricants storage facilities, generator set facilities,

palm oil mill and timber processing plants, vehicles, heavy equipment,

and machinery.

These wastes include fuel, oil, and lubricants spillage; waste and used

fuel, oil, and lubricants; used fuel and oil filters; solvents; toxins;

chemical mixture/solutions; pesticides/insecticides; storm waters;

industrial washed-waters; paint residues; discarded equipment and

parts; cleaners; sewerage; empty fruit bunches, palm kernel shells,

mesocarp fibers, sawdust; trimmings/wood off-cuts; slabs; discarded

bolts & nuts; used welding rods; iron rods & scrap metals; batteries;

empty drum & other containers; tires & tubes; and wires & cables.

Those wastes in the liquid state or as mixtures and solutions will be

properly channeled through the use of pipes and drainage systems

into either sewerage treatment ponds (as for sewerage) or septic

systems, and also separate septic systems for the toxic wastes alone.

All toxic wastes such as oils, fuels, treated chemical solutions,

cleaners, paint residues, contaminated storm waters, lubricants, and

other industrial wastewater will be properly contained and, channeled

into separate septic tanks to be collected there for recycling, reuse,

or randomly removed off in a recommended manner to avoid seepage

and accidental pollution.

Appendix 9. Shows the Waste Management Program. It identifies

the sources and the types of waste; the specific waste products; the

waste control, and containment. And minimization strategies; waste

P a g e 45 | 57 Pacific Elite Investment Limited (PEIL)

�

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT

Momase Large-Scale Integrated Agriculture Project

storage and treatment methods; waste handling and transportation;

the final waste disposal method; the waste collection and disposal

frequency; and the responsible personnel for the waste management

implementation.

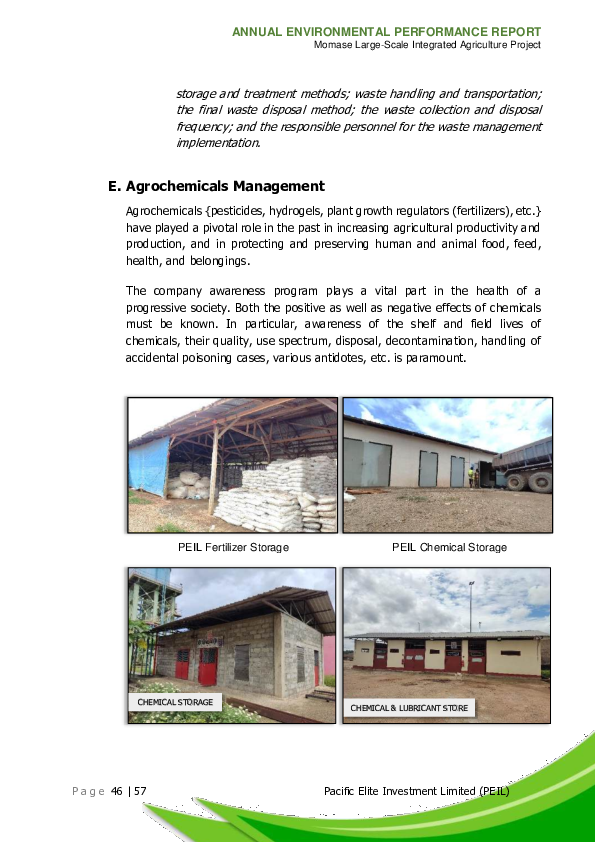

E. Agrochemicals Management

Agrochemicals {pesticides, hydrogels, plant growth regulators (fertilizers), etc.}

have played a pivotal role in the past in increasing agricultural productivity and

production, and in protecting and preserving human and animal food, feed,

health, and belongings.

The company awareness program plays a vital part in the health of a

progressive society. Both the positive as well as negative effects of chemicals

must be known. In particular, awareness of the shelf and field lives of

chemicals, their quality, use spectrum, disposal, decontamination, handling of

accidental poisoning cases, various antidotes, etc. is paramount.

PEIL Fertilizer Storage PEIL Chemical Storage

CHEMICAL STORAGE

CHEMICAL & LUBRICANT STORE

P a g e 46 | 57 Pacific Elite Investment Limited (PEIL)

�

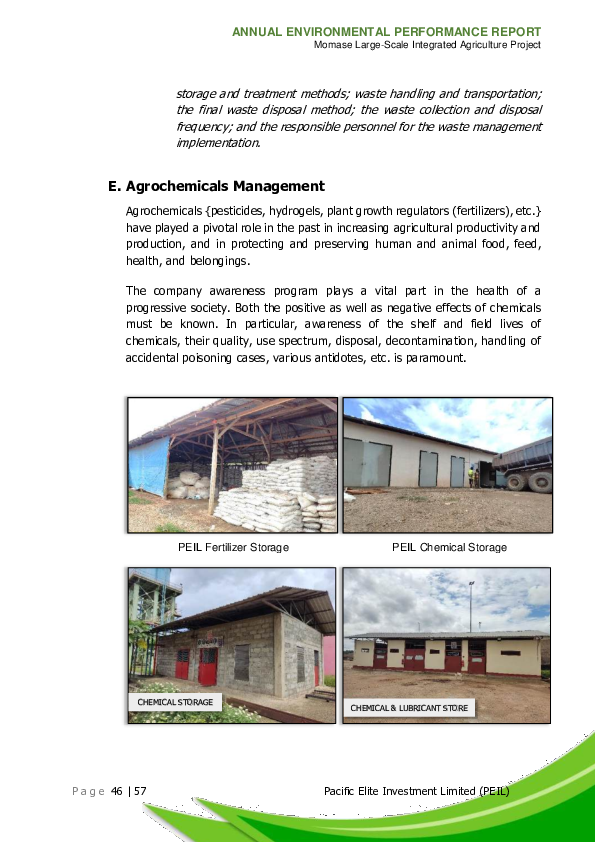

ANNUAL ENVIRONMENTAL PERFORMANCE REPORT